Self-adhesive waterproofing coiled material cementing material, its preparation method and waterproofing coiled material prepared from self-adhesive waterproofing coiled material cementing material

A self-adhesive waterproofing membrane and waterproofing membrane technology, applied in the directions of adhesives, adhesive types, asphalt material adhesives, etc., can solve the problems of easy agglomeration, easy to block pipes, etc., and achieve low cost and good waterproof performance. , the effect of excellent low temperature and heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A modified asphalt waterproof membrane with excellent high and low temperature performance, comprising an upper protective film, an upper self-adhesive waterproof membrane binder layer, a base layer, a lower self-adhesive waterproof membrane binder layer and a lower protective film.

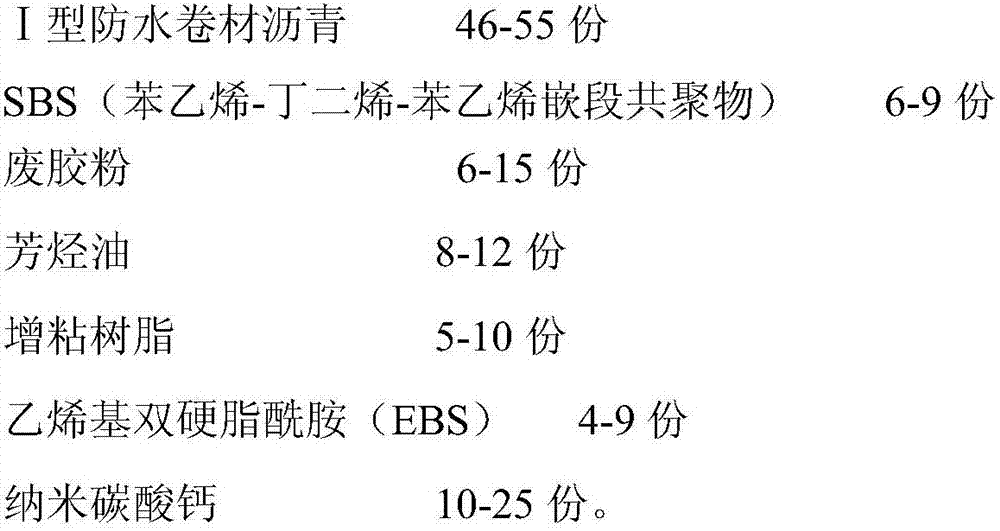

[0023] The preparation method of the upper self-adhesive waterproof membrane binder layer and the lower self-adhesive waterproof membrane binder layer is as follows: First, heat 46 parts of type I waterproof membrane asphalt to 190-200 ° C, add 8 parts of aromatic oil and 4 parts of EBS Stir evenly and cool down to 180-190°C, then add 6 parts of SBS and heat up to 190-200°C, control the temperature, stir for 1.5h, then add 5 parts of tackifying resin (15 parts of coumarone resin, 15 parts of terpene resin, C9 resin (15 parts) and 6 parts of waste rubber powder were stirred at this temperature for 0.5h, and 10 parts of nano-calcium carbonate were added and stirred for 0.5h to obtain the pro...

Embodiment 2

[0026] A modified asphalt waterproof membrane with excellent high and low temperature performance, comprising an upper protective film, an upper self-adhesive waterproof membrane binder layer, a base layer, a lower self-adhesive waterproof membrane binder layer and a lower protective film.

[0027] The preparation method of the upper self-adhesive waterproof membrane binder layer and the lower self-adhesive waterproof membrane binder layer is as follows: first, heat 46 parts of Type I waterproof membrane asphalt to 190-200 ° C, add 12 parts of aromatic oil and 8 parts of EBS Stir evenly and cool down to 180-190°C, then add 8 parts of SBS and heat up to 190-200°C, control the temperature, stir for 1.5h, then add 9 parts of tackifying resin (15 parts of coumarone resin, 15 parts of terpene resin, Carbon nine resin (15 parts) and 6 parts of waste rubber powder were stirred at this temperature for 0.5h, and 17.5 parts of nano-calcium carbonate were added and stirred for 0.5h to ob...

Embodiment 3

[0030] A modified asphalt waterproof membrane with excellent high and low temperature performance, comprising an upper protective film, an upper self-adhesive waterproof membrane binder layer, a base layer, a lower self-adhesive waterproof membrane binder layer and a lower protective film.

[0031] The preparation method of the upper self-adhesive waterproof membrane binder layer and the lower self-adhesive waterproof membrane binder layer is as follows: first, heat 50.5 parts of Type I waterproof membrane asphalt to 190-200 ° C, add 10 parts of aromatic oil and 6.5 parts of EBS Stir evenly and cool down to 180-190°C, then add 7.5 parts of SBS and heat up to 190-200°C, control the temperature, stir for 1.5 hours, then add 7.5 parts of tackifying resin (15 parts of coumarone resin, 15 parts of terpene resin, Carbon nine resin (15 parts) and 10.5 parts of waste rubber powder were stirred at this temperature for 0.5h, and 17.5 parts of nano-calcium carbonate were added and stirre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com