Apparatus and methods for winding supports for coils and single poles of cores of dynamo electric machines

a technology supports, which is applied in the direction of metal working apparatus, inductance/transformer/magnet manufacture, manufacturing tools, etc., can solve the problems of early failure of dynamo electric machines, and achieve the effect of accurate deformation and increasing filling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

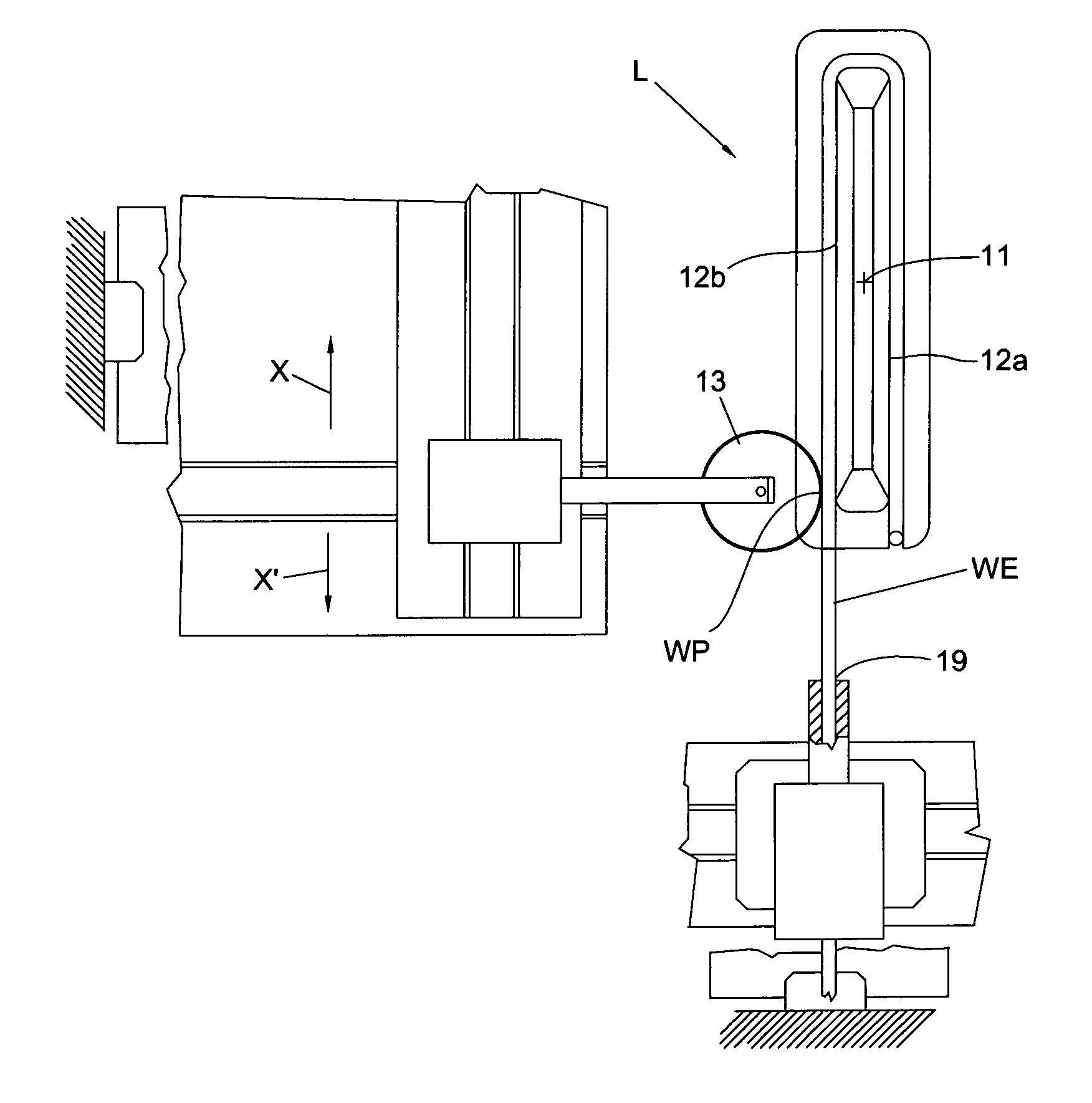

