Multi-colored zipper and manufacturing method thereof

A production method and zipper technology, applied in clothing, fasteners, sliding fastener components, etc., can solve the problems of affecting texture and grade, complex process, lack of overall sense of finished products, etc., to achieve good texture, high grade, novel and unique appearance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

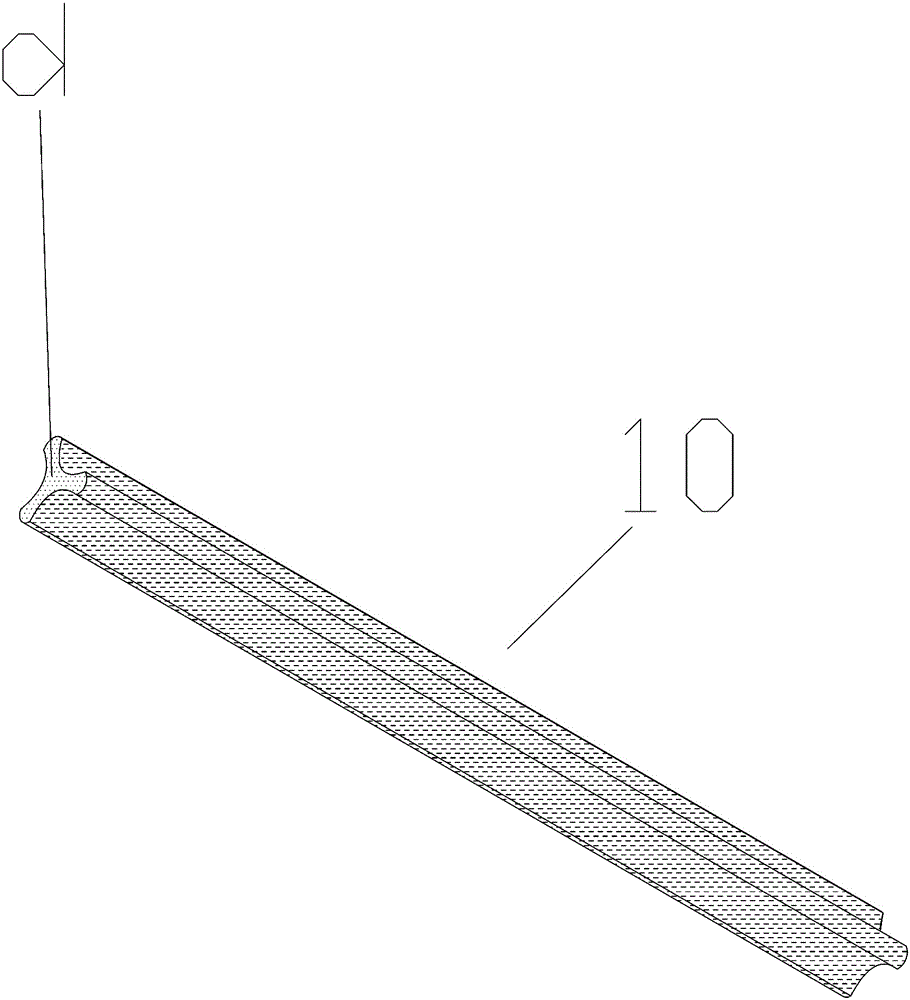

[0028] Embodiment 1, please refer to the multi-color zipper shown in Figure 1-1 to Figure 2-4, the manufacturing steps are as follows:

