Concrete pole rebar quality tester and detection method by using tester

A cement rod and detector technology, which is applied to instruments, measuring devices, scientific instruments, etc., can solve the problems of insufficient diameter, corrosion, and insufficient number of steel bars, and achieve the effects of convenient operation, simple manufacturing, and scientific and reasonable detection methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

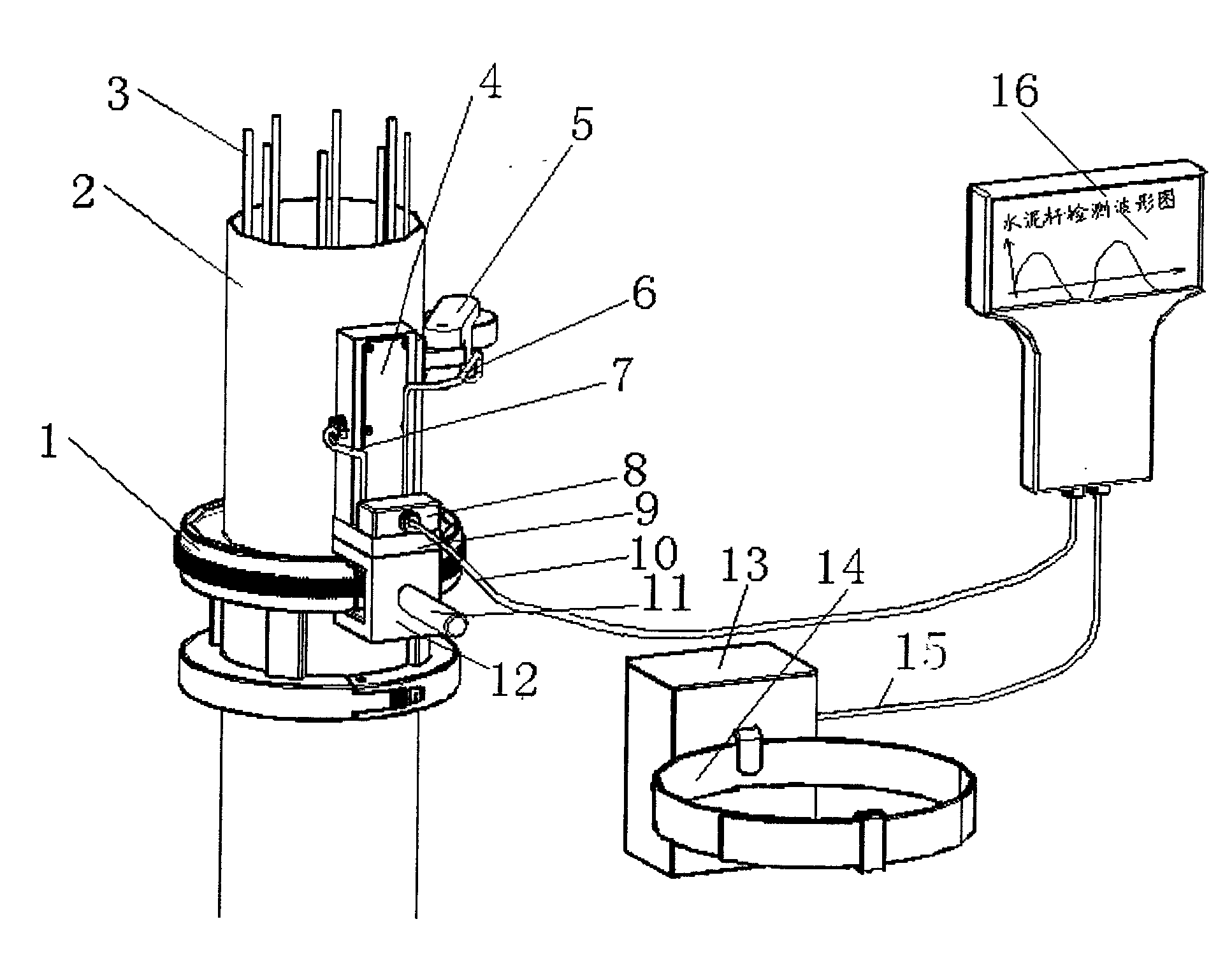

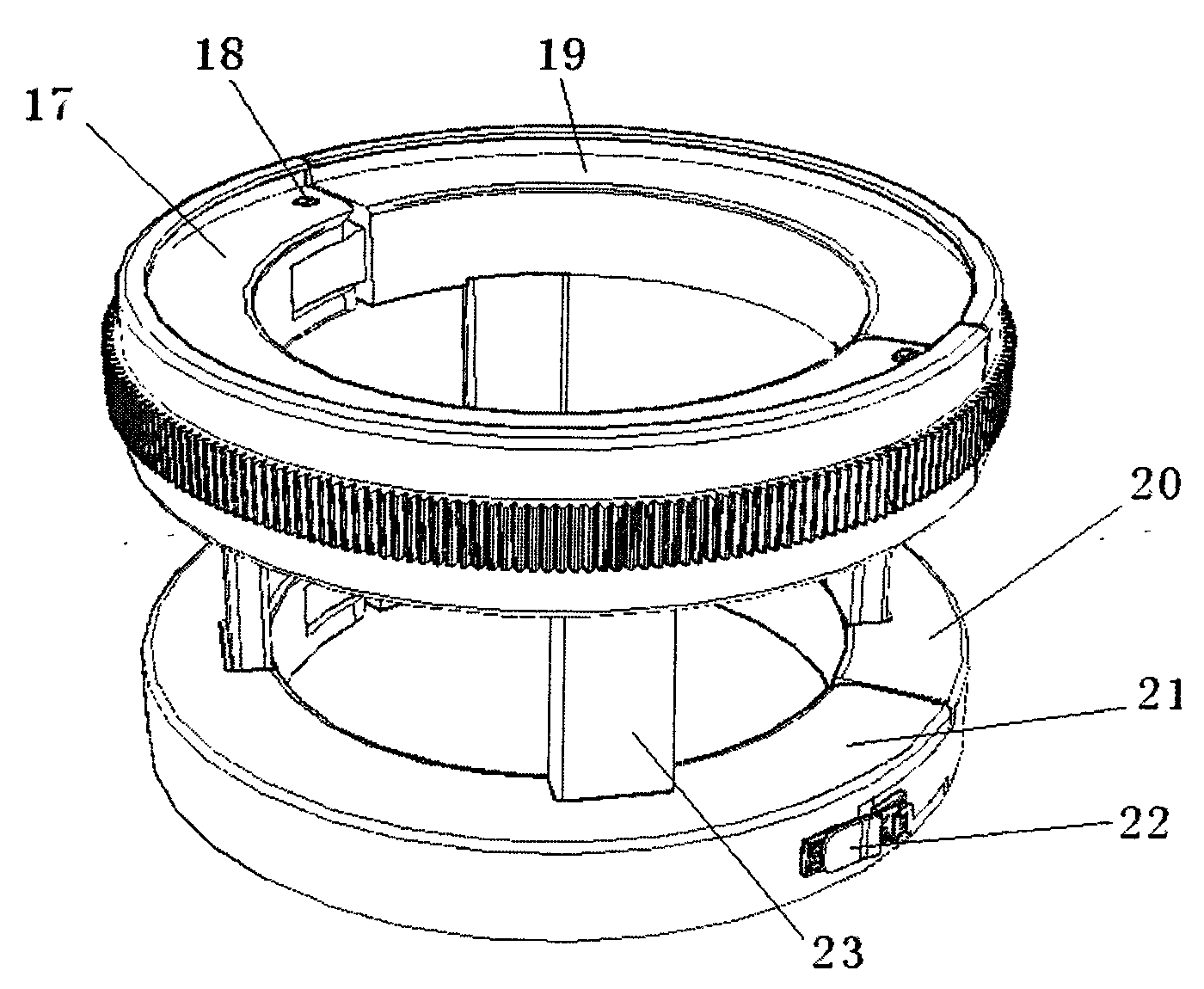

