Catalyst loading CoCr(Mn/Al)FeNi high-entropy alloy nano particles and preparation method and application of catalyst

A technology of nanoparticles and high-entropy alloys, which is applied in the direction of catalyst activation/preparation, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc., can solve problems such as existing limitations, and achieve simple operation, Reduce costs and avoid the effects of reprocessing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] A kind of preparation method of the nano particle catalyst of supporting CoCr(Mn / Al)FeNi high entropy alloy of the present invention, comprises the following steps:

[0037] Step 1, first take the substrate, wash it repeatedly with deionized water by ultrasonic vibration, filter and dry at 45-55°C for 12-24 hours to obtain a spare substrate;

[0038] Step 2, prepare CoCr(Mn / Al)FeNi high-entropy alloy nanoparticles by impregnation method, take metal nitrate precursors, including Co(NO 3 ) 2 ·6H 2 O, CrN 3 o 9 9H 2 O, MnN 2 o 6 4H 2 O or Al(NO 3 ) 3 9H 2 O, FeN 3 o 9 9H 2 O and Ni(NO 3 ) 2 ·6H 2 O, and add ethanol solution to dissolve it, obtain precursor solution;

[0039] Step 3, immerse the spare substrate obtained in step 1 in the precursor solution obtained in step 2 for 4 to 8 hours, and use a rotary evaporator to vacuum distill off excess ethanol solution solution, the conditions are: heating to a temperature of 40 to 50 °C in a water bath, and the...