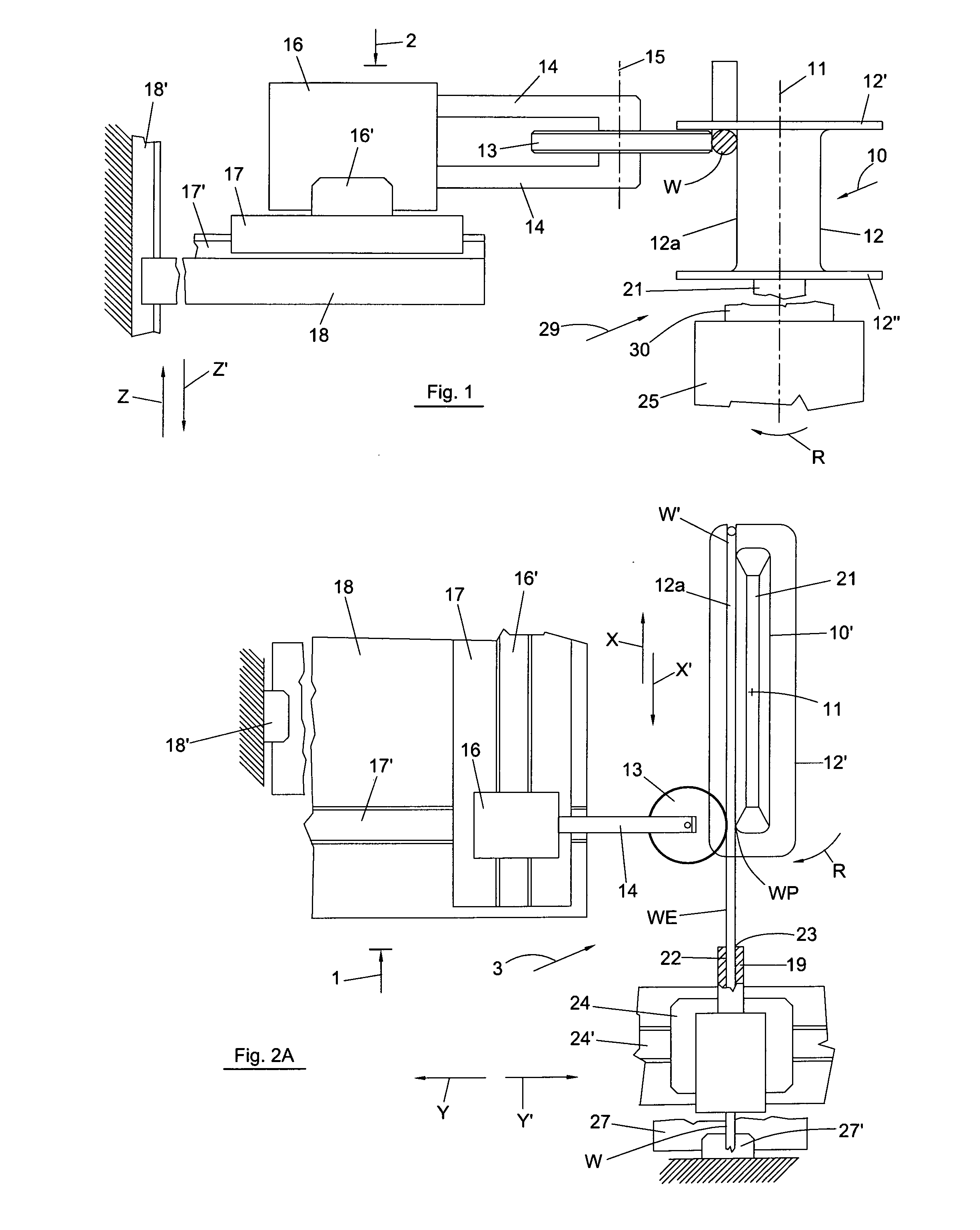

[0051]With reference to FIGS. 1 and 2 the apparatus of the invention is provided with an assembly 29 for holding and rotating a coil support 10. The assembly comprises a holding member 21, which becomes inserted in hollow portion 10′ of coil support 10.

[0052]Coil support 10 comprises a central portion 12 and opposite flanges 12′ and 12″. Wire W is wound around portion 12 up to flanges 12′ and 12″ to form a coil C of a certain number of turns, as shown in FIG. 3.

