Three-dimensional porous lithium ion battery anode material of graphene composite material and preparation method of three-dimensional porous lithium ion battery anode material

A lithium-ion battery, three-dimensional porous technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of poor compatibility between graphite and engraving, irreversible capacity loss, etc., achieve simple and easy control of the reduction process, and improve cycle stability. Sexual, low-density effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Take raw material graphene oxide (GO) 100mg, titanium dioxide (TiO 2 ) 100mg, polyvinyl alcohol (PVA) 100mg, dissolved in 20ml deionized water, heated to 90°C in a water bath, stirred for 2h and mixed evenly;

[0035] GO / TiO 2 / PVA dispersion is placed in 5.3cm 3 Put it in a silica gel mold, put it in a freezer at -30°C for 24 hours, take it out, put the obtained solid into a freeze dryer at -50°C, 10Pa for 24 hours, and obtain a cylindrical polyvinyl alcohol-regulated solid GO / TiO 2 / PVA three-dimensional porous material.

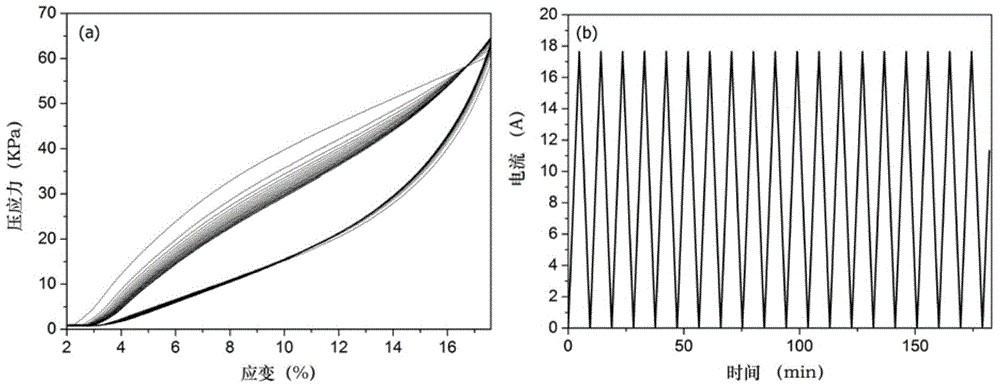

[0036] The obtained product was heated to 250° C. in a vacuum heat treatment furnace at a heating rate of 3° C. / min, and kept at a pressure of 50 Pa for 30 minutes. The highly elastic three-dimensional porous r-GO / TiO 2 / PVA material.

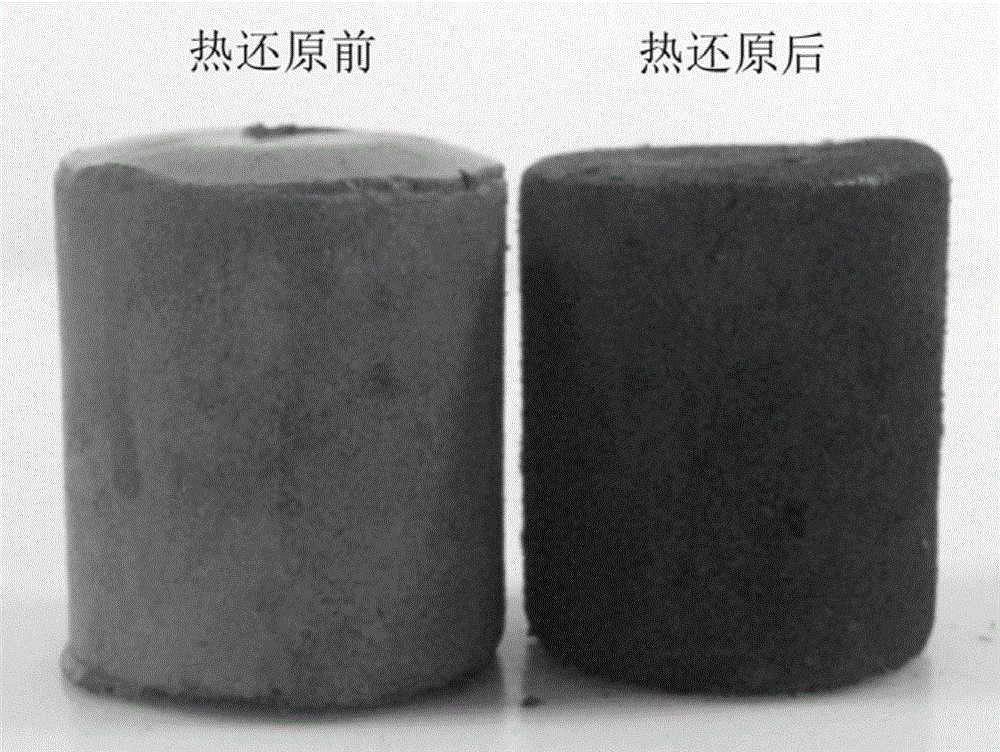

[0037] The shape and size of 3D porous graphene / semiconductor nanoparticle composites, such as figure 1 shown. It can be seen that the solid GO / TiO before reduction 2 / PVA material presents the tan color of G...

Embodiment 2

[0044] Take raw materials graphene oxide (GO) 100mg, silicon powder (Si) 100mg, polyvinyl alcohol (PVA) 50mg, dissolve in 50ml deionized water, heat to 90°C in a water bath, stir for 3h and mix well;

[0045] The obtained product was divided into silica gel molds, put into a freezer at -30°C for 24 hours, and then taken out, and the obtained solid was placed in a freeze dryer at -50°C and 10 Pa for 30 hours of sublimation drying to obtain a cylindrical polyvinyl alcohol adjustment solid three-dimensional porous graphene oxide composites.

[0046] The obtained product was heated in a vacuum heat treatment furnace to 280° C., kept for 30 minutes, and the pressure was at normal pressure. That is, a highly elastic three-dimensional porous r-GO / Si / PVA material was obtained.

Embodiment 3

[0048] Get raw material graphene oxide (GO) 100mg, ferric oxide (Fe 3 o 4 ) 100mg, polyvinyl alcohol (PVA) 40mg, dissolved in 20ml deionized water, heated to 80°C in a water bath, stirred for 2h and mixed evenly;

[0049] The obtained product is divided into 5.3cm 3 Put it in a silica gel mold, freeze it in a freezer at -30°C for 18 hours, take it out, and put the obtained solid into a freeze dryer at -50°C, 10Pa for 36 hours of sublimation drying to obtain a cylindrical polyvinyl alcohol-regulated solid GO / Fe 3 o 4 / PVA three-dimensional porous material.

[0050] Heat the obtained product to 300°C in a vacuum heat treatment furnace, keep it warm for 50min, and keep the pressure at 100Pa. The highly elastic three-dimensional porous r-GO / Fe 3 o 4 / PVA material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com