Fiber packing preparation method

A packing and fiber technology, applied in the field of packing preparation, can solve the problems of increasing leakage, wear of pump shaft, damage of sealing surface, etc., and achieve the effects of improving lubrication, improving service life and improving compactness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

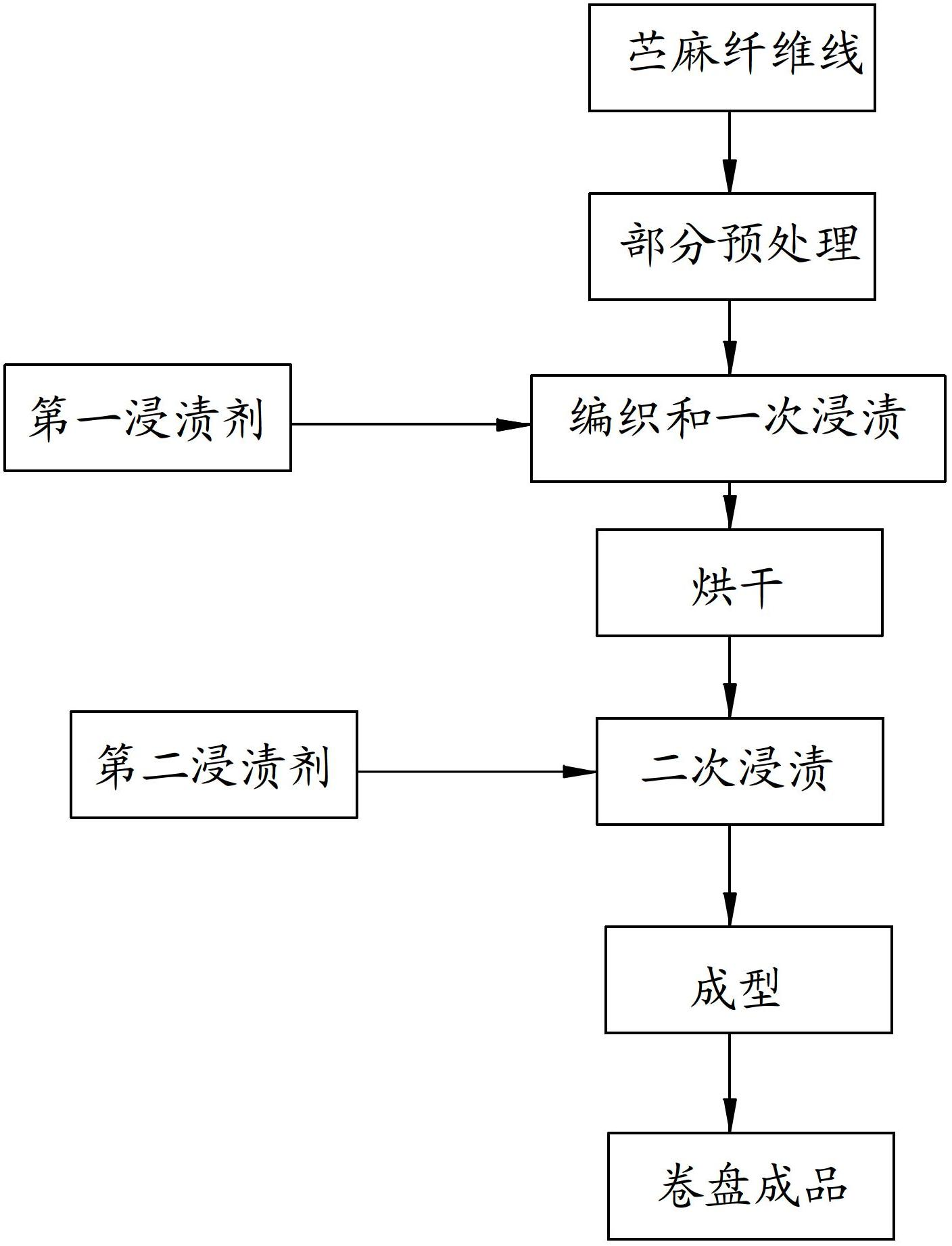

[0027] Example 1, such as figure 1 Shown, the preparation method of the ramie packing in the present embodiment may further comprise the steps:

[0028] ① The ramie fiber thread is impregnated on the first impregnating agent while weaving on the weaving machine, so that the weight of the fiber thread is increased by 35%;

[0029] ②Take it out after dipping, and bake it in an oven at 100°C for 4~6 hours;

[0030] ③Then impregnate twice with the second impregnating agent in the impregnating tank, and the impregnating time is 15 minutes;

[0031] ④Finally, forming, reel finished product,

[0032] The first impregnating agent comprises the following components and their percentages by weight: polytetrafluoroethylene 80%, mineral powder 15%, anti-emulsifier 1%, preservative 1%, water 3%, and the second impregnating agent comprises the following components and its Percentage by weight: paraffin oil 50%, vaseline 50%.

[0033] Before weaving, the fiber yarns accounted for 50% by ...

Embodiment 2

[0041] Embodiment 2, the preparation method of the flax packing in the present embodiment, comprises the steps:

[0042] ① The flax fiber thread is impregnated in the first impregnating agent while weaving on the weaving machine, so that the weight of the fiber thread is increased by 30%;

[0043] ②Take it out after dipping, and bake it in an oven at 110°C for 4~6 hours;

[0044] ③Then impregnate twice with the second impregnating agent in the impregnation tank, and the impregnation time is 20 minutes;

[0045] ④Finally, molding, reel,

[0046] The first impregnating agent comprises the following components and their percentages by weight: polytetrafluoroethylene 75%, mineral powder 19%, anti-emulsifier 1.5%, preservative 1.1%, water 3.4%, and the second impregnating agent comprises the following components and its Percentage by weight: paraffin oil 60%, vaseline 40%.

[0047] Before weaving, the fiber yarns accounted for 30% by weight of the fiber yarns were soaked in the ...

Embodiment 3

[0049] Embodiment 3, the preparation method of the cotton yarn packing in the present embodiment, comprises the steps:

[0050] ① The cotton yarn fiber thread is impregnated on the first impregnating agent while weaving on the knitting machine, so that the fiber thread is increased by 40%;

[0051] ②Take it out after dipping, and bake it in an oven at 90°C for 4~6 hours;

[0052] ③Then impregnate twice with the second impregnating agent in the impregnation tank, and the impregnation time is 10 minutes;

[0053] ④Finally, molding, reel,

[0054] The first impregnating agent comprises the following components and their percentages by weight: polytetrafluoroethylene 85%, mineral powder 11%, anti-emulsifier 0.5%, preservative 0.9%, water 2.6%, and the second impregnating agent comprises the following components and its Percentage by weight: paraffin oil 40%, vaseline 60%.

[0055] Before weaving, the fiber yarns accounted for 70% by weight of the fiber yarns were soaked in the se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Weight | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com