Preparation method of bismuth oxide halide-titanium oxide nanotube array composite photo-catalytic membrane

A technology of titanium oxide nanotubes and composite photocatalysis, applied in the field of photocatalysis, can solve the problems of low activity, easy agglomeration, difficult recycling, etc., achieve good photocatalytic performance, reduce interfacial tension, and facilitate wetting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

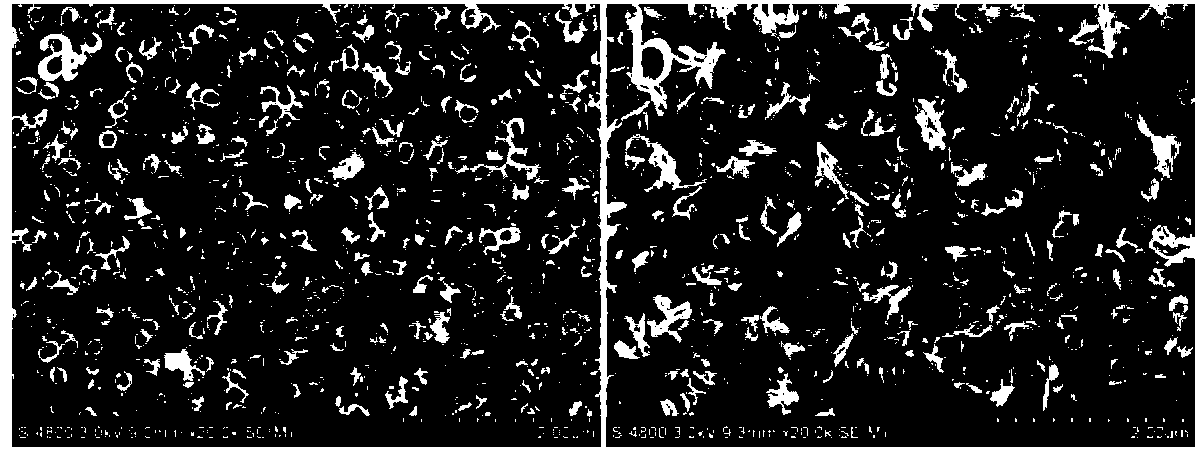

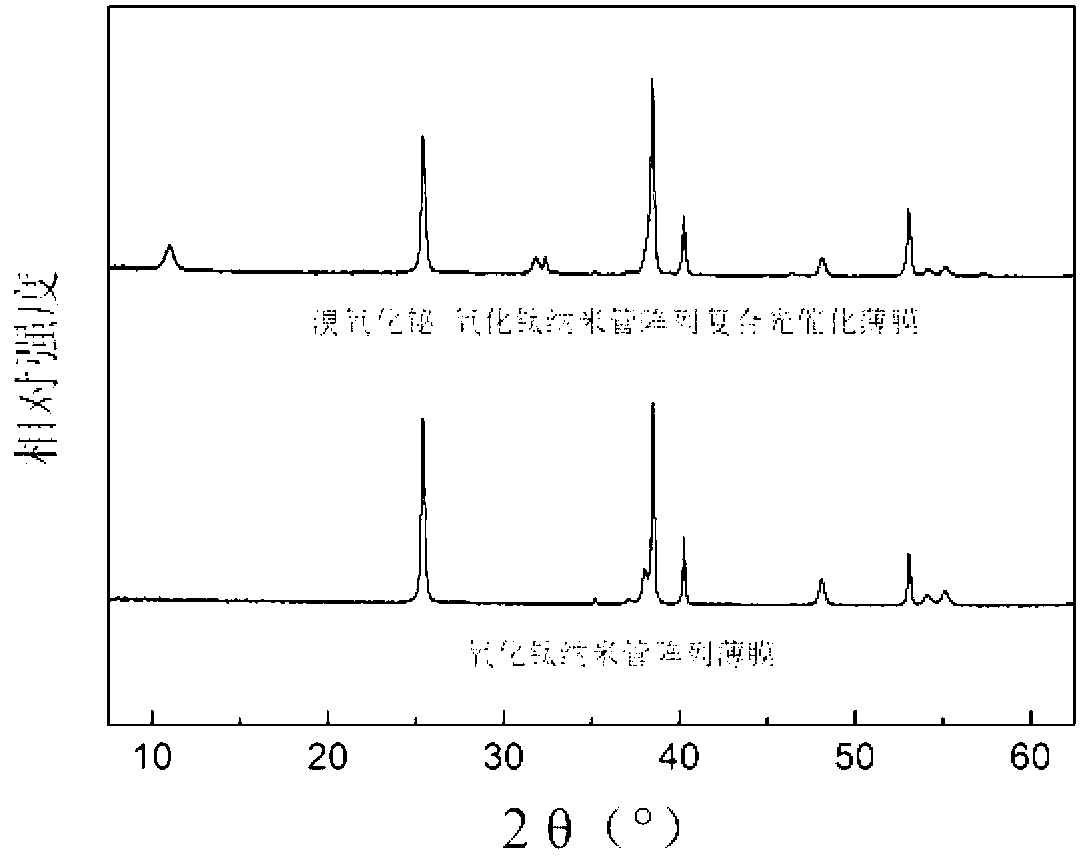

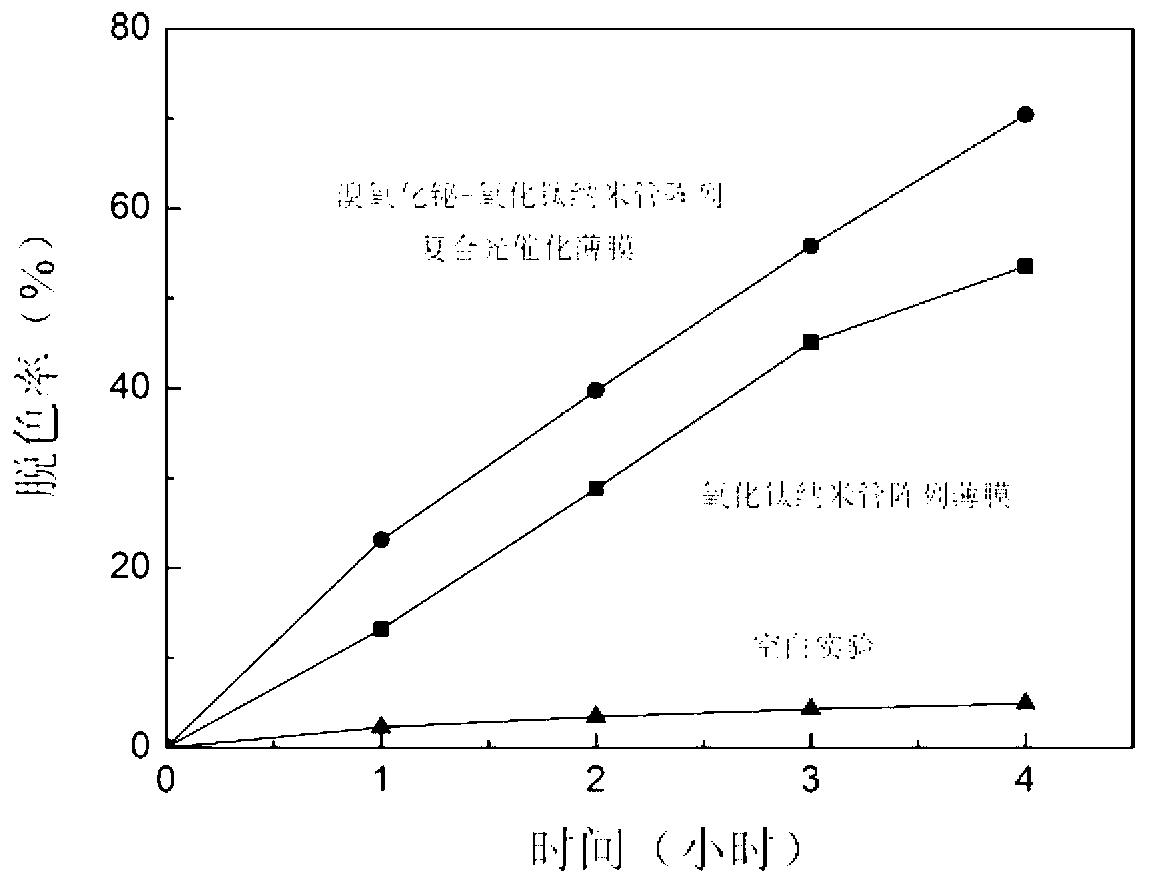

[0027] (1) Preparation of TiO nanotube array film

[0028] Mix ethylene glycol and deionized water at a mass ratio of 4:1, and use the mixed solvent to prepare a 0.25% ammonium fluoride solution. Add the ammonium fluoride solution into the reaction vessel, use the titanium sheet (99.9%) as the anode, and the platinum sheet (99.99%) as the cathode, and anodize at 40°C and 40V for 3 hours, and magnetic stirring is always carried out during the oxidation process. After the reaction, the oxidized titanium sheet, that is, the sample sheet, was washed with deionized water, dried, and annealed at 460° C. for 2 hours to obtain a titanium oxide nanotube array film.

[0029] (2) BiOBr-TiO 2 Preparation of Nanotube Array Composite Photocatalytic Thin Film

[0030] Use 40% acetic acid aqueous solution to prepare 0.5M bismuth nitrate solution, use 0.25M ammonium acetate aqueous solution to prepare 0.25M NH 4 Br solution. Put the annealed sample into a 100ml flask, add 25ml of 0.5M bism...

Embodiment 2

[0034] A titanium dioxide nanotube array film was prepared according to the steps of Example 1 (1).

