Method for monitoring and positioning concrete cracks by using elastic conducting film sensor and infrared thermal imaging technique

An infrared thermal imaging and elastic conductive technology, which is applied in the field of monitoring and positioning concrete cracks with elastic conductive film sensors and infrared thermal imaging technology, can solve the problems of not being able to show deformation, the exact position of the crack point, and not being able to show deformation, etc., to achieve The effect of small thermal inertia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

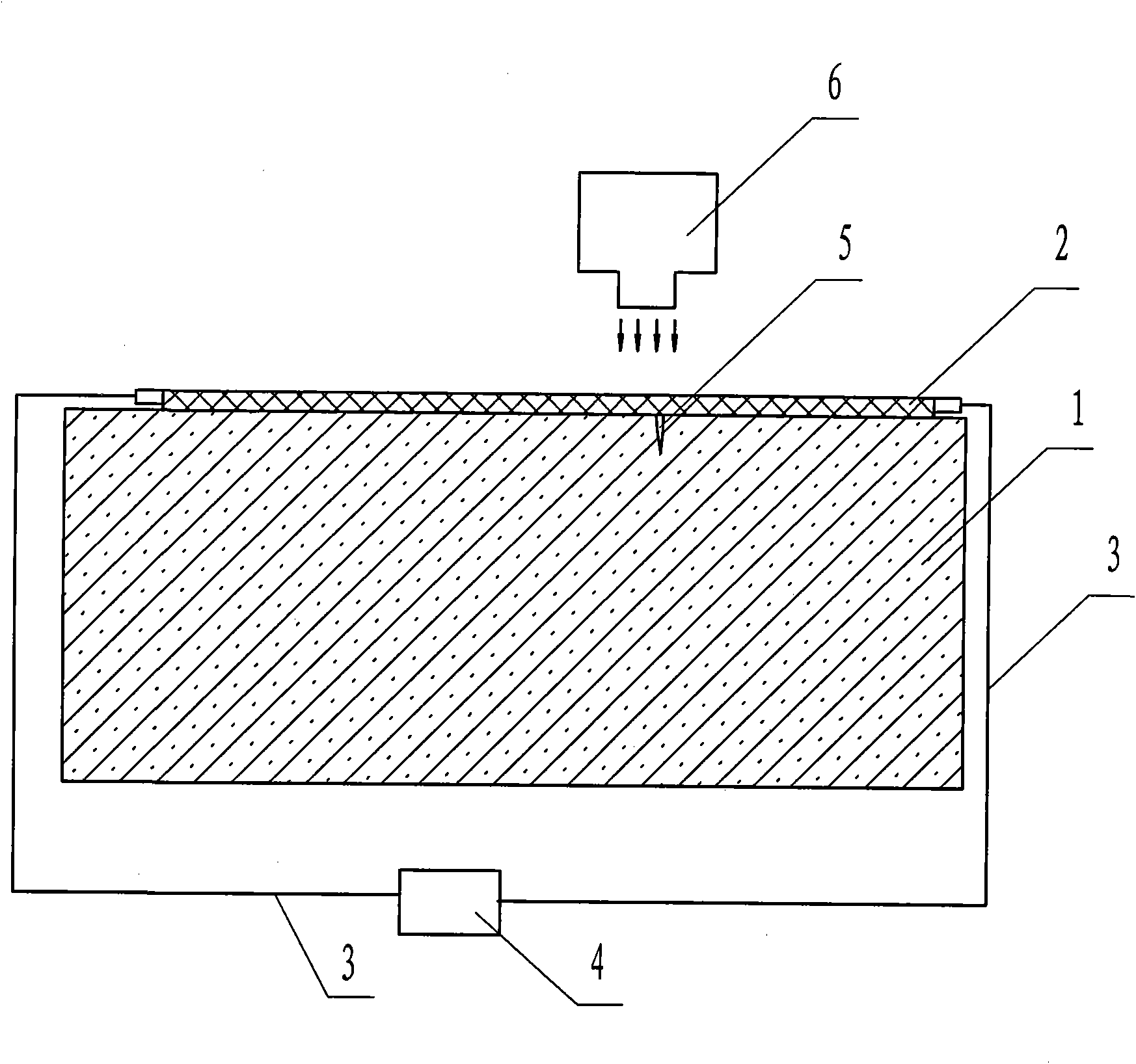

[0014] The method for monitoring and locating concrete cracks by the elastic conductive film sensor and infrared thermal imaging technology of the present invention is characterized in that it comprises the following steps:

[0015] 1. Curing the conductive paint to form an elastic conductive film, or making an elastic conductive film from a conductive rubber belt, and laying the elastic conductive film on the concrete member, or directly coating the conductive paint on the surface of the concrete member to form an elastic conductive film. Wires are arranged at both ends of the elastic conductive film to form an elastic conductive film sensor; the best way is to apply it on the surface of the concrete member;

[0016] 2. After cracks are found in the concrete components or during routine inspections, connect the wires at both ends of the elastic conductive film to the power supply for energization and heating;

[0017] 3. The elastic conductive film located at the crack part i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com