Preparation method of magnesium alloy

A magnesium alloy and alloy technology, which is applied in the field of preparation of non-ferrous metal magnesium alloys, can solve the problems of backward detection methods, simple equipment, and high labor intensity of workers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0104] The present invention will be further described below in conjunction with the accompanying drawings.

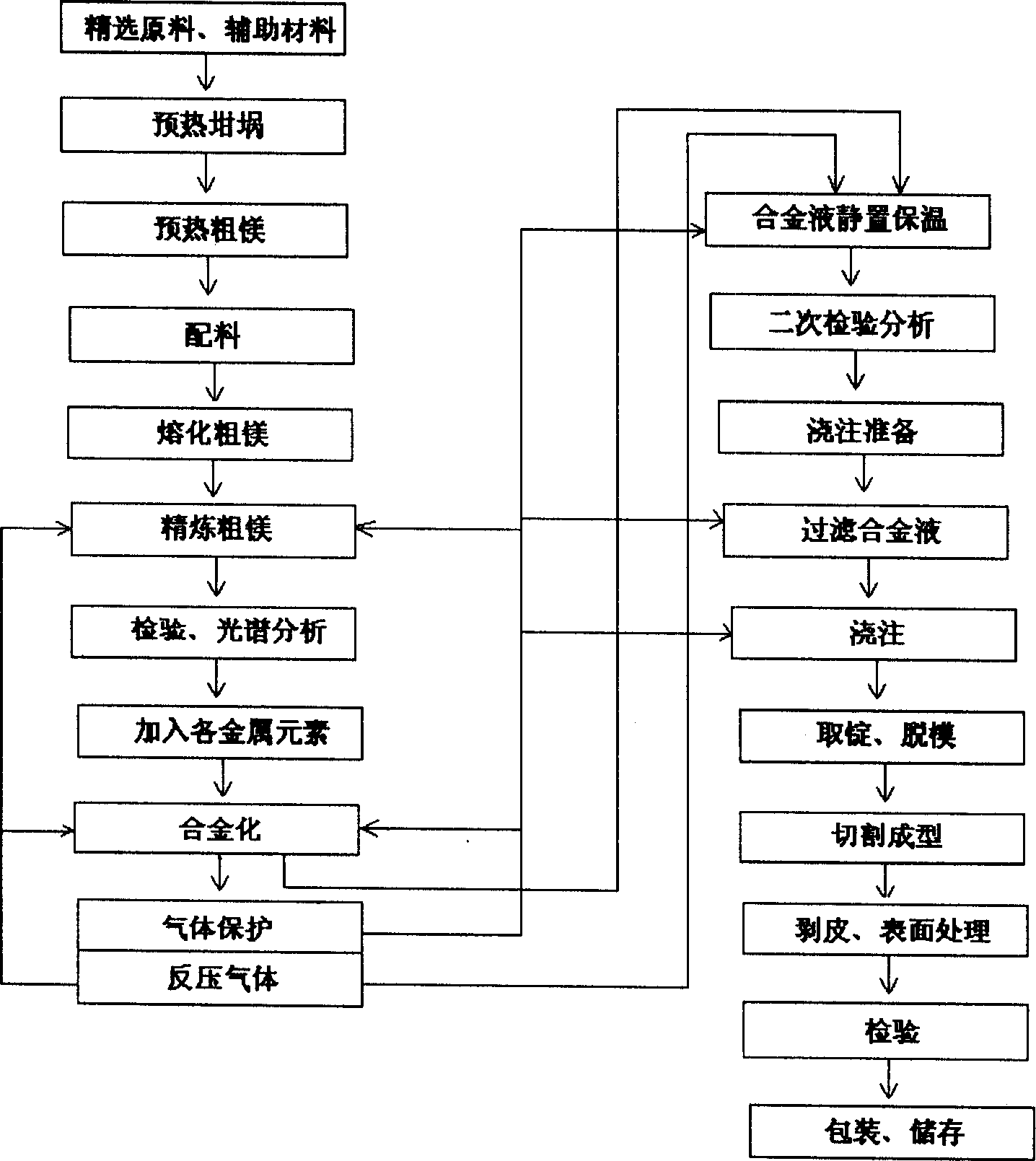

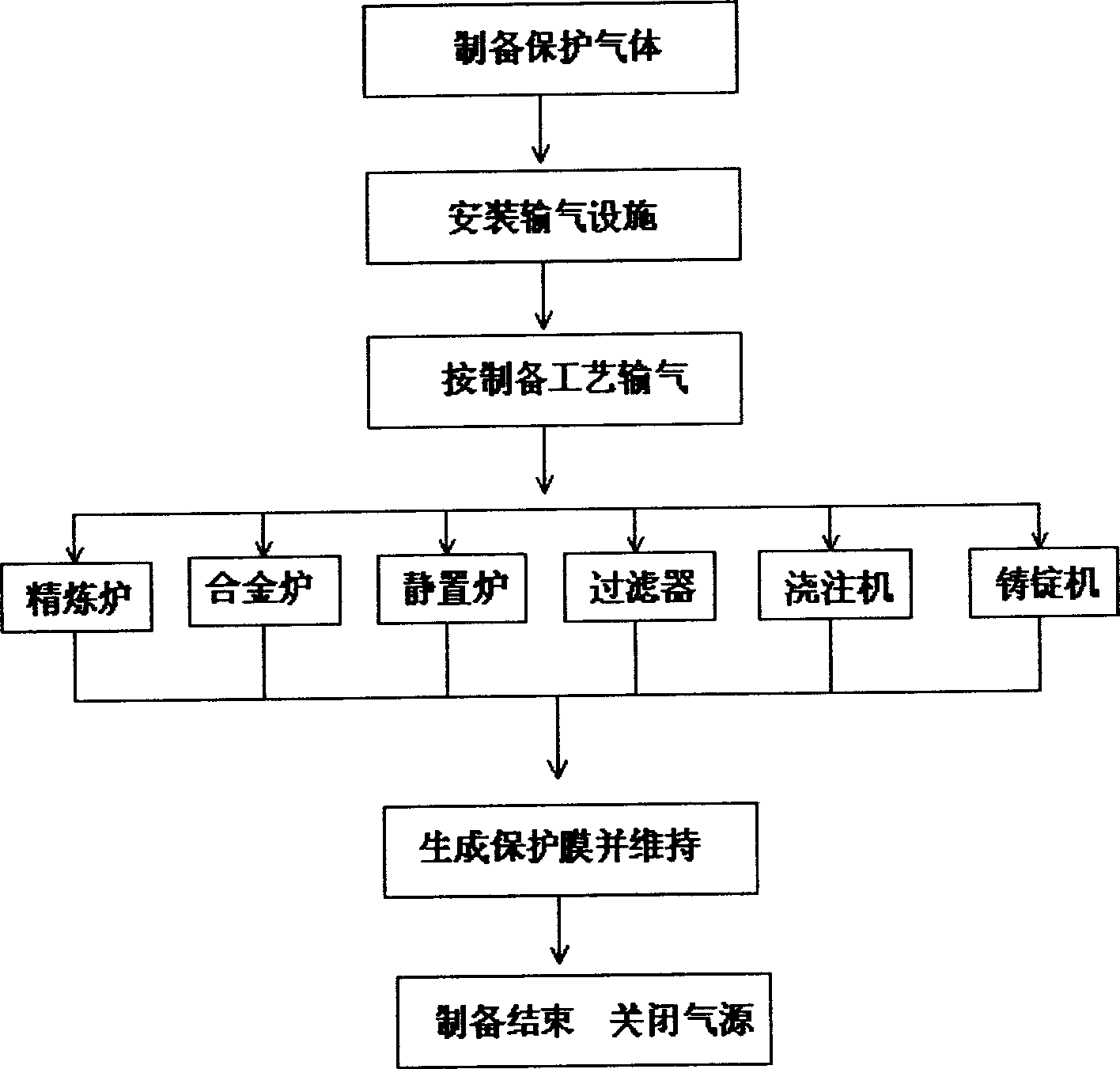

