In-situ growth SiC nanowire enhanced C/SiC composite material and preparation method thereof

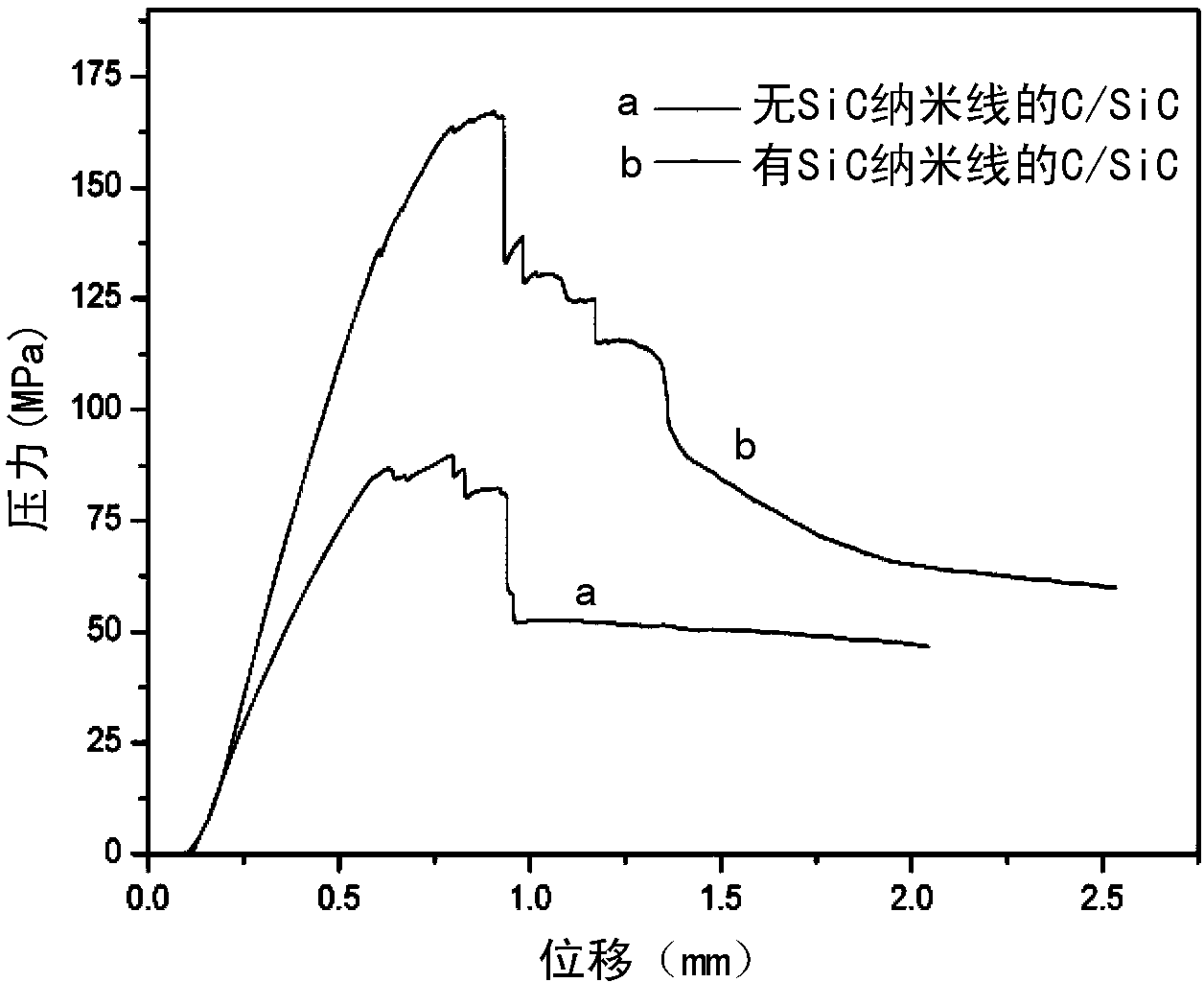

A composite material and in-situ growth technology, which is applied in the field of ceramic matrix composite materials, can solve the problems of insufficient impregnation of carbon fiber fabrics, uneven distribution of SiC nanowires, and low density of composite materials, and achieve uniform size and distribution, and bending strength The effect of lifting and improving the bending mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] 1. Dissolve 50 grams of polycarbosilane in 100 milliliters of solvent gasoline, then add 0.28 grams of reduced iron powder and 180 grams of silicon carbide grinding balls. The mixture was ball milled in a planetary ball mill for 2 hours at room temperature to obtain the desired slurry;

[0052] 2. Immerse a 60×60×12mm C fiber preform into the slurry, place it in a vacuum impregnation tank, evacuate to minus 0.1MPa and keep the pressure for 1 hour, then pressurize to 2MPa and maintain it for 2 hours , and then put the impregnated C fiber preform in the air for cross-linking and curing for more than 6 hours;

