Assembling type steel tube concrete combination column

A concrete-filled steel tube, prefabricated technology, applied in the direction of columns, piers, pillars, etc., to achieve the effects of large contact area, reliable bonding and anchoring strength, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

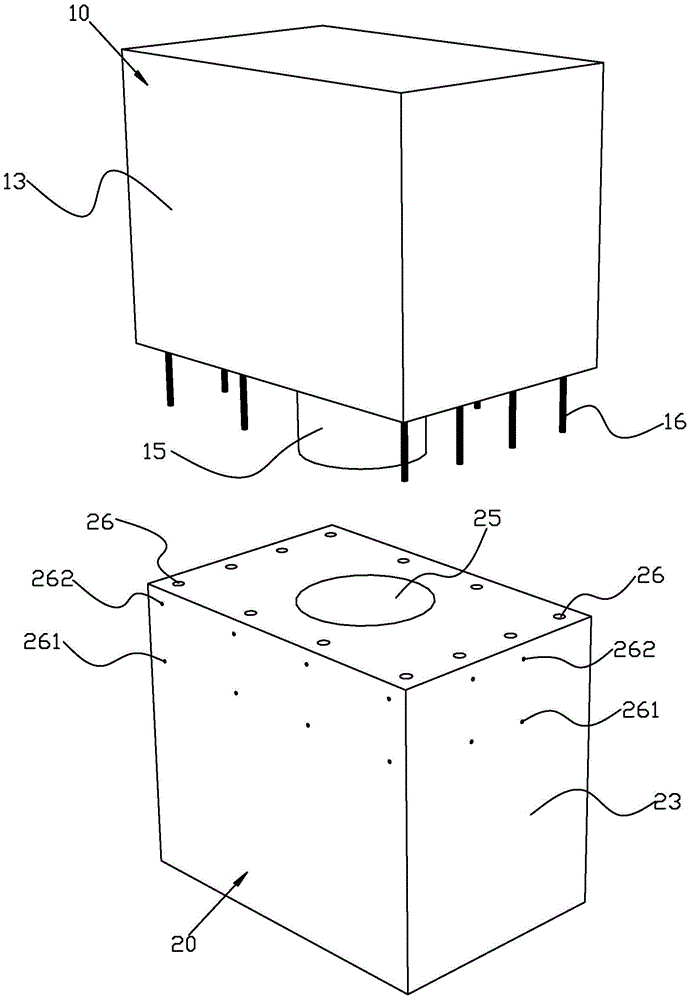

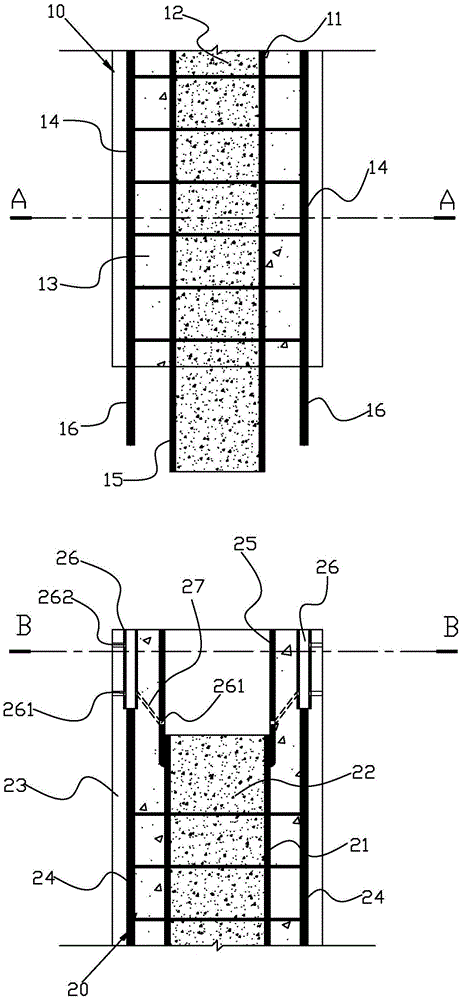

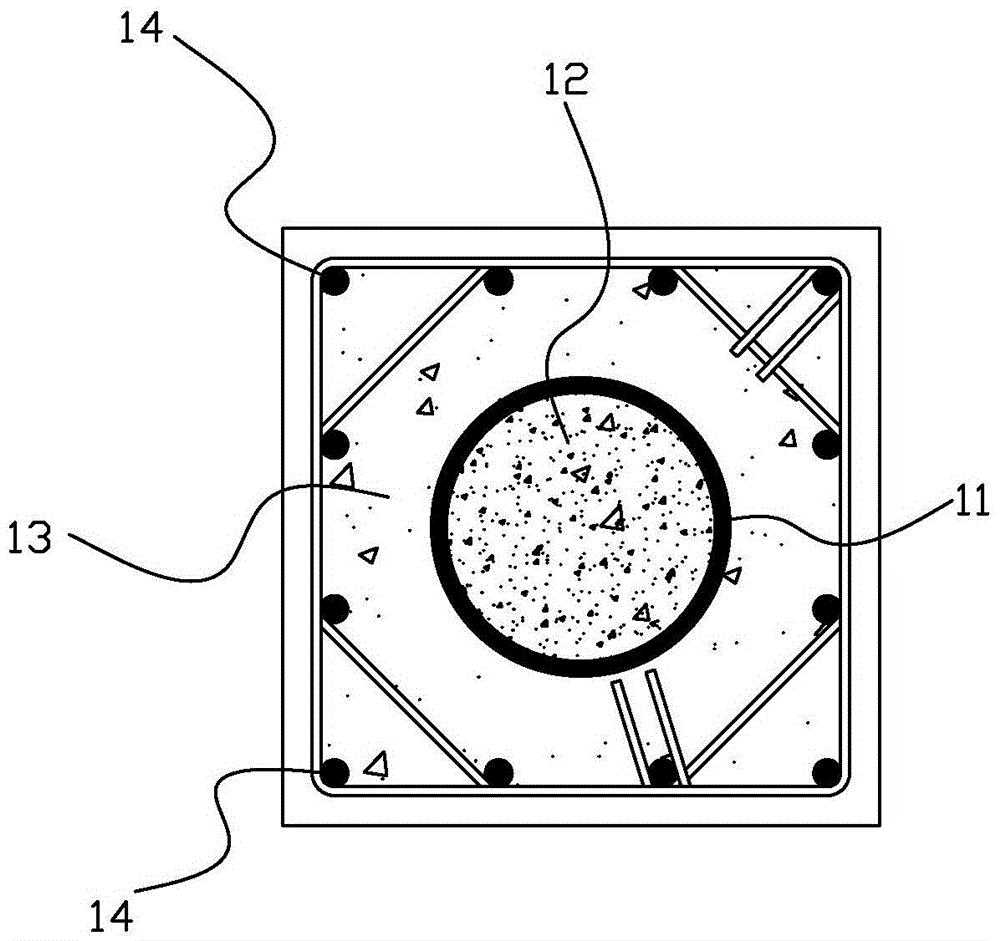

[0027] Please check Figure 1 to Figure 5 , the fabricated steel pipe concrete composite column, including a first column section 10 and a second column section 20 .

[0028] The first column section 10 includes a first steel pipe 11 and a reinforcement cage arranged outside the first steel pipe 11. The first steel pipe 11 is filled with high-strength concrete 12. Concrete is poured on the first steel pipe 11 and the reinforcement cage to form the first external concrete. 13. The first steel pipe 11 has an insertion portion 15 protruding from the first mating surface of the first external concrete portion 13, and the first longitudinal reinforcement 14 of the steel cage has a reserved section 16 protruding from the first mating surface, preferably , the protruding length of the socket part 15 is slightly greater than the protruding length of the reserved section 16 . The first steel pipe 11 is longitudinally arranged in the center of the first outer concrete part 13 and const...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com