Inorganic flame retardant for wrapping polystyrene granules

A technology of polystyrene particles and inorganic flame retardants, which is applied in the field of inorganic flame retardants, can solve problems such as easy pollution of the environment, and achieve the effect of less environmental pollution and less addition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

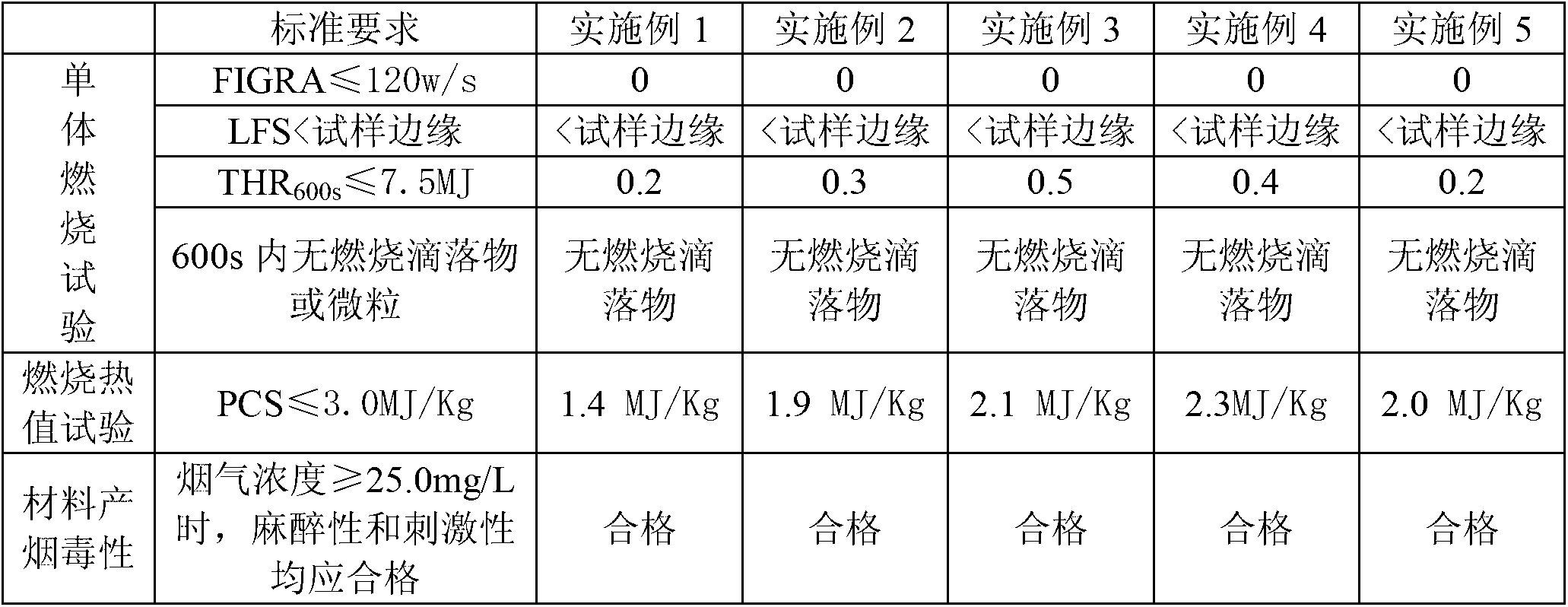

Examples

Embodiment 1

[0017] Using melamine as a carrier, weigh 20 parts of aluminum hydroxide, 10 parts of iron oxide red, 3 parts of n-pentane, 15 parts of expanded graphite, 5 parts of silica sol, and 2 parts of γ-aminopropyl triethoxy silane and 2 parts zirconium dioxide. When preparing the flame-retardant polystyrene board, add the above-mentioned inorganic materials into the mixer in sequence, and stir evenly for 6 minutes, so that the flame retardant becomes viscous and can wrap the polystyrene particles.

[0018] After adding 10% curing agent to the flame retardant, mix it evenly with the pre-expanded polystyrene masterbatch particles according to the weight ratio of 1:50, so that the flame retardant slurry is wrapped in the pre-expanded polystyrene masterbatch The surface of the material particles is dried at 65~75°C using fluidized bed drying equipment; then the wrapped particles are filled into the preheated sheet forming machine, and the mold is heated by steam at 95~110°C to keep the p...

Embodiment 2

[0020] Using melamine as a carrier, weigh 15 parts of aluminum hydroxide, 5 parts of iron oxide red, 2 parts of isopentane, 10 parts of expanded graphite, 3 parts of silica sol, 1 part of titanate coupling agent and 1 part by weight. parts zirconium dioxide.

[0021] When preparing the flame-retardant polystyrene board, add the above-mentioned inorganic materials into the mixer in sequence, and stir evenly for 5 minutes, so that the flame retardant becomes viscous and can wrap the polystyrene particles.

[0022] After adding 10% curing agent to the flame retardant, mix it evenly with the pre-expanded polystyrene masterbatch particles according to the weight ratio of 1:40, so that the flame retardant slurry is wrapped in the pre-expanded polystyrene masterbatch The surface of the material particles is dried at 65~75°C using fluidized bed drying equipment; then the wrapped particles are filled into the preheated sheet forming machine, and the mold is heated by steam at 95~110°C ...

Embodiment 3

[0024] Using the epoxy resin diluted with 5% pure water as the carrier, weigh 25 parts of aluminum hydroxide, 15 parts of iron oxide red, 4 parts of isopentane, 20 parts of expanded graphite, 8 parts of silica sol 3 Parts of γ-aminopropyltriethoxysilane and 3 parts of zirconium dioxide.

[0025] When preparing the flame-retardant polystyrene board, add the above-mentioned inorganic materials into the mixer in sequence, and stir evenly for 7 minutes, so that the flame retardant becomes viscous and can wrap the polystyrene particles.

[0026] After adding 10% curing agent to the flame retardant, mix it evenly with the pre-expanded polystyrene masterbatch particles according to the weight ratio of 1:30, so that the flame retardant slurry is wrapped in the pre-expanded polystyrene masterbatch The surface of the material particles is dried at 65~75°C using fluidized bed drying equipment; then the wrapped particles are filled into the preheated sheet forming machine, and the mold is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com