Preparation method for soundproof hard PVC floor

A floor and hard technology, applied in chemical instruments and methods, lamination devices, lamination auxiliary operations, etc., can solve the problems of easy warping, peeling, high preparation cost, poor adhesion of each layer, etc. To achieve the effect of good sound insulation, good texture and good flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

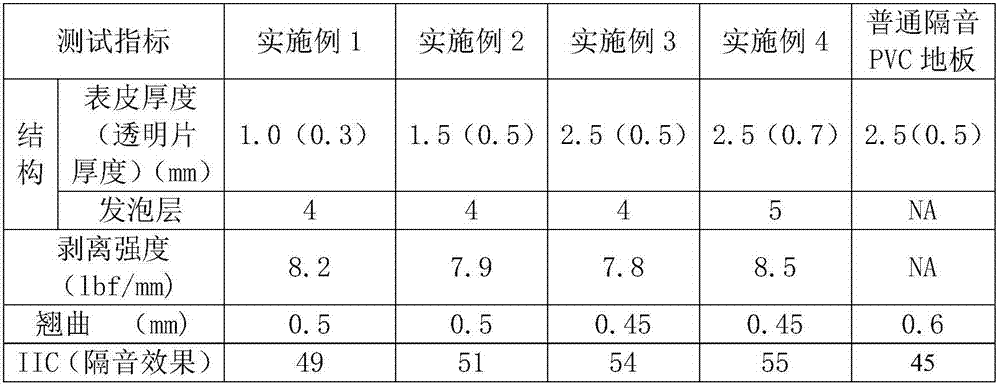

Examples

Embodiment 1

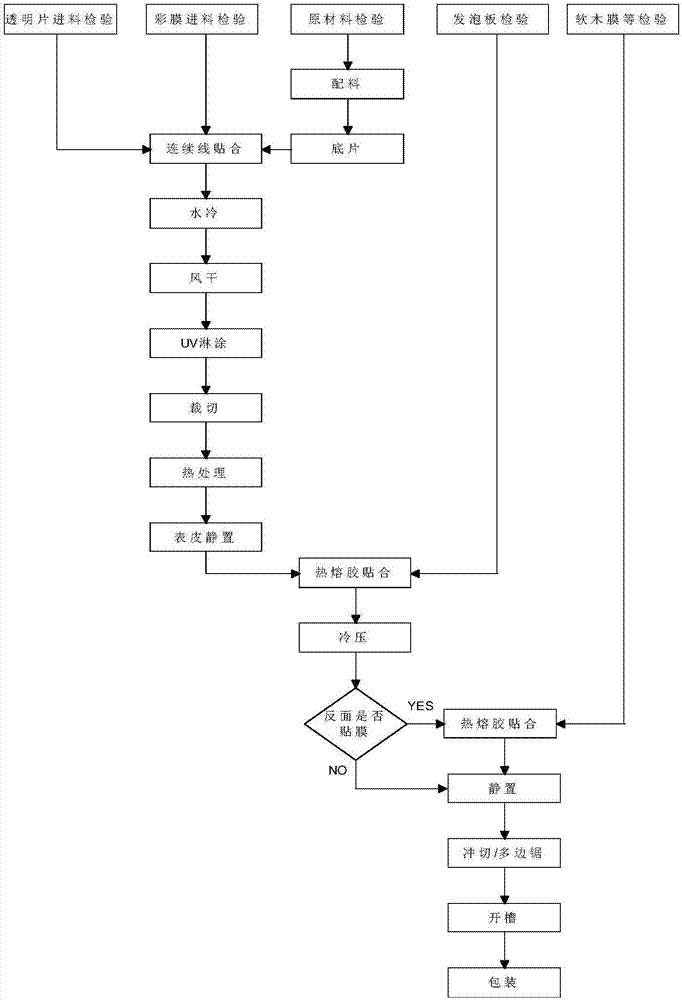

[0027] Please refer to figure 1 , a preparation method of a sound-insulating rigid PVC floor, specifically, a PE foam board with a thickness of 1.0mm is adhered to the back of an ordinary PVC floor with 4 layers of foam material for preparation, comprising the following steps:

[0028] (1) Film production: firstly, after the raw materials are inspected and qualified, according to the ordinary PVC floor formula and film production method, it is drawn through the process of cold mixing and hot mixing, banburying, four-roll calendering, cooling and winding of the compounding materials. Negative films of various required specifications and thicknesses;

[0029] (2) Continuous line bonding: After the temperature rises to the specified value, the material is worn layer by layer in the order of negative film, surface layer, color film, and transparent sheet. The number of layers of each layer depends on the thickness requirements of the prepared floor and the thickness of the transpa...

Embodiment 2

[0043] Please refer to figure 1 , a method for preparing a sound-insulating rigid PVC floor, specifically, a PE foam board with a thickness of 2.0mm is attached to the back of an ordinary PVC floor with 4 layers of foaming material for preparation, including the following steps:

[0044] (1) Film production: firstly, after the raw materials are inspected and qualified, according to the ordinary PVC floor formula and film production method, it is drawn through the process of cold mixing and hot mixing, banburying, four-roll calendering, cooling and winding of the compounding materials. Negative films of various required specifications and thicknesses;

[0045] (2) Continuous line bonding: After the temperature rises to the specified value, the material is worn layer by layer in the order of negative film, surface layer, color film, and transparent sheet. The number of layers of each layer depends on the thickness requirements of the prepared floor and the thickness of the trans...

Embodiment 3

[0059] Please refer to figure 1 , a method for preparing a sound-insulating rigid PVC floor, specifically, a PS foam board with a thickness of 1.0mm is attached to the back of an ordinary PVC floor with 4 layers of foaming material for preparation, including the following steps:

[0060] (1) Film production: firstly, after the raw materials are inspected and qualified, according to the ordinary PVC floor formula and film production method, it is drawn through the process of cold mixing and hot mixing, banburying, four-roll calendering, cooling and winding of the compounding materials. Negative films of various required specifications and thicknesses;

[0061] (2) Continuous line bonding: After the temperature rises to the specified value, the material is worn layer by layer in the order of negative film, surface layer, color film, and transparent sheet. The number of layers of each layer depends on the thickness requirements of the prepared floor and the thickness of the trans...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com