Polypropylene composition for automobile bumper and preparation method thereof

A technology of polypropylene composition and automobile bumper, which is applied in the field of automobile bumper materials, can solve the problems of small shrinkage, high cost, and large deformation, and achieve the effects of good size matching, high dimensional stability, and moderate cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

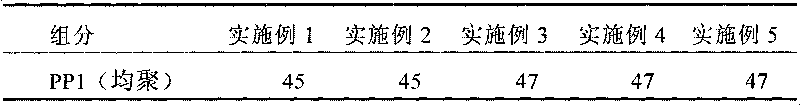

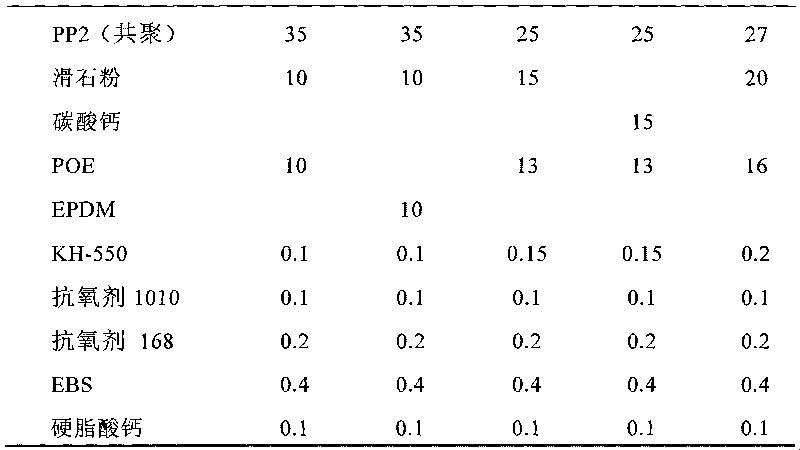

[0023] The materials were weighed according to the components and proportions provided in Table 1, mixed in a high-speed mixer for 15 minutes, and the temperature was controlled at 60-70° C., and then extruded by a twin-screw extruder to obtain a composition. The extrusion temperature of each stage is set at 195°C, 205°C, 215°C, 215°C, 215°C, 215°C, 225°C.

[0024] The test results are shown in Table 2.

[0025] It can be seen from Table 2 that according to the appropriate component distribution ratio and suitable processing technology, automobile bumper materials that meet the needs of various automobile manufacturers can be prepared. In the amount of added talcum powder, there are 10%, 15% , 20% of the distinction, correspondingly, if it is necessary to meet the requirements of the bumper material, it is also necessary to properly adjust the amount of the elastomer, so as to ensure the impact performance of the bumper material.

[0026] In order to ensure the molding and pr...

Embodiment 6~9

[0033] The materials were weighed according to the components and proportions provided in Table 3, mixed in a high-speed mixer for 15 minutes, and the temperature was controlled at 60-70° C., and then extruded by a twin-screw extruder to obtain a composition. The extrusion temperature of each stage is set at 195°C, 205°C, 215°C, 215°C, 15°C, 215°C, 225°C.

[0034] The test results are shown in Table 4.

[0035] The added talcum powder has an impact on the performance of the bumper. Because of its small particle size, the superfine talc powder does not change the chain structure of the resin in the branch matrix very much, so it has an impact on the elongation at break and impact properties of the resin. It is smaller than ordinary talc powder, and because ultrafine talc powder can promote the recrystallization of resin, it has a good effect on improving the rigidity of resin. It is obvious from the test results that we can prepare ultrafine talc powder High-end car bumper. O...

Embodiment 10

[0044] Weigh the materials according to the following weight ratio: polypropylene resin 50%, wollastonite and chopped glass fiber (weight ratio 1: 1) total 25%, toughening agent thermoplastic polyurethane 25%, coupling agent gamma-methacrylic acid propylene Ester silane 0.5%, antioxidant 3001%, lubricant calcium stearate and EBS (weight ratio 1: 3) altogether 1%; Mix 15 minutes in high-speed mixer, temperature is controlled at 60~70 ℃, after that The composition was obtained after extrusion with a twin-screw extruder. The extrusion temperature of each stage is set at 195°C, 205°C, 215°C, 215°C, 15°C, 215°C, 225°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com