Injection molding method for soft surface and stitch lines of automotive door interior trimming panel

A technology for injection molding and interior panels, which is applied to household components, household appliances, and other household appliances. It can solve the problems of poor dimensional stability, high defect rate, and high equipment cost, achieving strong dimensional stability, reducing defect rate, The effect of low equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with accompanying drawing:

[0030] The vacuum forming machine adopted in the present invention includes a male mold, a female mold, and vacuum forming equipment. The male mold is provided with tiny holes for vacuuming, and the female mold is provided with tiny holes for vacuuming, and has texture patterns required by customers. (Including sewing thread molding) The vacuum forming machine is divided into two parts, a. skin heating area, which contains heating rods, and the skin heating and drying area; b. vacuum forming area, where vacuum forming molds are placed, and the preforming area. These two areas carry out the drying and warming of the skin through the skin clamping frame and place the skin into the vacuum forming mold.

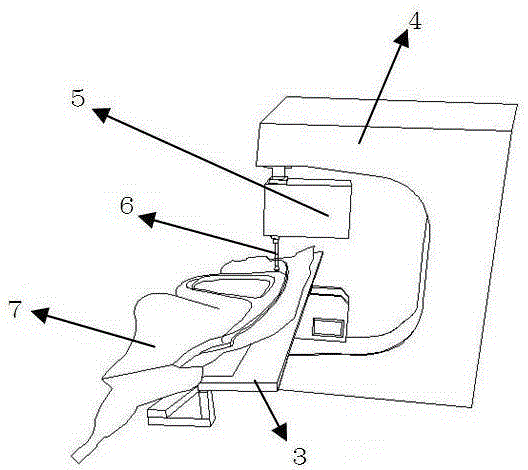

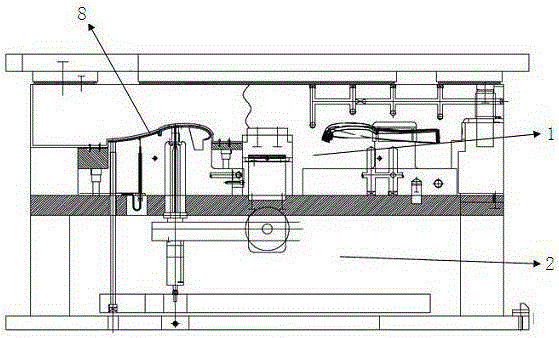

[0031] like figure 1 As shown, the 3D sewing machine used in the present invention includes a fixed seat, a mechanical arm, a sewing machine, a laser scanning head, and an a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com