Air insulation ring main unit

An air-insulated ring network cabinet technology, applied in the field of switch cabinets, can solve problems such as the difficulty of recycling solid-sealed pole shells, affecting the use of insulating ring network cabinets, and irreversible insulation performance, and achieves light weight, reduced weight, and low cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

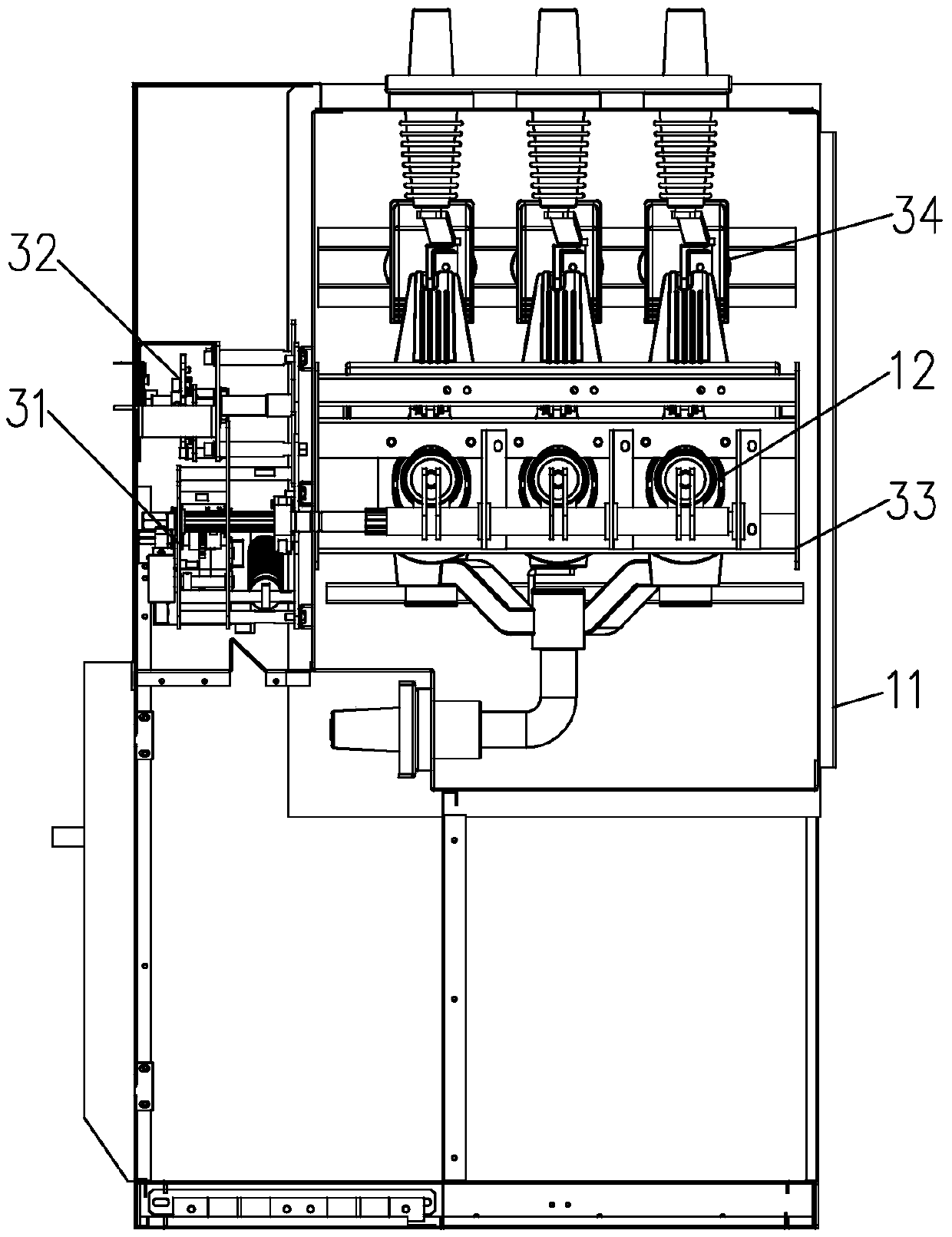

[0012] Such as figure 1 As shown, the air-insulated ring network cabinet of the present invention includes a housing 11 and a circuit breaker body 12 arranged in the housing 11, a circuit breaker operating mechanism 31, an isolation mechanism 32, a circuit breaker body bracket 33, and a static contact insulating support 34, etc., the circuit breaker body 12 includes a solid-sealed pole housing 121, and the solid-sealed pole housing 121 is made of glass fiber reinforced nylon resin.