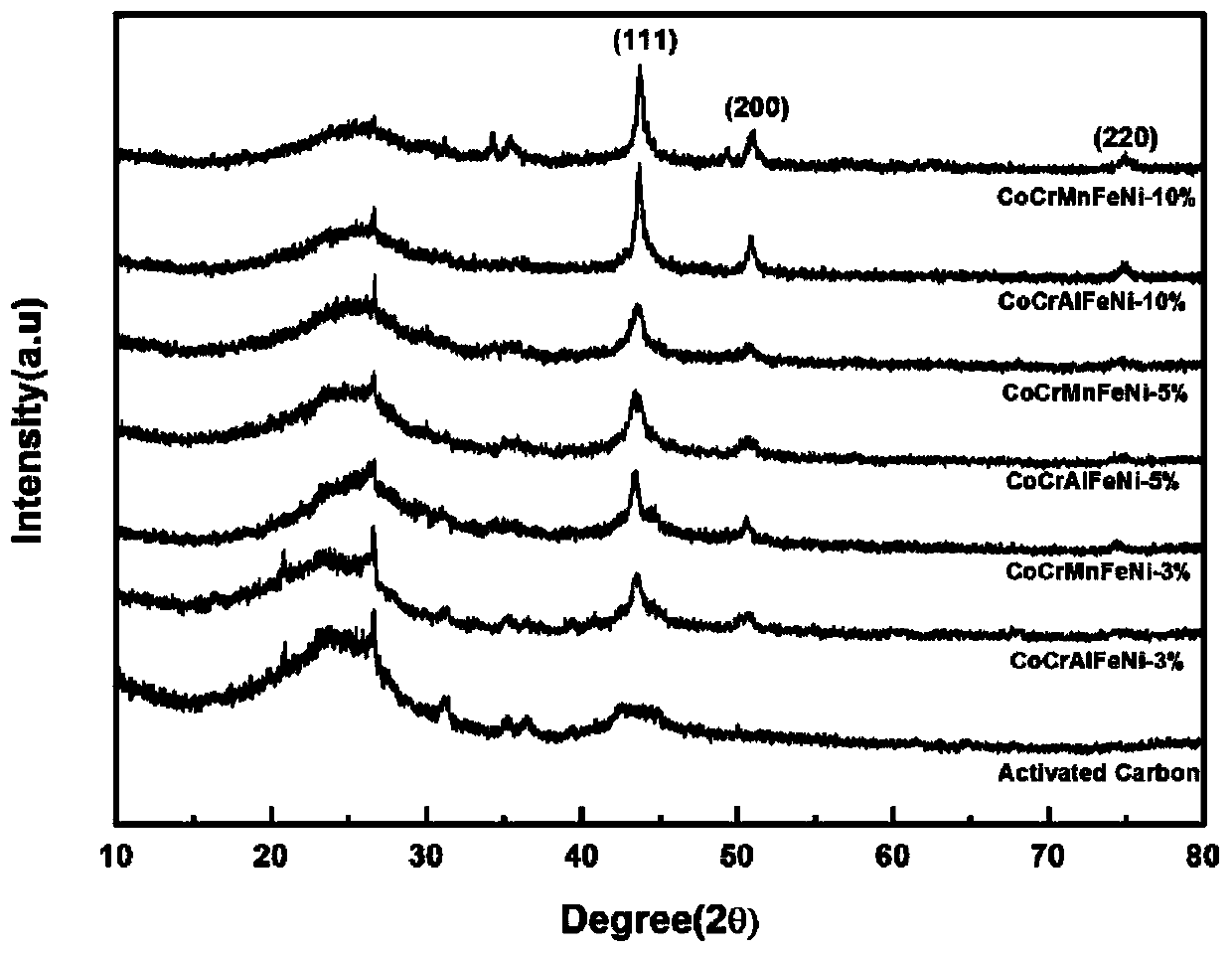

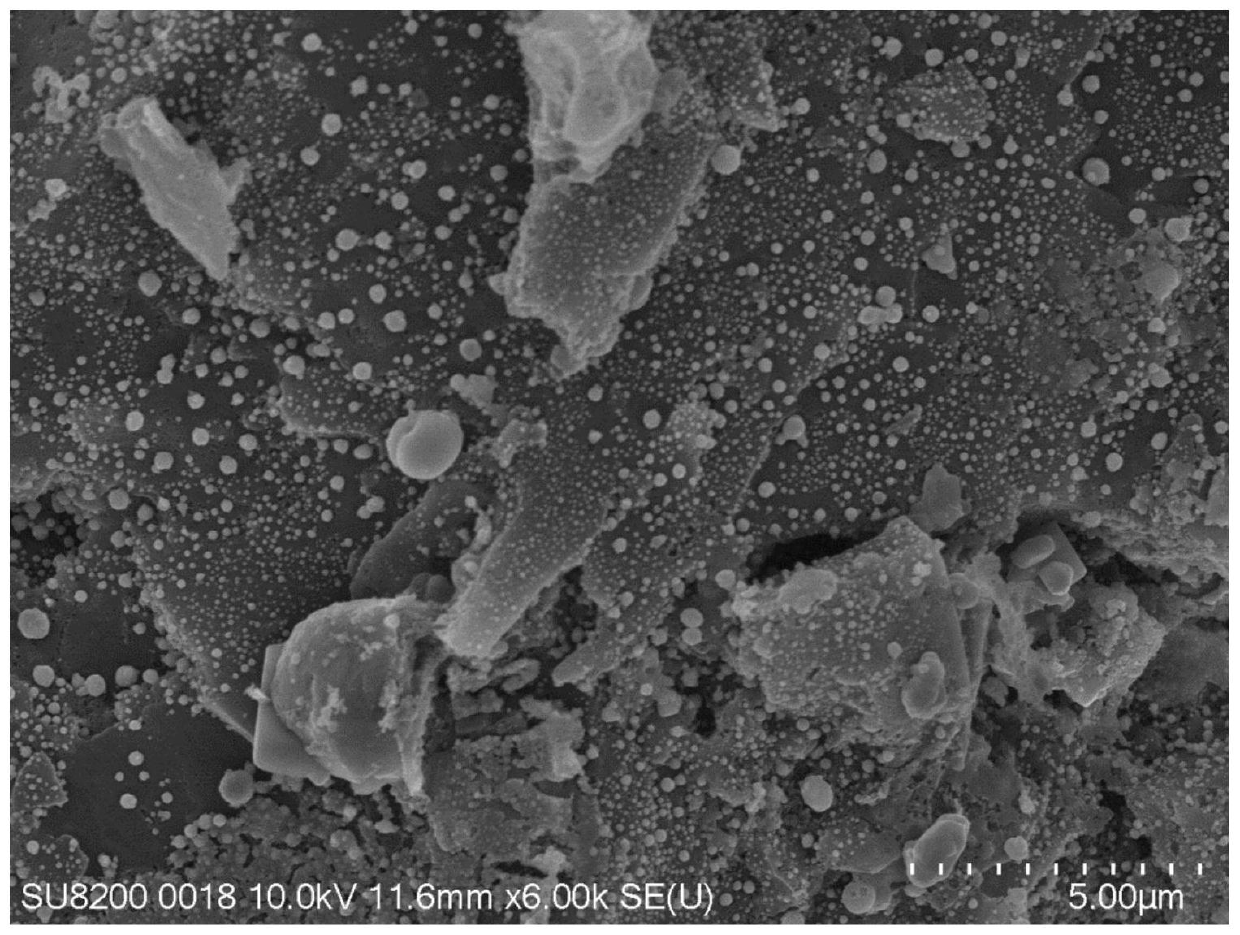

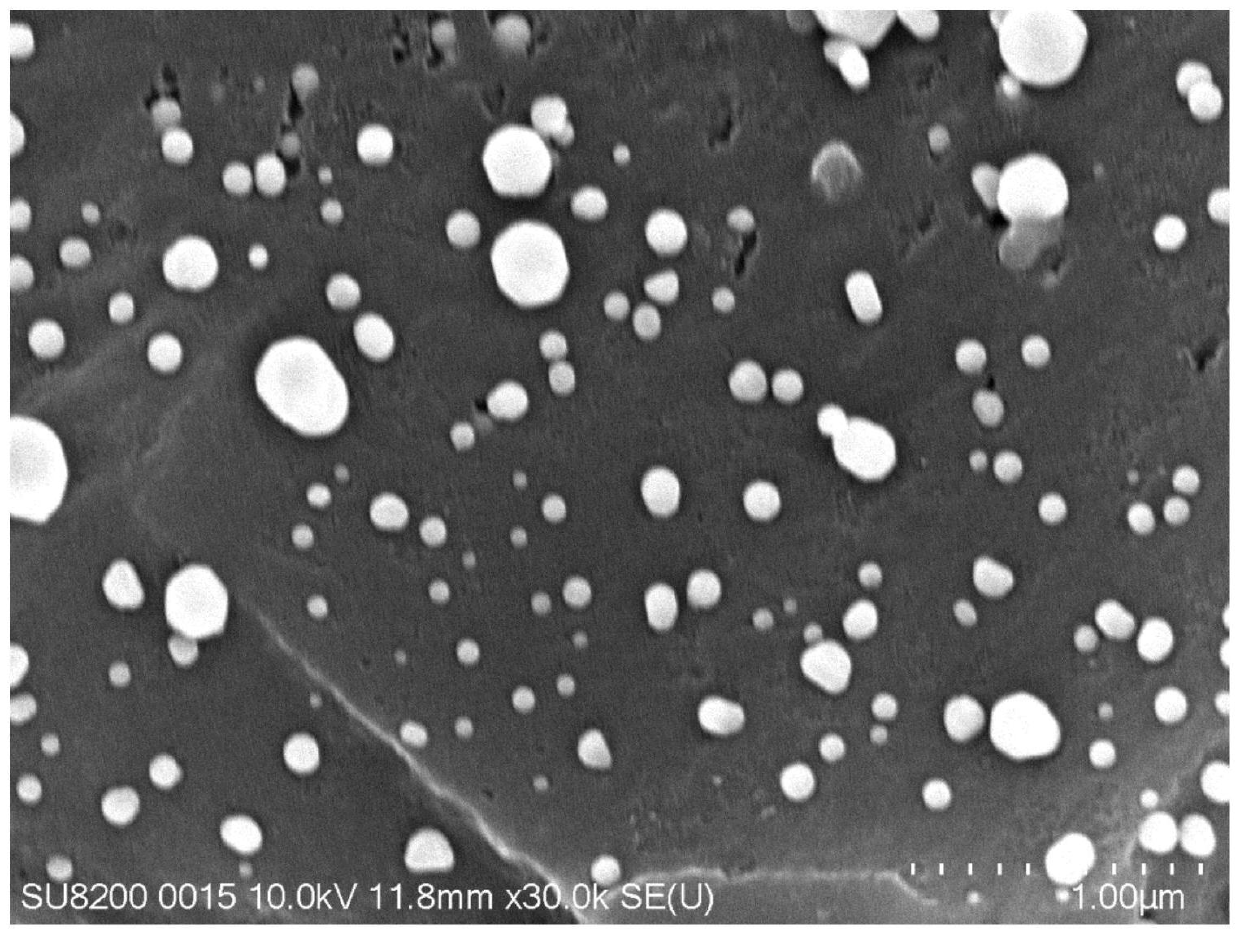

Embodiment 1

[0044] The present embodiment is the nanoparticle activated carbon of loading CoCr(Mn / Al)FeNi high entropy alloy for methylene blue (C 16 h 18 CN 3 S·3H 2 O) Catalytic degradation of azo dye solution using nanoparticle activated carbon loaded with CoCrMnFeNi or CoCrAlFeNi high-entropy alloys.

[0045] Among them, the composition of the CoCrMnFeNi high-entropy alloy is shown in Table 1 below:

[0046] Table 1

[0047]

[0048] In the above three groups of nanoparticle activated carbon loaded with CoCrMnFeNi high-entropy alloy, the mass content of activated carbon is 90wt%, 95wt%, and 97wt%, respectively.

[0049] Among them, the composition of the CoCrAlFeNi high-entropy alloy is shown in Table 2 below:

[0050] Table 2

[0051]

[0052] In the above three groups of nano-particle activated carbon loaded with CoCrAlFeNi high-entropy alloy, the mass content of activated carbon is 90wt%, 95wt%, and 97wt%, respectively.

[0053] Choose activated carbon particles with m...

Embodiment 2

[0060] The present embodiment is the nanoparticle phosphate ceramics of the load CoCr (Mn / Al) FeNi high entropy alloy for methylene blue (C 16 h 18 CN 3 S·3H 2 O) catalytic degradation of the solution, in the nano-particle phosphate ceramics loaded with CoCrMnFeNi or CoCrAlFeNi high-entropy alloys, the mass content of the phosphate ceramics is 90wt%.

[0061] Among them, the composition of the CoCrMnFeNi high-entropy alloy is shown in Table 3 below:

[0062] table 3

[0063]

[0064] Among them, the composition of the CoCrAlFeNi high-entropy alloy is shown in Table 4 below:

[0065] Table 4

[0066]

[0067] Phosphate ceramics are a new type of structural and functional ceramic materials with a three-dimensional network structure but different compositions. The spatial structure of tetrahedral crystals and octahedrons with common vertices has the potential to be developed as a carrier material.

[0068] Weigh 3g of phosphate ceramic powder and wash the excess ash w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com