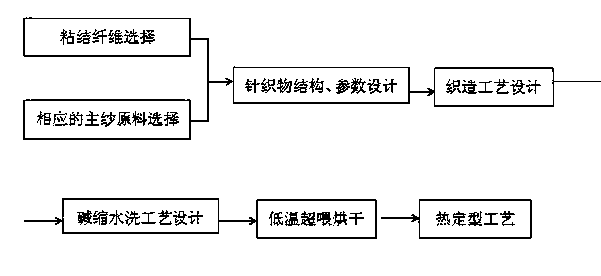

Processing process of stable-dimension knitted fabrics

A dimensionally stable and processing technology, applied in the direction of knitting, weft knitting, fabric surface trimming, etc., can solve the problems of extensibility, elasticity, moisture absorption and breathability than knitted fabrics, poor dimensional stability, curling and other problems , to achieve good dimensional stability, achieve dimensional stability, reduce shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

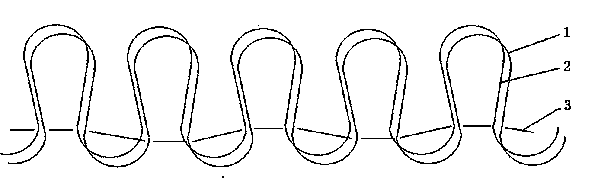

[0020] combine figure 1 , in this embodiment, 105dtex / 36F sheath-core type hot-melt polyester yarn is used as the bonding fiber, and its surface melting point is 170°C; 17.8tex cotton yarn is used as the main yarn raw material (strength and elasticity are the bonding fiber of the technical solution of the present invention) It has little influence on the raw material of the main yarn, so it is omitted in this embodiment). Steam the raw material of the main yarn first, and control the temperature of the steamed yarn at 95°C. After 30 minutes of treatment, cool the raw material of the main yarn to room temperature. Weaving is carried out on the machine, and the bonding fiber is interwoven with the main yarn raw material, among which, the combined figure 2 , the adding method of bonding fiber is: using bonding fiber, that is, sheath-core hot-melt polyester yarn as the ground yarn, the amount of bonding fiber added is 15%, 17.8tex cotton yarn as the veil, 58tex cotton yarn as th...

Embodiment 2

[0024]The settings and principle of this embodiment are the same as those of Embodiment 1, the difference is that in this embodiment, 70dtex / 24F sheath-core type hot-melt polyester filament is used as the bonding fiber, and its surface melting point is 170°C; colored polyester filament is used as the bonding fiber. The raw material of the main yarn has a denier of 200dtex. Weaving is carried out on a 34-inch, 22 needles / inch, 72-way double-sided jacquard circular machine, and the bonding fibers are in the form of plating (filling yarn is a kind of pattern organization of knitted fabrics, and all coils or some of its coils are made of two Composed of one or more yarns, the plaiting organization can be divided into weft knitting and warp knitting, single-sided and double-sided, plain color and pattern) and the main yarn raw material is interwoven, and the amount of binder fiber added is 25%. The weaving method adopts two-color double-sided incomplete jacquard (among them, accord...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com