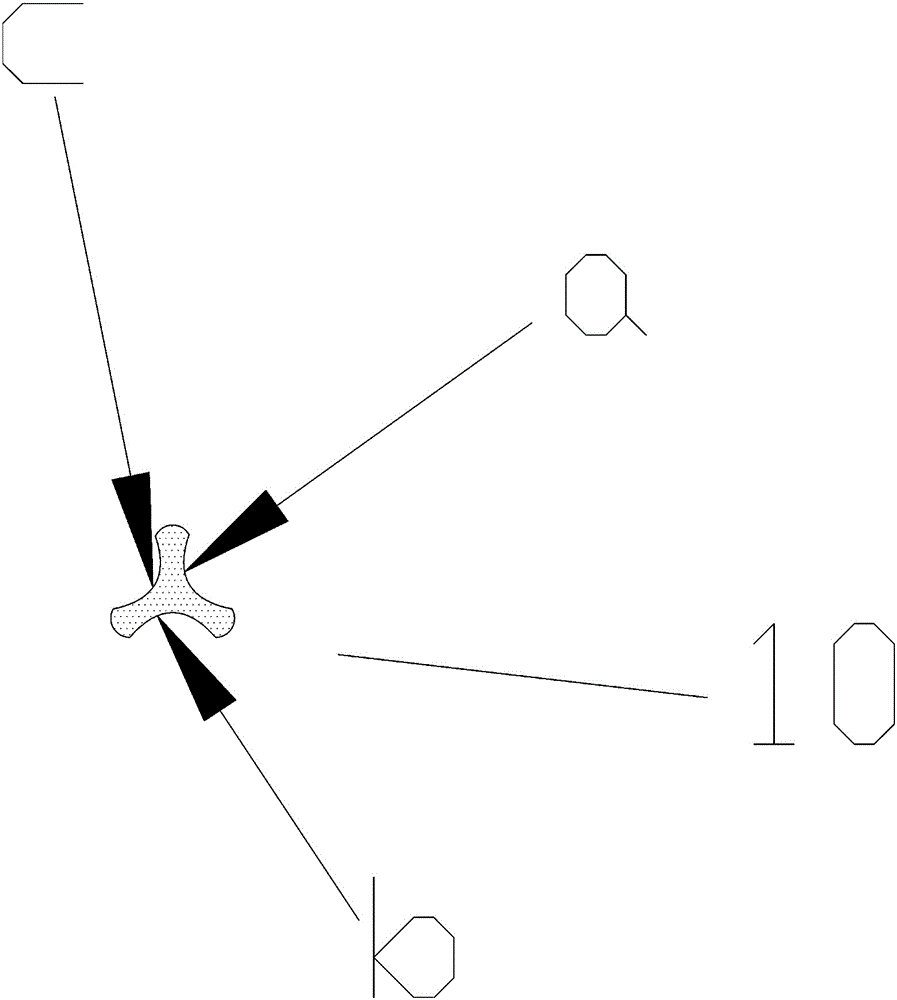

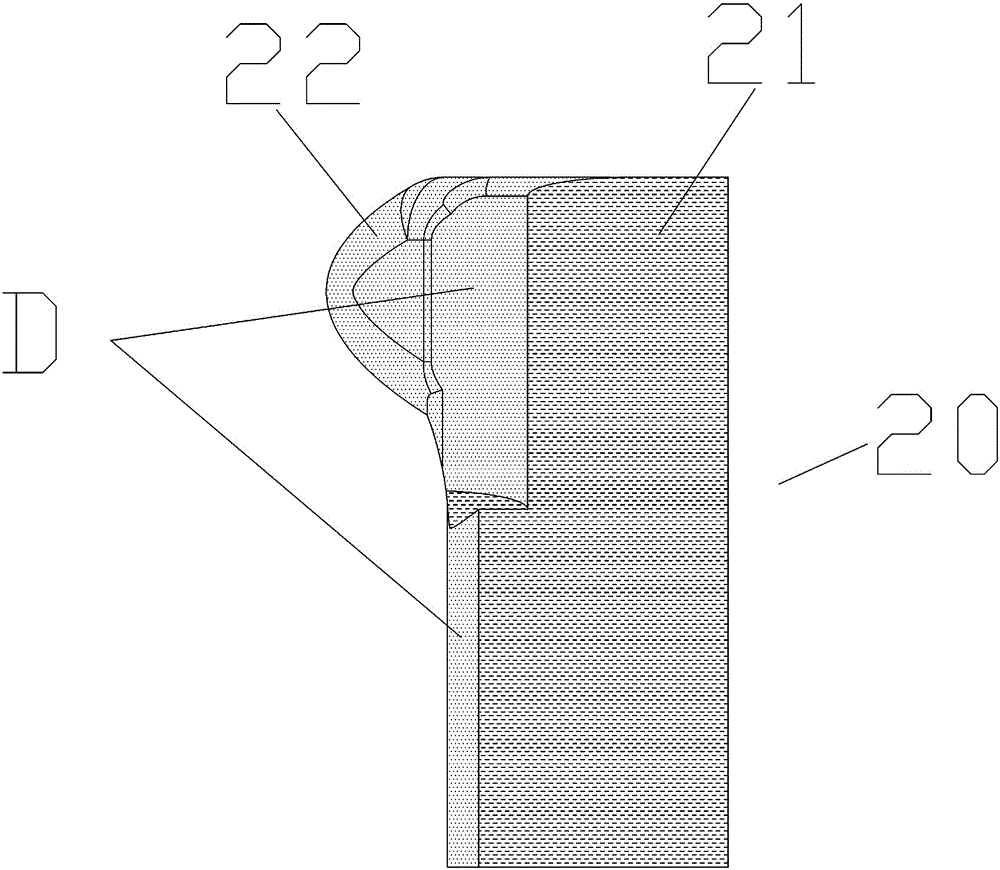

[0029] Step 1: Perform the first coloring treatment on the outer peripheral surfaces a, b, and c of the Y-shaped brass dental floss. Electroplating is used to form the first coloring treatment layer on the dental floss. In this embodiment, the first coloring treatment layer is formed by electroplating gun color process (purchased gun color electroplating liquid, such products are various), that is, on the outer peripheral surface a, A layer of gun color is electroplated on b and c to form gun color on the outer peripheral surfaces a, b and c of the Y-shaped brass dental floss.

[0030] Step 2: The Y-shaped brass dental floss in step 1 is subjected to chaining treatment to form a plurality of chain elements, and the first coloring treatment layer of electroplating gun color is formed on the two side end surfaces A, B and B of the tooth holder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com