Forming device and forming method of continuous fiber reinforced thermoplastic resin preimpregnation sheet material

A technology for reinforcing thermoplastic and continuous fibers, applied in the field of continuous fiber reinforced thermoplastic resin composite materials, can solve the problems of poor fiber impregnation effect, large melt resistance, affecting pultrusion stability, etc., to improve impregnation effect, shorten mold length, The effect of not easy to break the wire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

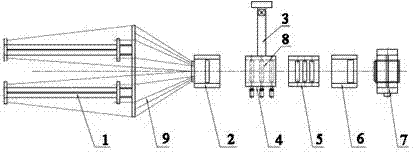

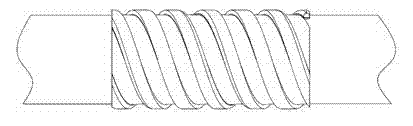

[0025] According to the molding equipment of continuous fiber reinforced thermoplastic resin prepreg sheet of the present invention, along the extrusion direction, it comprises: creel 1, fiber pre-dispersion device 2, single screw extruder 3, spiral melt impregnation mold 4, secondary Rolling device 5, cooling tractor 6 and winder 7; spiral melt impregnation die 4 is connected at right angles to single screw extruder 3, fiber pre-dispersion device 2 is arranged between creel and spiral melt impregnation die 4 Between, followed by cooling tractor 6 and winding machine 7 in sequence; a spiral impregnation roller 8 is arranged in the spiral melt impregnation mold 4, and the outer surface of the spiral impregnation roller 8 begins to have spiral grooves, and is driven by a motor on the spiral Rotate inside the type melt impregnation mold 4.

[0026] Spiral impregnation roller 8 has a diameter of 60mm, a pitch of 120mm, a spiral groove depth of 3mm, a groove width of 8mm, a pitch o...

Embodiment 2

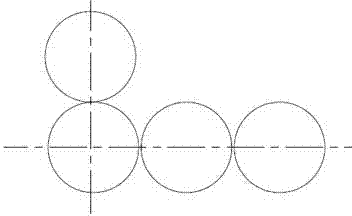

[0035] According to the molding equipment of continuous fiber reinforced thermoplastic resin prepreg sheet of the present invention, along the extrusion direction, it comprises: creel 1, fiber pre-dispersion device 2, single screw extruder 3, spiral melt impregnation mold 4, secondary Rolling device 5, cooling tractor 6 and winder 7; spiral melt impregnation die 4 is connected at right angles to single screw extruder 3, fiber pre-dispersion device 2 is arranged between creel and spiral melt impregnation die 4 Between, followed by cooling tractor 6 and winder 7 in turn; three spiral impregnation rollers 8 are arranged in the spiral melt impregnation mold 4, and the outer surface of the spiral impregnation roller 8 begins to have spiral grooves, and is driven by a motor on the spiral Rotate inside the type melt impregnation mold 4.

[0036] Spiral dipping roller 8 has a diameter of 100mm, a pitch of 200mm, a spiral groove depth of 3mm, a groove width of 8mm, a pitch of 100mm, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com