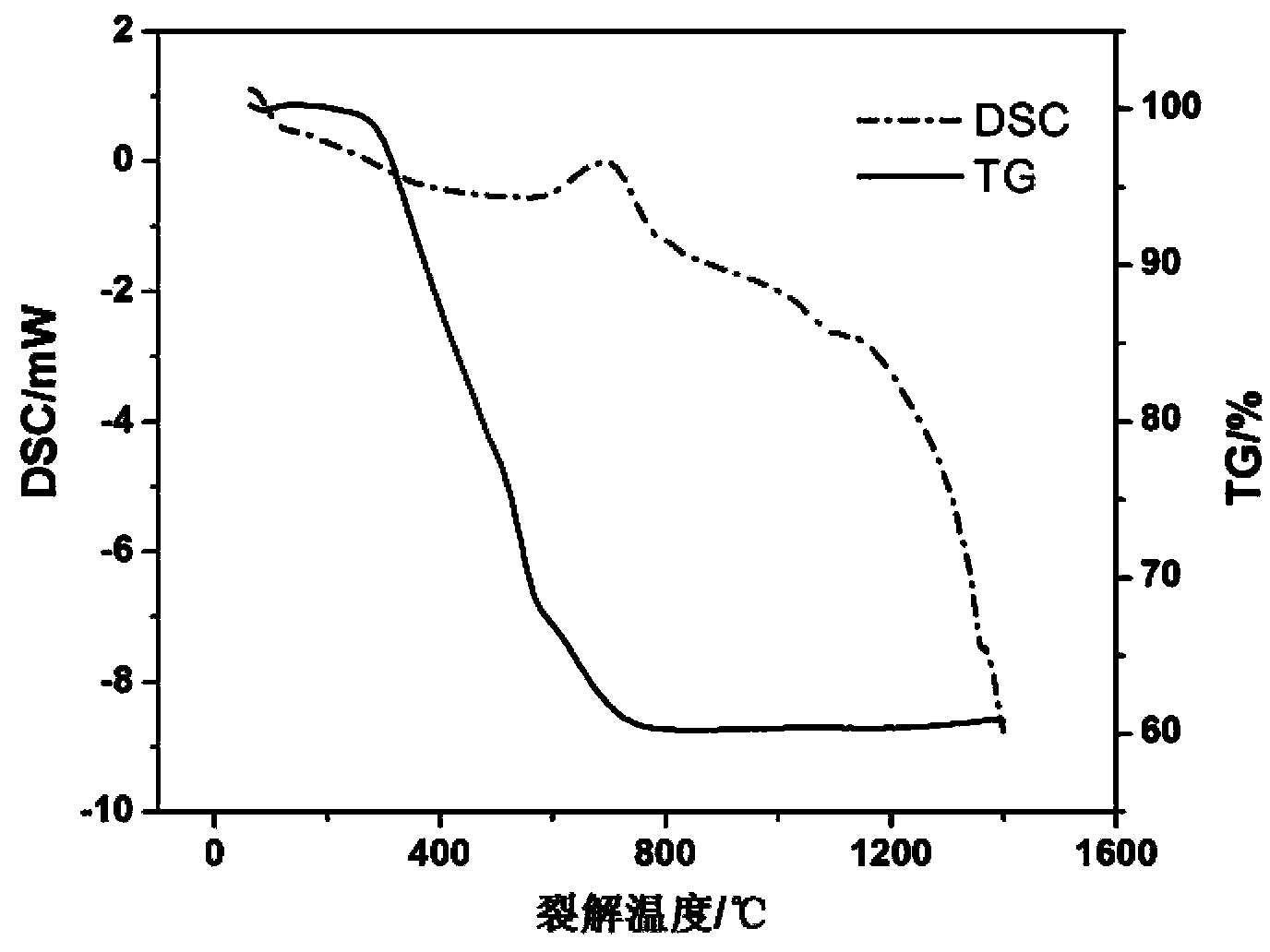

[0053] 3. Put the cross-linked and solidified preform in a multi-functional high-temperature furnace, raise the temperature to 1300°C at a heating rate of 5°C / min, and keep warm at 400°C, 800°C and 1300°C for 2 hours, and cool naturally after reaction To room temperature, obtain the C fiber prefabricated body of growing SiC nanowire in situ;

[0054] 4. Immerse th...

Embodiment 2

[0056] 1. Dissolve 50 grams of polycarbosilane in 100 ml of solvent gasoline, then add 0.294 grams of 200-mesh nickel powder, and add 180 grams of silicon carbide grinding balls. The mixture was ball milled in a planetary ball mill for 2 hours at room temperature to obtain the desired slurry;

[0057] 2. Immerse a 60×60×12mm C fiber preform into the slurry, place it in a vacuum impregnation tank, evacuate to minus 0.1MPa and keep the pressure for 1 hour, then pressurize to 2MPa and maintain it for 2 hours , and then put the impregnated C fiber preform in the air for cross-linking and curing for more than 6 hours;

[0058] 3. Put the cross-linked and solidified preform in a multi-functional high-temperature furnace, raise the temperature to 1300°C at a heating rate of 5°C / min, and keep warm at 400°C, 800°C and 1300°C for 2 hours, and cool naturally after reaction To room temperature, obtain the C fiber prefabricated body of growing SiC nanowire in situ;

[0059] 4. Immerse th...

Embodiment 3

[0061] 1. Dissolve 50 grams of polycarbosilane in 100 ml of solvent gasoline, then add 0.588 grams of 200-mesh nickel powder and 0.56 grams of reduced iron powder, and add 180 grams of silicon carbide grinding balls. The mixture was ball milled in a planetary ball mill for 2 hours at room temperature to obtain the desired slurry;

[0062] 2. Immerse a 60×60×12mm C fiber preform into the slurry, place it in a vacuum impregnation tank, evacuate to minus 0.1MPa and keep the pressure for 1 hour, then pressurize to 2MPa and maintain it for 2 hours , and then put the impregnated C fiber preform in the air for cross-linking and curing for more than 6 hours;

[0063] 3. Put the cross-linked and solidified preform in a multi-functional high-temperature furnace, raise the temperature to 1300°C at a heating rate of 5°C / min, and keep warm at 400°C, 800°C and 1300°C for 2 hours, and cool naturally after reaction To room temperature, obtain the C fiber prefabricated body of growing SiC nan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com