Stress-responsive multi-color-change composite film material as well as preparation method and application thereof

A composite film and multi-color technology, which is applied in the fields of instruments, optics, nonlinear optics, etc., can solve the problems of optical film difficulties and achieve the effect of excellent performance and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

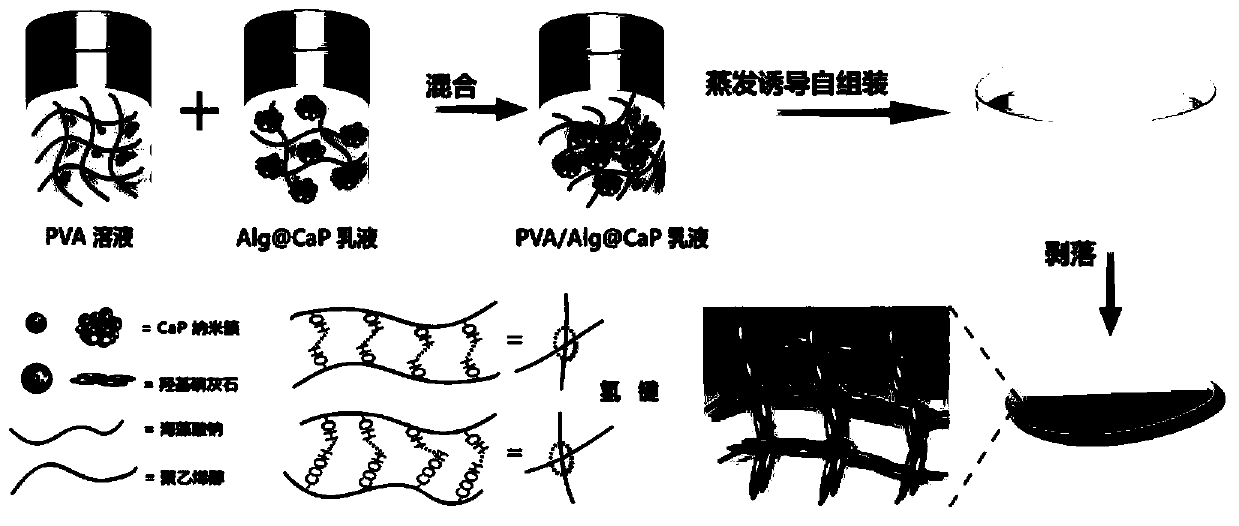

[0028] Such as figure 1 The shown preparation method prepares the composite film provided by the present invention: using calcium phosphate nanoclusters as the precursor of the inorganic unit, successively adding sodium alginate aqueous solution and polyvinyl alcohol aqueous solution to form a uniform emulsion, and preparing the composite film by evaporation induced self-assembly method, A large number of hydrogen bonds and ionic bond forces are formed inside the film, thereby giving the composite film excellent mechanical properties.

[0029] The specific preparation method is as follows:

[0030] Prepare calcium phosphate nanoclusters: prepare an ethanol solution of calcium chloride, dissolve 11.76g calcium chloride dihydrate in 1.60L absolute ethanol, add 221.79mL triethylamine, stir for 30min, then add phosphoric acid ethanol solution (4.18 (mL phosphoric acid dissolved in 80mL ethanol), stirred vigorously for 12h, obtained a white precipitate by centrifugation, repeatedly wash...

Embodiment 2

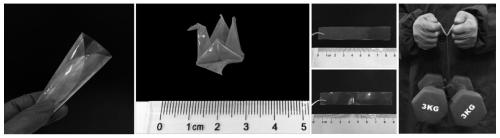

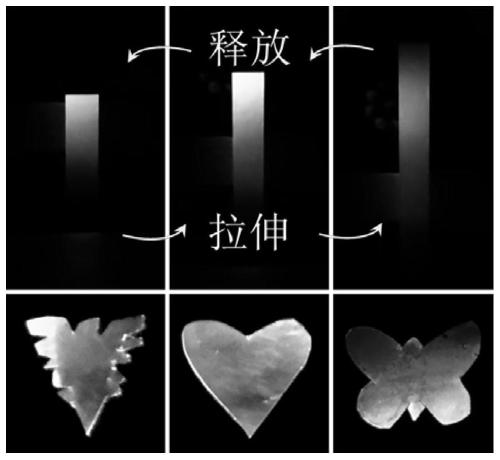

[0035] First, take 6 portions of 10 mL with a concentration of about 30 mg mL -1 Place the calcium phosphate nanoclusters in a 50mL centrifuge tube, centrifuge at 8000rpm for 5min, discard the supernatant, add 10mL of 0.5wt% sodium alginate aqueous solution and shake well, then add 10mL of 3.0wt% polyvinyl alcohol aqueous solution , Oscillate uniformly, transfer to a 250mL beaker, stir vigorously for 3h, finally transfer the homogeneous emulsion to a 12cm×12cm petri dish after ultrasonic debubbling, dry at room temperature, and finally peel off from the petri dish to obtain a dried composite film. The prepared composite film also exhibits excellent toughness and reversible multi-color changes under a polarized light system.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com