Low-carbon high-sulfur free-cutting steel with excellent cutting performance and manufacturing method thereof

A technology of cutting performance and free-cutting steel, applied in the field of free-cutting steel, can solve problems such as poor surface finish of parts, and achieve the effects of excellent cutting performance, improved service life, and improved hot working performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

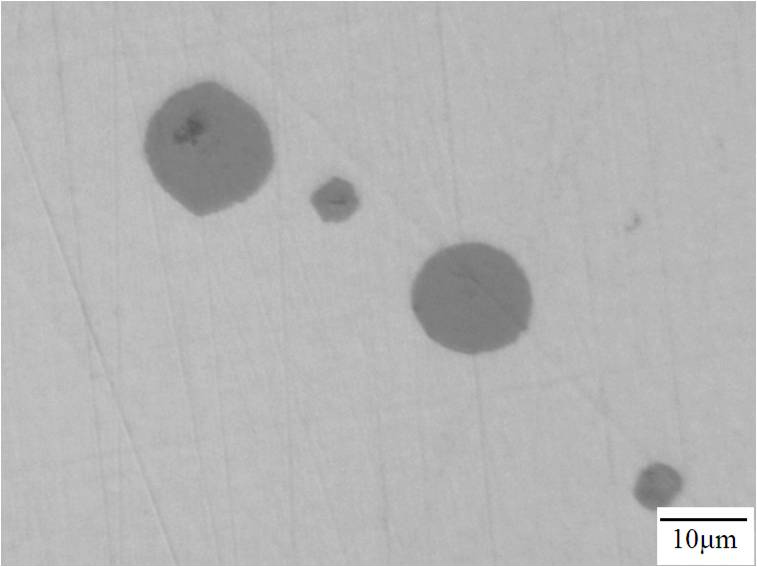

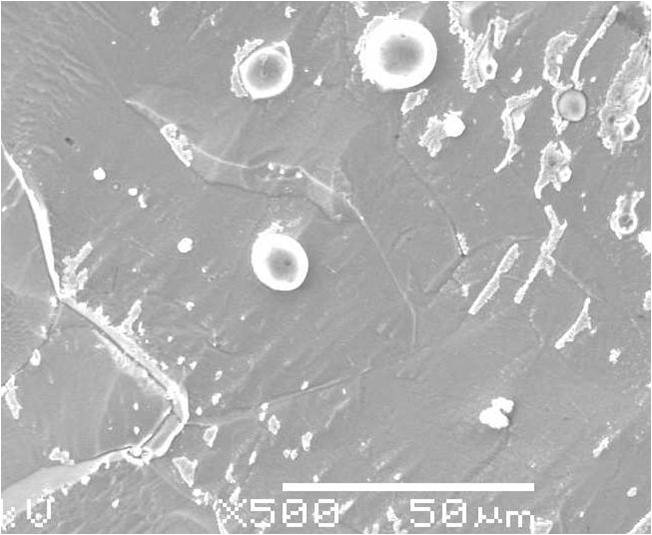

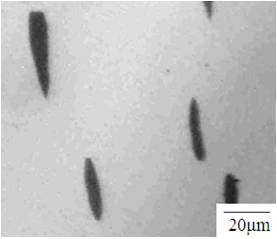

Image

Examples

Embodiment Construction

[0038] In order to further understand the content of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0039] The main chemical composition (mass percentage) range of the low-carbon high-sulfur free-cutting steel of the present invention is: C: 0.05-0.2%, Mn: 0.6-2.0%, P: 0.04-0.1%, S: 0.2-0.45%, O : 0.005~0.02%, N≤0.02%, Te: 0.005~0.1%, Si≤0.005%, Al≤0.001%, the rest is Fe and unavoidable impurity elements.

[0040] The manufacture method flow process of the present invention is as follows:

[0041] Steel scrap (or blast furnace molten iron) → induction furnace (or converter or electric furnace) → (LF furnace refining) → die casting (or continuous casting) → rolling → cooling.

[0042] The main processes controlled during the manufacturing process are as follows:

[0043] (1) During induction furnace (or converter or electric furnace) smelting, avoid containing a large amount of Si a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com