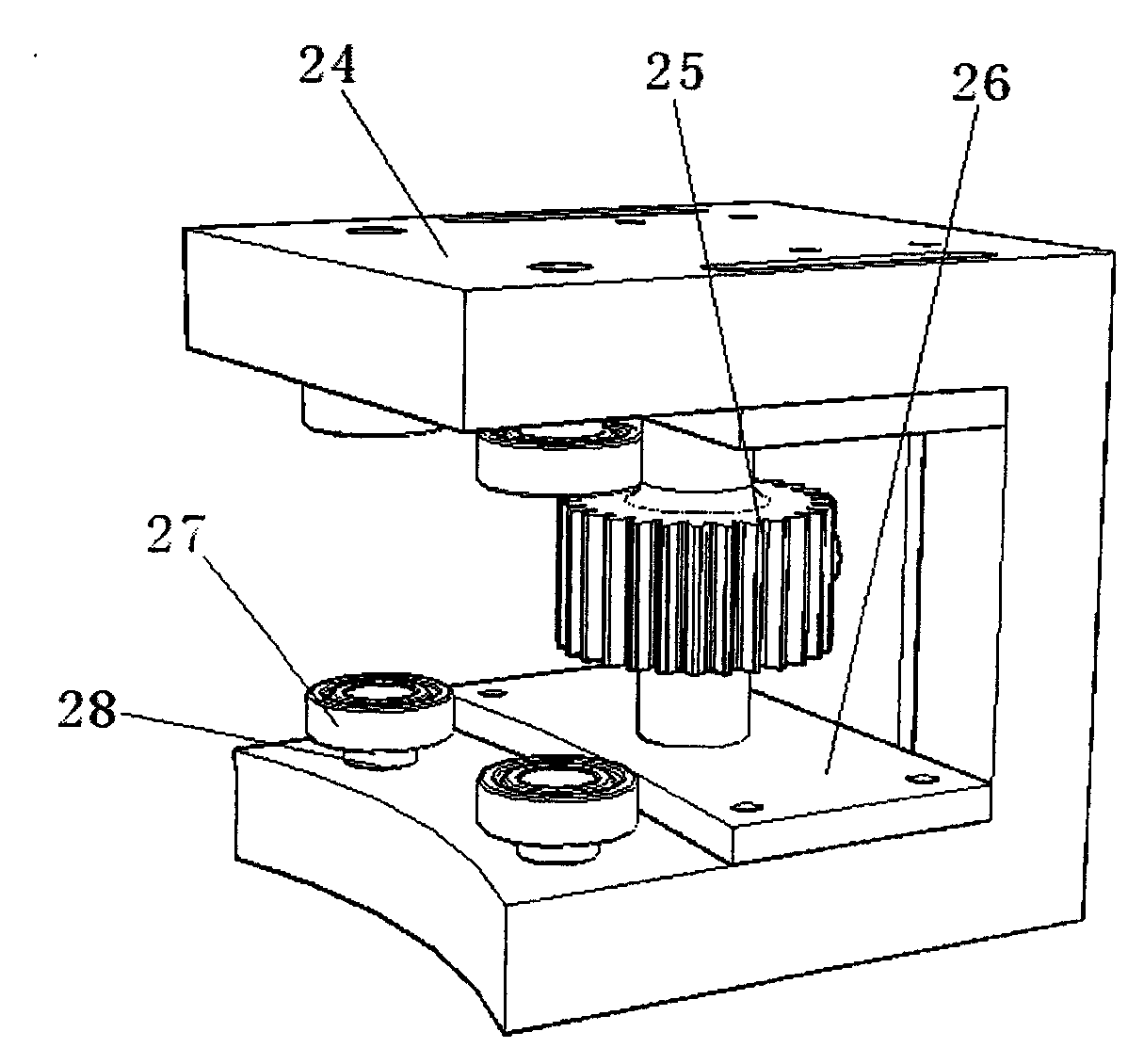

[0026] The detector of the present invention consists of a fixed bracket 1 that can be sleeved on the cement rod 2 to be tested, an exciter 4, a rotary encoder 5, a battery box, and a magnetic measuring element installed together with the exciter 4, a signal preprocessor, an ARM processor etc.

[0027] The present invention will be described in detail below with reference to the accompanying drawings.

[0028] refer to figure 1 , The fixed bracket 1 of the detector is set on the cement rod 2; the exciter 4 is fixed on the detection support 12 through the connecting plate 9. The rotary encoder 5 is installed on the exciter, and the magnetic measuring element is installed on the armature of the exciter. Handle 11 is housed on the detection support. The signal line 7 of the magnetic measuring element and the signal line 6 of the rotary encoder are connected to the signal pre-processor 8, and the output signal line 10 of the signal pre-processor is connected to the ARM processo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com