Powdered soybean protein material, and processed meat product using same

A soybean protein and powder technology, applied in vegetable protein processing, food science and other directions, can solve the problems of increased viscosity of dipping solution, difficult injection, and high viscosity of soybean protein material, and achieves good operability, good transparency, and rosy and bright appearance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

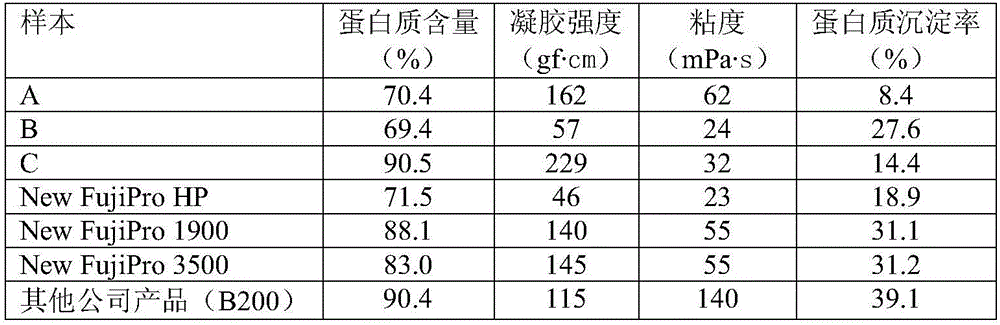

manufacture example 1

[0105] Add 10 times the amount of water to 10 kg of low-denatured defatted soybeans, adjust the pH value to 7.0 with sodium hydroxide, and carry out 300 °C at a temperature of 50 ° C while stirring with a high-speed mixer (manufactured by Tokikuki Kagaku Kogyo Co., Ltd.). Minutes of extraction, centrifugation at 3,000×g to remove okara, to obtain defatted soymilk.

[0106] The obtained defatted soymilk was further centrifuged at 5,000×g to obtain defatted soymilk from which components such as insoluble protein and dietary fiber remaining floating in the defatted soymilk were removed.

[0107] Next, hydrochloric acid is added thereto to adjust the pH to 4.5, the protein component is subjected to isoelectric precipitation, and the acid-soluble component "whey" is removed by centrifugation to obtain the acid-insoluble component "curd". Water was added so that the curd accounted for 10% of the solids, and neutralized with sodium hydroxide to obtain a neutralized slurry.

[0108] ...

manufacture example 2

[0111] In Production Example 1, the step of centrifuging and removing insoluble components from the defatted soymilk was not required, and the prepared powdery soybean protein material sample B was obtained through the same step.

manufacture example 3

[0113] In the same manner as in Production Example 1, an acid-insoluble component "curd" was prepared.

[0114] Then, water was added so that the solids in the curd accounted for 5%, and it was neutralized with sodium hydroxide to obtain a neutralized slurry.

[0115] Next, the neutralized slurry was heat-treated (140° C., 15 seconds) only once using a VTIS sterilizer, and then spray-dried to obtain a powdery soybean protein material sample C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com