Grid type reinforcing structure

A technology of strengthening structure and grid, applied in wind turbine components, wind energy power generation, sustainable manufacturing/processing, etc., can solve the problem of insufficient rigidity of shell plates, no structural design of nacelle cover, inability to meet rigidity, dimensional accuracy, quality Consistency etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

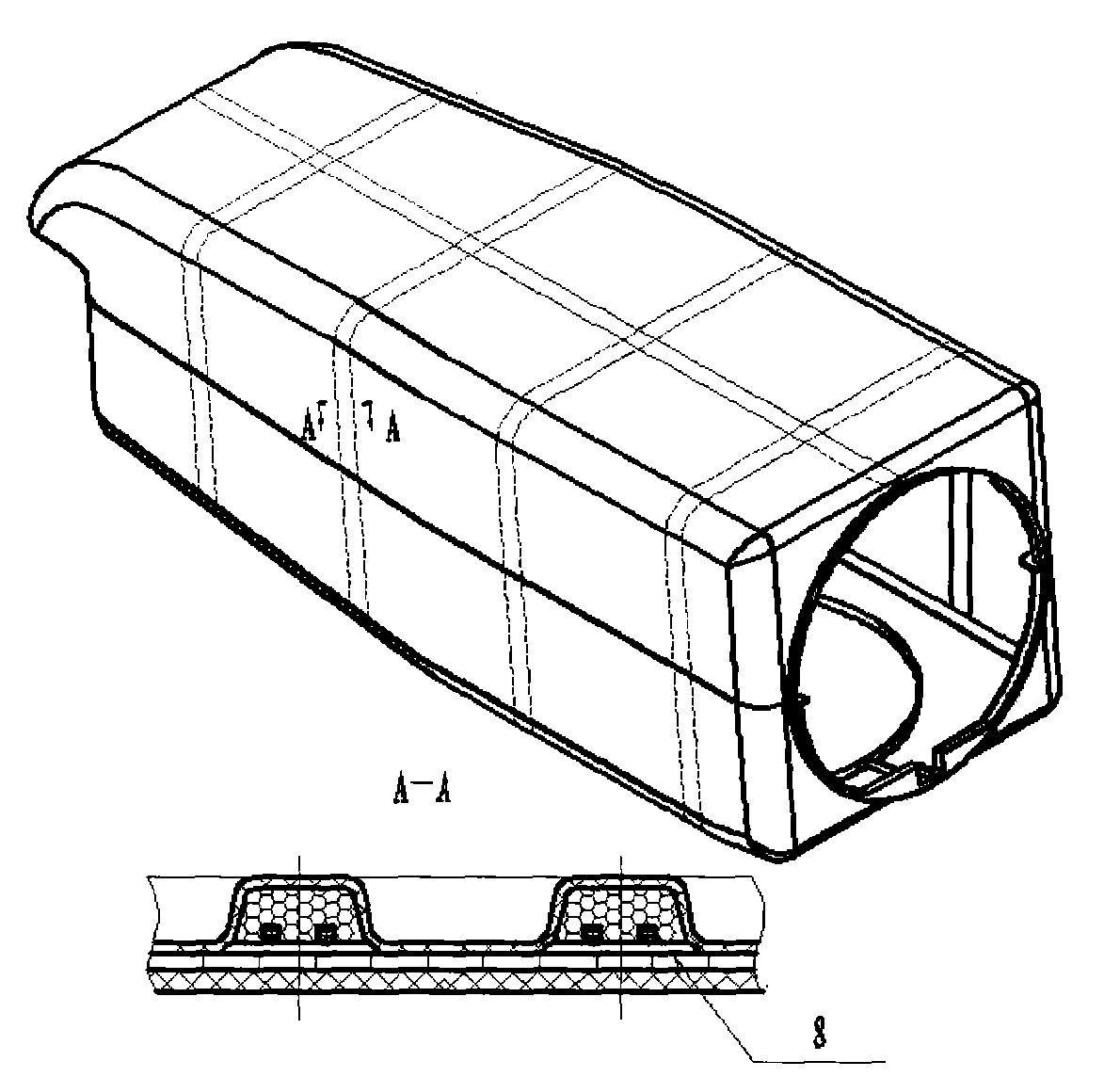

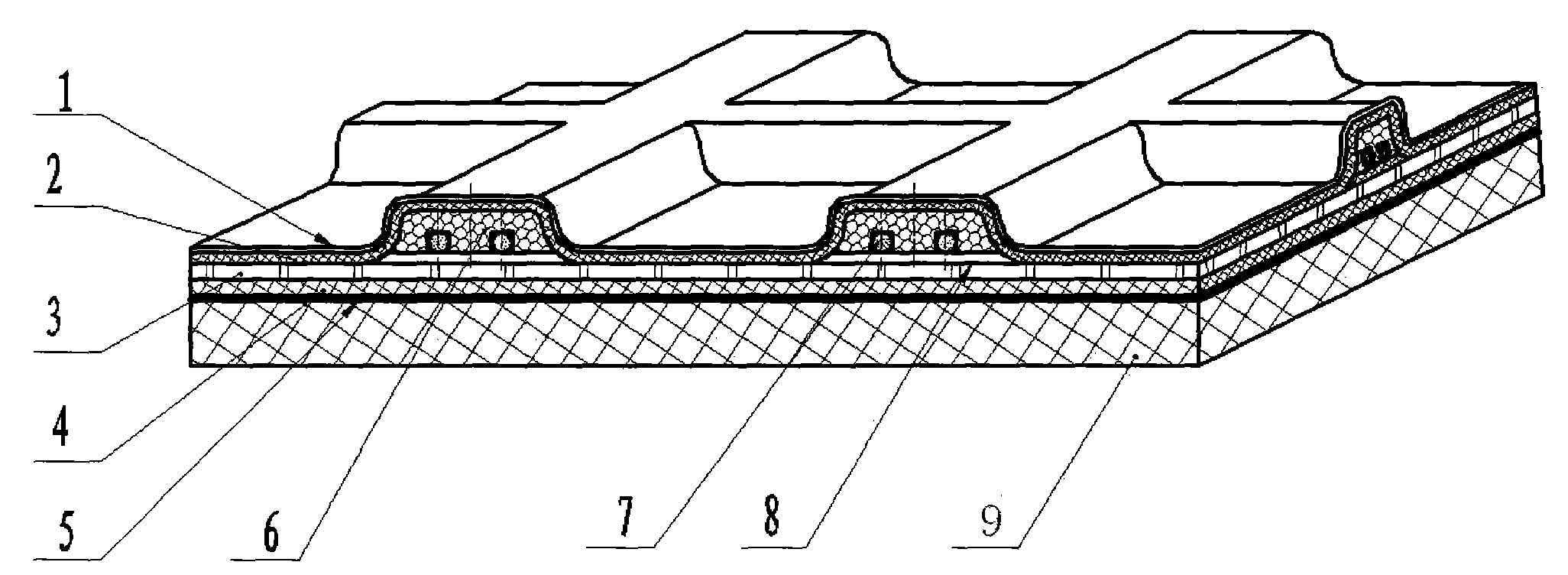

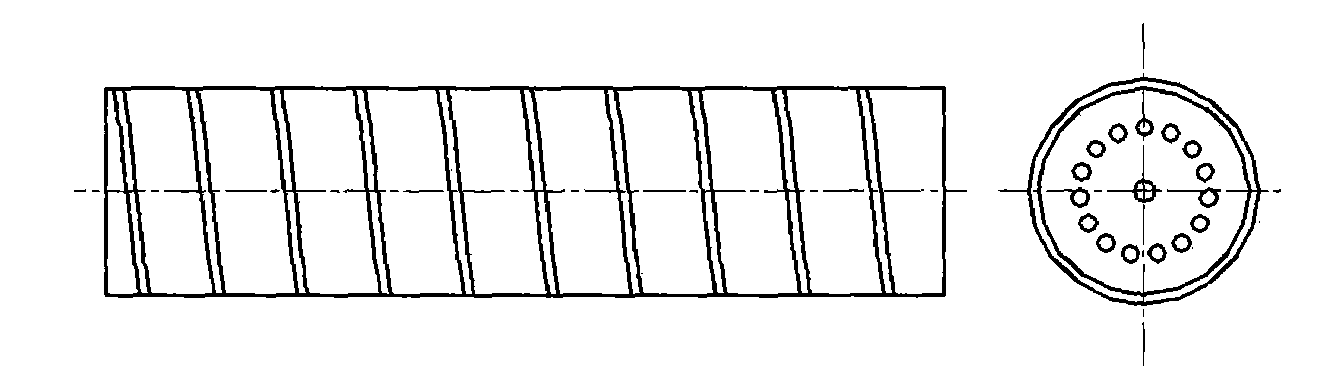

[0025] The present invention is described in detail below with the grid type reinforced structure of the nacelle cover of a certain type of 1.5MW wind generating set as an example, as Figure 1~5shown. This embodiment adopts a three-lobe split design and a grid-type reinforcement structure. The reinforced structure includes a transparent silicone film 1 , an inner panel 2 , a lightweight sandwich layer 3 , an outer panel 4 , a surface coating 5 , a rib inner core 6 , a cross connection block 10 , a resin conduit 7 and a guide strip 8 . The material of the outer plate 4 of the cabin cover plate is glass fiber reinforced plastics with a thickness of 4mm, and a layer of polyester strong-core blanket light-weight sandwich layer 3 with a thickness of 4mm is laid on it. A layer of grid-shaped diversion belt 8 with high permeability ribbon-shaped fabric composed of fiber mesh on the outside and longitudinal glass fiber bundles on the inside is laid on the top of the diversion belt 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com