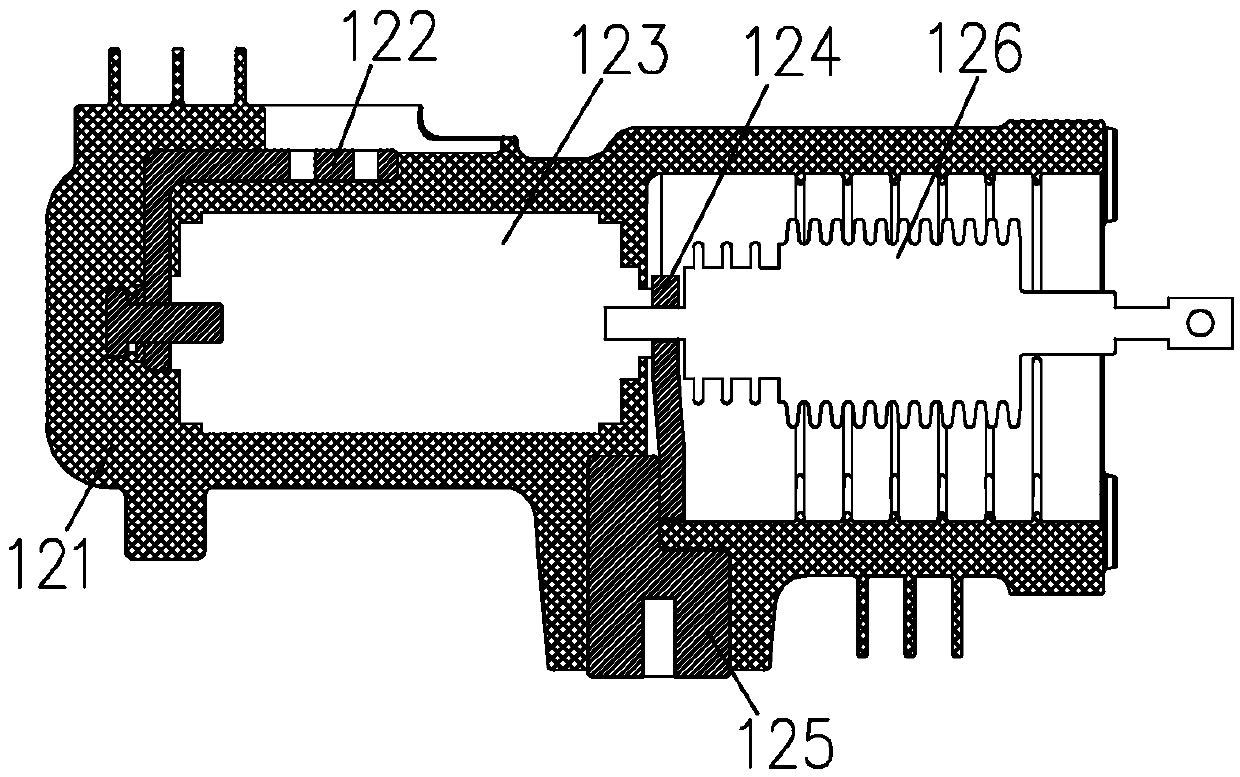

[0013] Such as figure 2 As shown, the circuit breaker body 12 also includes an incoming conductor 122, a vacuum interrupter 123, a flexible connection 124, an outgoing conductor 125, and a breaker pull rod 126. The solid-sealed pole housing 121 is made of glass fiber reinforced nylon resin. During the pouring process, the incoming conductor 122, the vacuum interrupter 123, and the outgoing conductor 125 are embedded and poured together. The soft connection 124 and the circuit breaker pull rod 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com