Wheat straw powder composite wire for fused deposition modeling and preparation method and 3D (Three-Dimensional) printing method thereof

A technology of fused deposition modeling and composite wire, which is applied in the direction of additive processing, processing drive devices, etc., can solve the problems of not meeting market demand, high price, and slow development of 3D printing materials, so as to save printing time and enhance mechanical properties , Improve the effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0031] A wheat straw powder composite wire for fused deposition molding, the raw material of the wheat straw powder composite wire for fused deposition molding comprises wheat straw powder, polylactic acid, coupling agent, compatibilizer, lubricant, and the weight part of the wheat straw powder The number of parts is 1 part, the parts by weight of the polylactic acid are 95 parts, the parts by weight of the coupling agent are 0.02 parts, the parts by weight of the compatibilizer are 0.5 parts, the parts by weight of the The weight part of the agent is 0.2 part.

[0032] In the wheat straw powder composite wire for fused deposition molding in this embodiment, the particle size of the wheat straw powder is 100-120 mesh; the polylactic acid in this embodiment is a polycondensate of lactic acid; The coupling agent is silane coupling agent KH550; the compatibilizer described in this embodiment is maleic anhydride grafted polyethylene copolymer; the lubricant described in this embod...

specific Embodiment approach 2

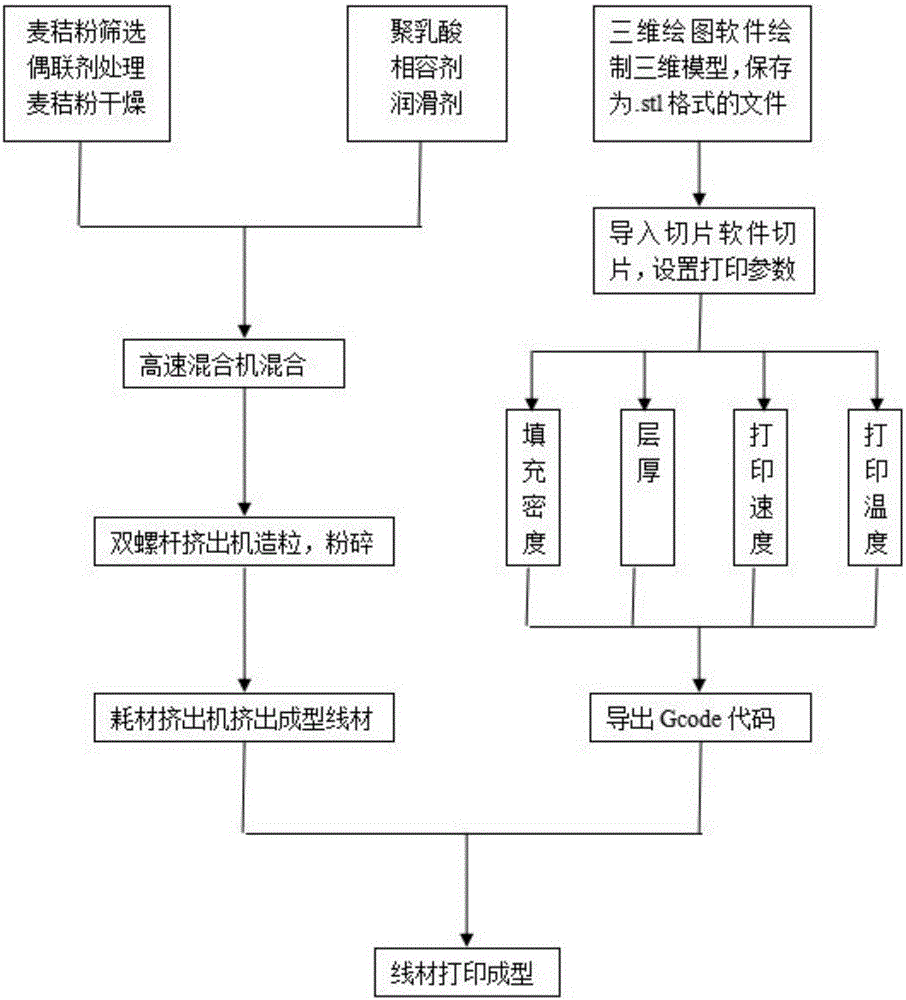

[0042] According to the 3D printing method of the wheat straw powder composite wire for fused deposition modeling according to the first embodiment, the method includes the following steps:

[0043] Step A, draw the corresponding three-dimensional solid model by using three-dimensional drawing software, save it as a file in .stl format, and import it into the slicing software;

[0044] Step B. Set the corresponding printing mode, the filling density is 20%, the layer thickness is 0.2mm, the printing speed is 20mm / s, and the printing temperature is 190℃;

[0045] Step C. The slicing software saves the parameters set in Step A and Step B as a Gcode code of the printing path recognizable by the 3D printer. The 3D printer works under the guidance of the code, stacks and manufactures layer by layer, and prints a three-dimensional solid model.

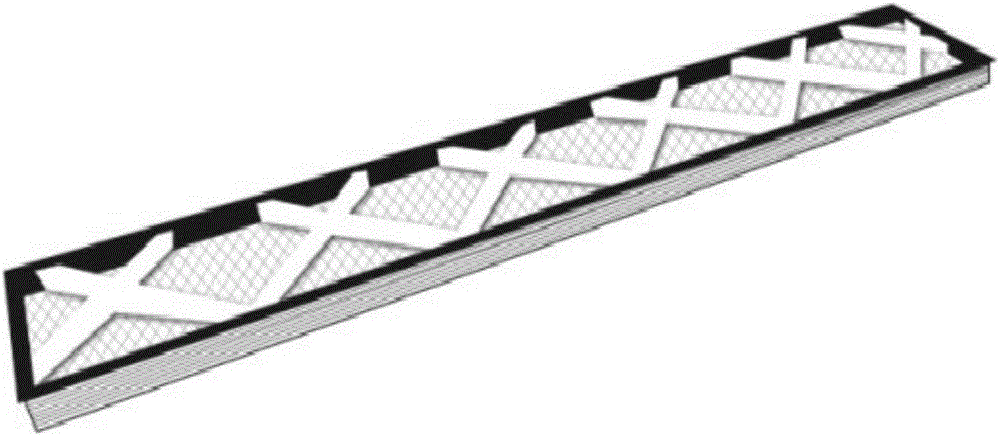

[0046] The conceptual diagram of the entity model printed according to this embodiment is as follows image 3 , Figure 5 As shown in the...

specific Embodiment approach 3

[0052] A wheat straw powder composite wire for fused deposition molding, the raw material of the wheat straw powder composite wire for fused deposition molding comprises wheat straw powder, polylactic acid, coupling agent, compatibilizer, lubricant, and the weight part of the wheat straw powder 5 parts by weight, 99 parts by weight of the described polylactic acid, 0.4 parts by weight of the described coupling agent, 1.5 parts by weight of the described compatibilizer, 1.5 parts by weight of the described lubricating agent The weight part of the agent is 1 part.

[0053] In the wheat straw powder composite wire for fused deposition molding in this embodiment, the particle size of the wheat straw powder is 100-120 mesh; the polylactic acid in this embodiment is a polycondensate of lactide; The coupling agent used is silane coupling agent KH550; the compatibilizer described in this embodiment is maleic anhydride grafted polypropylene copolymer; the lubricant described in this em...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com