[0035] Use 50% acetic acid aqueous solution to prepare 0.5M bismuth nitrate solution, and use 0.25M ammonium acetate aqueous solution to prepare 0.3M NH 4 Br solution. Put the annealed sample into a 100ml flask, add 25ml of 0.5M bismuth nitrate solution into the flask, fully immerse the sample under the liquid surface, and vacuum-impregnate it for 60min under reduced pressure to below 10kPa. Then the sample piece was taken out from the bismuth nitrate solution, immersed in 50ml, 0.3M NH 4 Br solution, standing at room temperature for 5h. Finally, send the samples from NH 4 Br solution was taken out, fully washed with deionized water, and dried at 110 °C for 1 h to obtain BiOBr-TiO 2 Nanotube array composite photocatalytic film.

Embodiment 3

[0037] A titanium dioxide nanotube array film was prepared according to the steps of Example 1 (1).

[0038] Use 45% acetic acid aqueous solution to prepare 0.2M bismuth nitrate solution, and use 0.25M ammonium acetate aqueous solution to prepare 0.3M NH 4 Br solution. Put the annealed sample into a 100ml flask, add 25ml of 0.2M bismuth nitrate solution into the flask, fully immerse the sample under the liquid surface, and vacuum-impregnate it for 60min under reduced pressure to below 10kPa. Then the sample piece was taken out from the bismuth nitrate solution, immersed in 50ml, 0.3M NH 4 Br solution, standing at room temperature for 5h. Finally, send the samples from NH 4Br solution was taken out, fully washed with deionized water, and dried at 110 °C for 1 h to obtain BiOBr-TiO 2 Nanotube array composite photocatalytic film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com