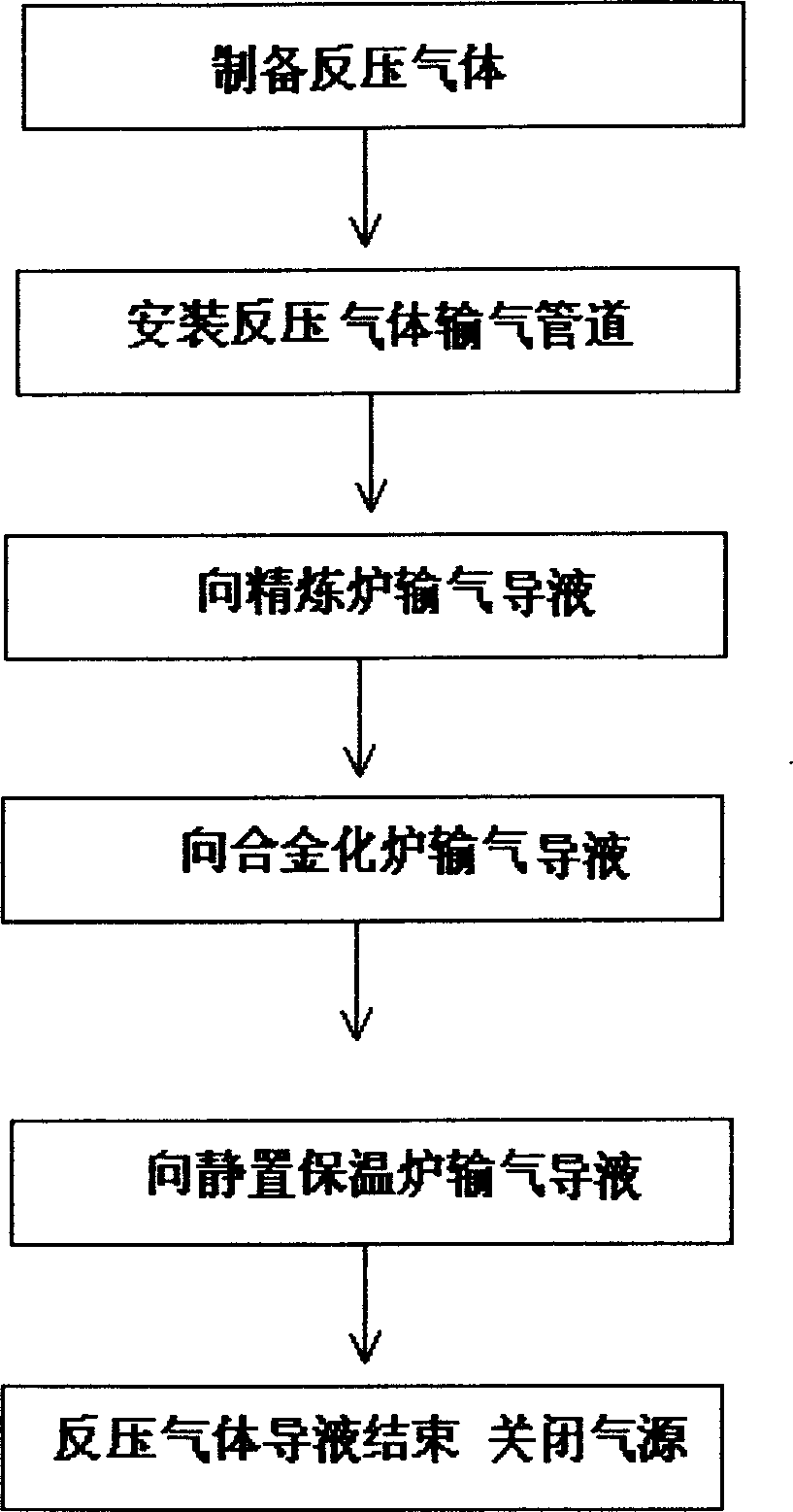

[0105] figure 1 , 4, 5, and 6, the implementation steps of the magnesium alloy preparation method are as follows:

[0106] Various equipment and valves for preparing magnesium alloys are placed in stop and closed positions, and are in the quasi-working state before preparation.

[0107] The crude magnesium is placed in the feeding car 17, and the raw material is sent to the conveying frame 19 through the conveying platform 18 for use in smelting.

[0108] Turn on the preheating furnace 1, and the preheating temperature of the crucible in the preheating furnace 1 is 400°-500°C. Put the flux into the bottom of the crucible, and then add the preheated coarse magnesium according to the proportioned weight, the preheating temperature is 120°-150°C, cover the lid 69, and keep it warm for a certain period of time.

[0109] After the crude magnesium is preheated, the crude ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com