Flame-retardant and drippage-free ceramization silicon rubber and preparation method thereof

A technology of vitrified silicone rubber and thermally vulcanized silicone rubber, which is applied in the field of silicone rubber composite materials, can solve the problems of difficult control of formula ratio, material hardness needs to be improved, complex formula, etc., and achieve good physical and mechanical properties, superior performance and simple process controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

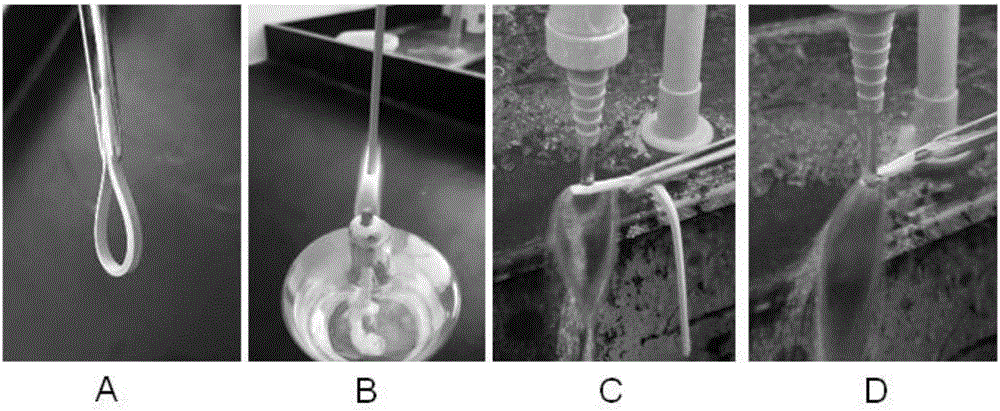

Image

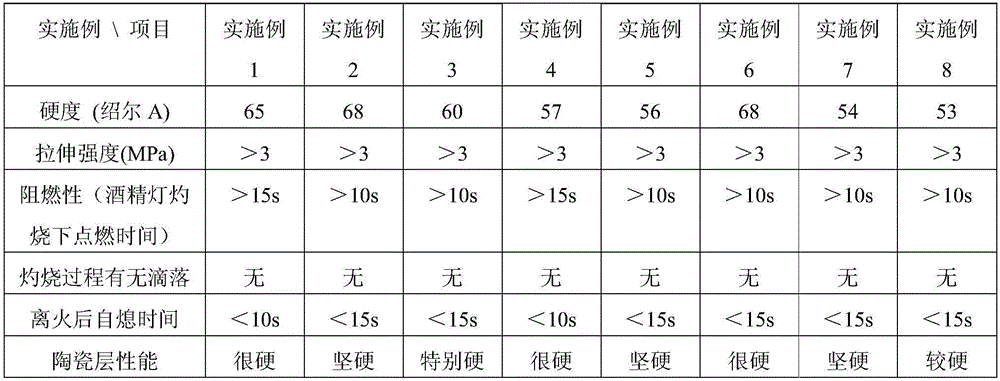

Examples

Embodiment Construction

[0016] Technical scheme of the present invention is as follows:

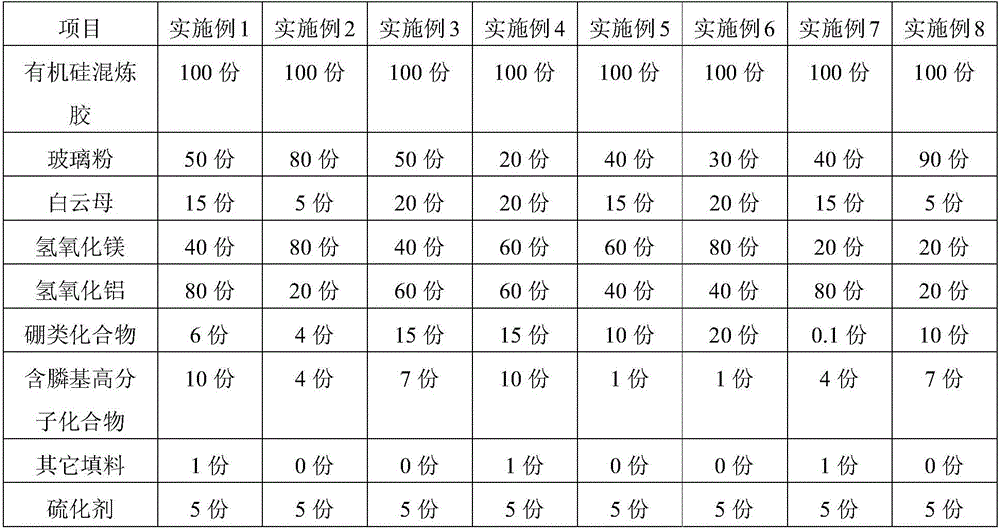

[0017] A flame-retardant, non-dripping, ceramizable silicone rubber, comprising the following raw materials in parts by weight:

[0018] 100 parts of silicone rubber compound, 1-10 parts of vulcanizing agent, 100-500 parts of ceramic powder;

[0019] The ceramizable powder includes the following components in parts by weight: 1-120 parts of glass powder, 1-20 parts of muscovite, 1-200 parts of magnesium hydroxide, 1-200 parts of aluminum hydroxide, and 0.1-200 parts of boron compounds. 50 parts, 0.1-20 parts of phosphine-containing polymer compound.

[0020] According to the present invention, preferably, the flame-retardant, non-dripping, ceramizable silicone rubber also includes 0-100 parts of other fillers or additives, more preferably 1-99 parts; the other fillers or additives are Various additives that enhance or do not significantly reduce the performance of silicone rubber, including thermal oxygen stab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com