Outdoor uvioresistant fabric suitable for summer

An anti-ultraviolet, fabric technology, applied in the direction of biochemical fiber treatment, fiber chemical characteristics, cellulose/protein conjugated rayon, etc., to achieve the effect of simple preparation method, comfortable wearing and low transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

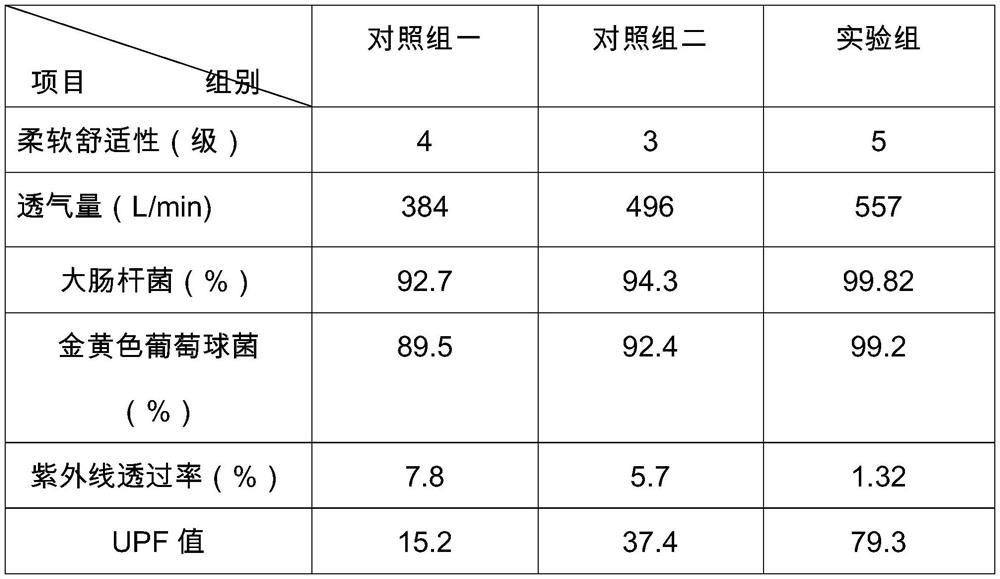

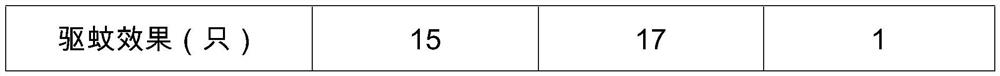

Examples

Embodiment 1

[0026] An anti-ultraviolet fabric suitable for summer outdoors is made of the following materials by weight: 80 parts of cotton fiber, 20 parts of bamboo charcoal fiber, 5 parts of nano-silver, 3 parts of polyethylene glycol, 1 part of glass fiber, tourmaline powder 3 parts, 1 part of simethicone oil, 2 parts of titanium dioxide, 2 parts of ceramic powder, 6 parts of silk fibroin, 10 parts of mosquito repellent and 68 parts of deionized water; the mosquito repellent consists of 3 parts of peppermint, citronella 1 part, 1 part of clove, 2 parts of orange peel and 6 parts of ethanol.

[0027] A preparation method suitable for outdoor anti-ultraviolet fabric in summer, comprising the following steps:

[0028] 1) Take 5 parts of nano-silver, 3 parts of tourmaline powder, 2 parts of titanium dioxide, 1 part of glass fiber and 2 parts of ceramic powder to remove impurities, and then mix 1 part of glass fiber, 3 parts of tourmaline powder, 2 parts of titanium dioxide and ceramic powd...

Embodiment 2

[0036] An anti-ultraviolet fabric suitable for summer outdoors is made of the following materials in proportion by weight: 70 parts of cotton fiber, 30 parts of bamboo charcoal fiber, 7 parts of nano silver, 5 parts of polyethylene glycol, 3 parts of glass fiber, tourmaline powder 5 parts, 3 parts of simethicone oil, 4 parts of titanium dioxide, 3 parts of ceramic powder, 8 parts of silk fibroin, 15 parts of mosquito repellent and 70 parts of deionized water; the mosquito repellent consists of 5 parts of peppermint, citronella 3 parts of cloves, 3 parts of cloves, 4 parts of orange peel and 8 parts of ethanol.

[0037] A preparation method suitable for outdoor anti-ultraviolet fabric in summer, comprising the following steps:

[0038] 1) Take 7 parts of nano-silver, 5 parts of tourmaline powder, 4 parts of titanium dioxide, 3 parts of glass fiber and 3 parts of ceramic powder to remove impurities, and then mix 3 parts of glass fiber, 5 parts of tourmaline powder, 4 parts of ti...

Embodiment 3

[0046] An anti-ultraviolet fabric suitable for summer outdoors is made of the following materials by weight: 75 parts of cotton fiber, 25 parts of bamboo charcoal fiber, 6 parts of nano-silver, 4 parts of polyethylene glycol, 2 parts of glass fiber, tourmaline powder 4 parts, 2 parts of simethicone oil, 3 parts of titanium dioxide, 2.5 parts of ceramic powder, 7 parts of silk fibroin, 13 parts of mosquito repellent and 69 parts of deionized water; the mosquito repellent consists of 4 parts of peppermint, citronella 2 parts, 2 parts of cloves, 3 parts of orange peel and 7 parts of ethanol.

[0047] A preparation method suitable for outdoor anti-ultraviolet fabric in summer, comprising the following steps:

[0048] 1) Take 6 parts of nano-silver, 4 parts of tourmaline powder, 3 parts of titanium dioxide, 2 parts of glass fiber and 2.5 parts of ceramic powder to remove impurities, then mix 2 parts of glass fiber, 4 parts of tourmaline powder, 3 parts of titanium dioxide and ceram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com