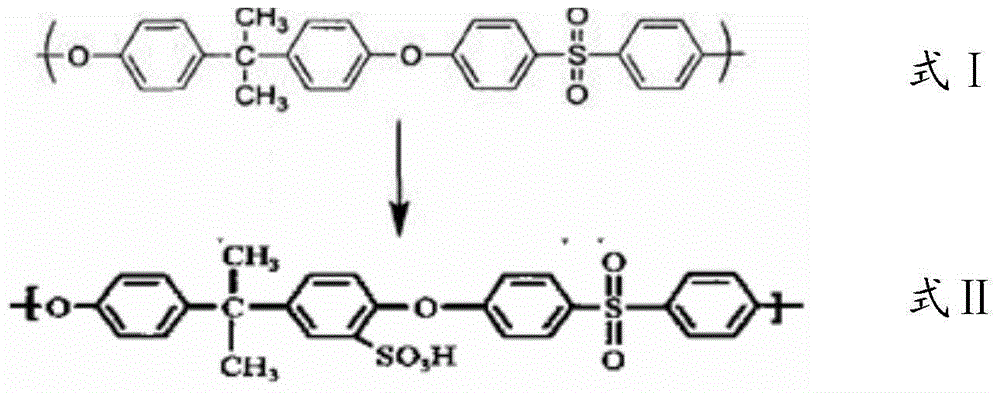

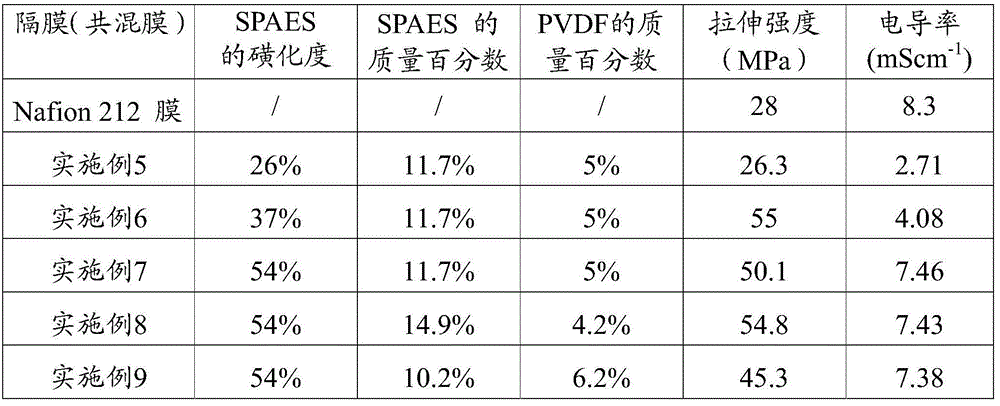

Sulfonated poly (arylene ether sulfone), blend film for all-vanadium flow battery and preparation methods thereof

A technology of sulfonated polyarylethersulfone and all-vanadium redox flow battery, which is applied in the direction of fuel cells, battery pack parts, fuel cell parts, etc., can solve the problems of low mechanical strength, damage, and poor dimensional stability of the membrane. Achieve the effect of low price, strong dimensional stability and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A kind of preparation method of concentrated sulfuric acid sulfonated polyaryl ether sulfone, specifically as follows:

[0035] (1) Slowly add 10mL concentrated sulfuric acid into a 250mL three-neck flask, plug one mouth with a vacuum glass stopper, and adjust the stirrer to control a certain stirring speed for stirring;

[0036] (2) Then weigh 1g of dry polyarylethersulfone PAES powder and slowly add it into a three-necked beaker. Under the condition of electric stirring, at a temperature of 80°C, after sulfonation reaction for 5 hours, stop stirring, and let the reactant stand for a period of time. Sonicate to remove air bubbles. Then pour the sulfonated product into a 500mL separatory funnel and fix it on an iron stand. Use a separatory funnel to control the flow rate of the product, slowly pour it into a large amount of ice water under stirring conditions, the purple-red liquid turns into a white filament, stir it electrically for a certain period of time, and chan...

Embodiment 2

[0044] A kind of preparation method of concentrated sulfuric acid sulfonated polyaryl ether sulfone, specifically as follows:

[0045](1) Slowly add 20mL concentrated sulfuric acid into a 250mL three-necked flask, plug one mouth with a vacuum glass stopper, and adjust the stirrer to control a certain stirring speed for stirring;

[0046] (2) Then weigh 1g of dry PAES powder and slowly add it into a three-necked beaker. Under the condition of electric stirring, at a temperature of 85°C, after sulfonation reaction for 12 hours, stop stirring, let the reactant stand for a period of time, and use ultrasonic treatment to catch up. net air bubbles. Then pour the sulfonated product into a 500mL separatory funnel and fix it on an iron stand. Use a separatory funnel to control the flow rate of the product, slowly pour it into a large amount of ice water under stirring conditions, the purple-red liquid turns into a white filament, stir it electrically for a certain period of time, and ...

Embodiment 3

[0048] A kind of preparation method of concentrated sulfuric acid sulfonated polyaryl ether sulfone, specifically as follows:

[0049] (1) Slowly add 30mL concentrated sulfuric acid into a 250mL three-neck flask, plug one mouth with a vacuum glass stopper, and adjust the stirrer to control a certain stirring speed for stirring;

[0050] (2) Then weigh 1g of dry PAES powder and slowly add it into a three-necked beaker. Under the condition of electric stirring, at a temperature of 90°C, after sulfonation reaction for 25 hours, stop stirring, let the reactant stand for a while, and ultrasonically treat it to catch up. net air bubbles. Then pour the sulfonated product into a 500mL separatory funnel and fix it on an iron stand. Use a separatory funnel to control the flow rate of the product, slowly pour it into a large amount of ice water under stirring conditions, the purple-red liquid turns into a white filament, stir it electrically for a certain period of time, and change the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com