Glass fiber-enhanced montmorillonite-modified nylon composite material with low water absorption and high dimensional stability and preparation method thereof

A nylon composite material and dimensional stability technology, which is applied in the field of modified nylon composite materials, can solve problems such as the decline in mechanical properties of dimensional stable materials, restrictions on the application of nylon materials, and high water absorption of nylon materials, achieving high dimensional stability, Effect of high crystallinity and low water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

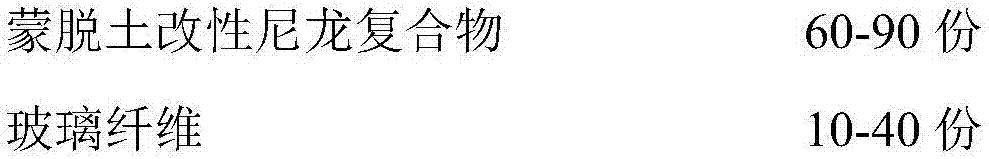

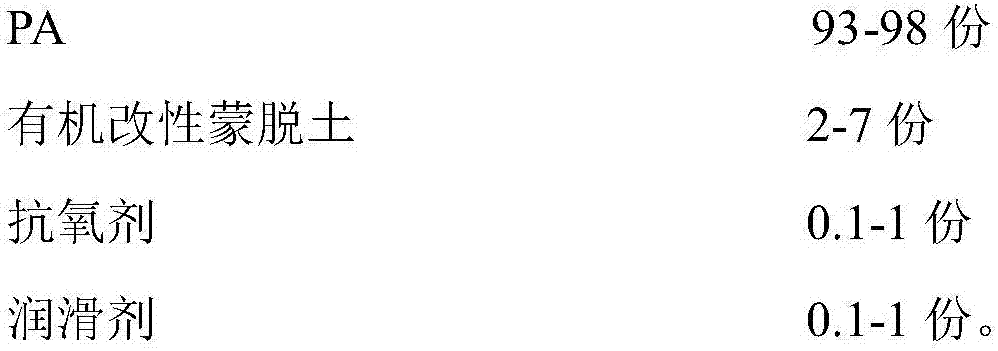

Method used

Image

Examples

Embodiment 1

[0022] Preparation of montmorillonite-modified nylon composite: 95 parts by weight of nylon 6 (vacuum-dried at 100°C for 12 hours), 5 parts by weight of montmorillonite modified by cetyltrimethylammonium bromide, 0.1 part by weight of lubricant After pentaerythritol stearate, 0.05 parts by weight of antioxidant 1098 and 0.05 parts by weight of antioxidant 168 are placed in a high-speed mixer for premixing for 10 minutes, the mixture is added to the main feed port of the twin-screw extruder, and the screw speed is controlled at 450rpm , and the montmorillonite modified nylon compound is obtained after melt extrusion and granulation.

[0023] After 80 parts by weight of the above-mentioned montmorillonite-modified nylon compound, 0.1 part by weight of lubricant pentaerythritol stearate, 0.1 part by weight of antioxidant 1098 and 0.1 part by weight of antioxidant 168 were premixed in a high-speed mixer for 10 minutes, The main material port is added to the twin-screw extruder, an...

Embodiment 2

[0025] Preparation of montmorillonite-modified nylon composite: 98 parts by weight of nylon 6 (dried in vacuum at 100°C for 12 hours), 2 parts by weight of montmorillonite modified by hexadecyltributylphosphorus bromide, 0.5 parts by weight of lubricant Ethylene bis stearamide, 0.25 parts by weight of antioxidant 1098 and 0.25 parts by weight of antioxidant 168 are placed in a high-speed mixer for premixing for 10 minutes, and the main feed port of the mixture is added to the twin-screw extruder, and the screw speed is controlled. 450rpm, the montmorillonite modified nylon compound was obtained after melt extrusion and granulation.

[0026] 70 parts by weight of the above-mentioned montmorillonite-modified nylon compound, 0.15 parts by weight of lubricant ethylene bisstearamide, 0.125 parts by weight of antioxidant 1098 and 0.125 parts by weight of antioxidant 168 were placed in a high-speed mixer and premixed for 10 minutes. , added to the main feed port of the twin-screw ext...

Embodiment 3

[0028] Preparation of montmorillonite-modified nylon composite: 93 parts by weight of nylon 6 (dried in vacuum at 100°C for 12 hours), 7 parts by weight of montmorillonite modified by cetyltrimethylammonium bromide, 1 part by weight of lubricant silicon After the ketone masterbatch, 0.5 parts by weight of antioxidant 1098 and 0.5 parts by weight of antioxidant 168 were placed in a high-speed mixer for premixing for 10 minutes, the mixed material was added to the main material port of the twin-screw extruder, and the screw speed was controlled at 450 rpm. The montmorillonite modified nylon compound is obtained after melt extrusion and granulation.

[0029] Put 60 parts by weight of the above-mentioned montmorillonite-modified nylon compound, 0.2 parts by weight of silicone masterbatch, 0.15 parts by weight of antioxidant 1098 and 0.15 parts by weight of antioxidant 168 in a high-speed mixer for 10 minutes, then add the twin-screw The main feed port of the extruder, then 40 part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com