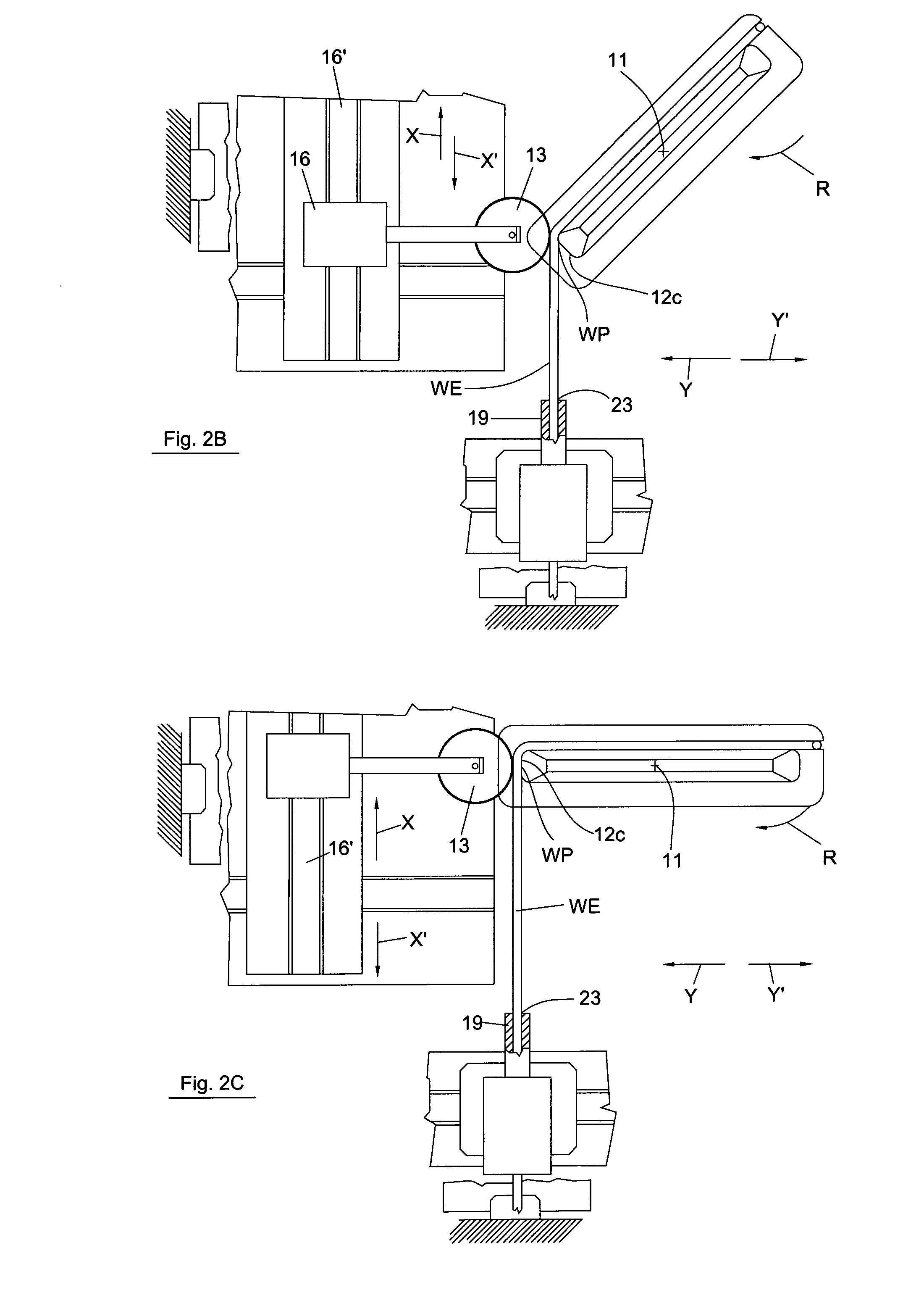

[0053]In FIGS. 2A-2E superior flange 12′ has been made transparent to show parts that would otherwise be hidden in the views from direction 2.

[0054]With reference to FIG. 2A, member 21 applies a grip on the internal surface of hollow portion 10′ to hold coil support 10 in alignment with rotation axis 11. Axis 11 can be aligned with an axis of symmetry of the coil support, as shown in FIGS. 1, 2A-2E. During winding, coil support 10 rotates with rotation R around axis 11 by rotating holding member 21 with drive unit 25.

[0055]As...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| speed | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com