Movable oil pipe box for oil/water well operation

A mobile, oil pipe technology, applied in the direction of drilling pipe, casing, drilling equipment, etc., can solve the problems that affect the physical and mental health of operators, affect the environmental quality of mining areas, and high labor intensity of workers, so as to achieve high labor intensity of workers and improve the working environment , the effect of reducing the cost of measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to further disclose the technical solutions of the present invention, the following will be described in detail through examples in conjunction with the accompanying drawings:

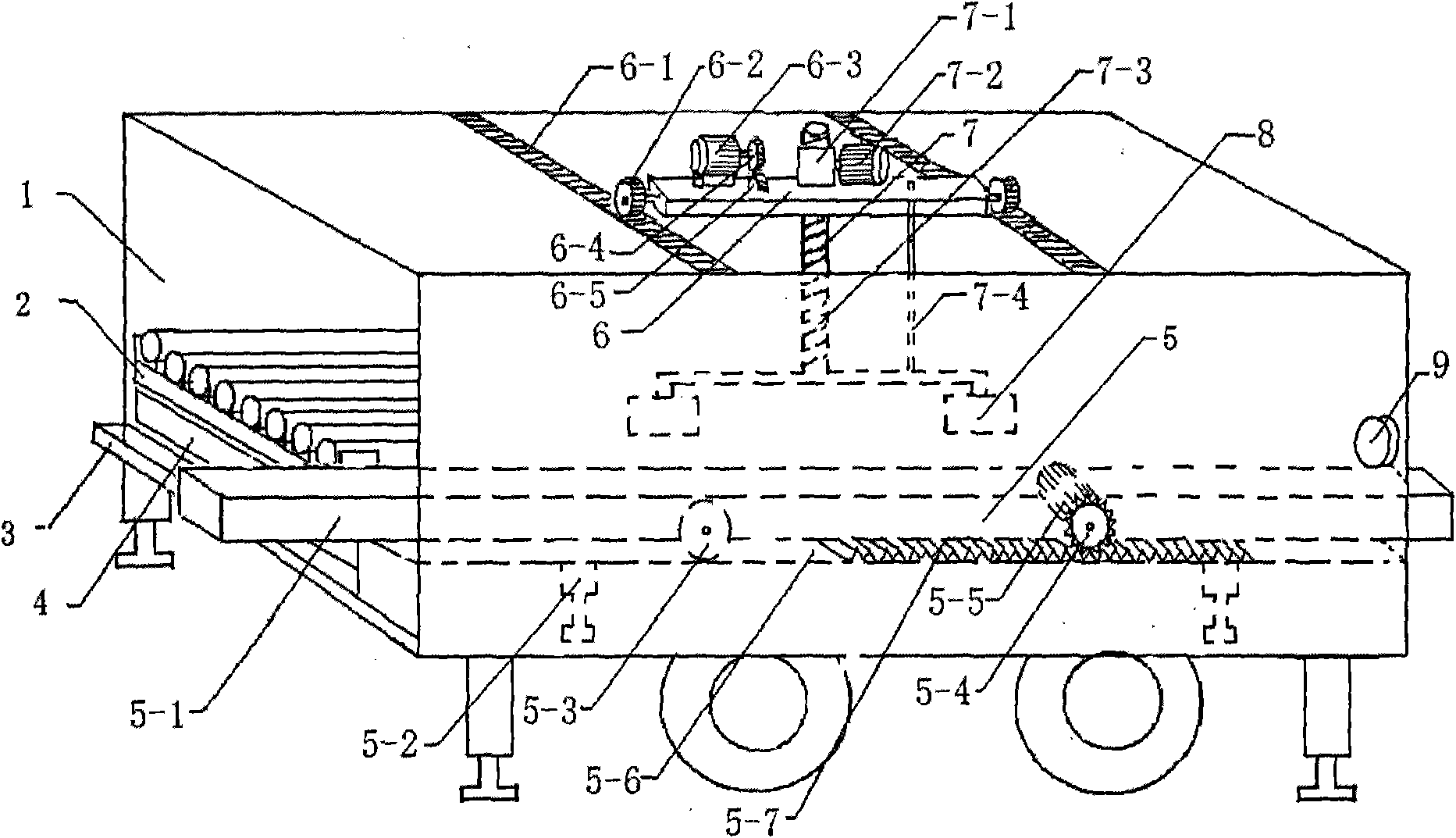

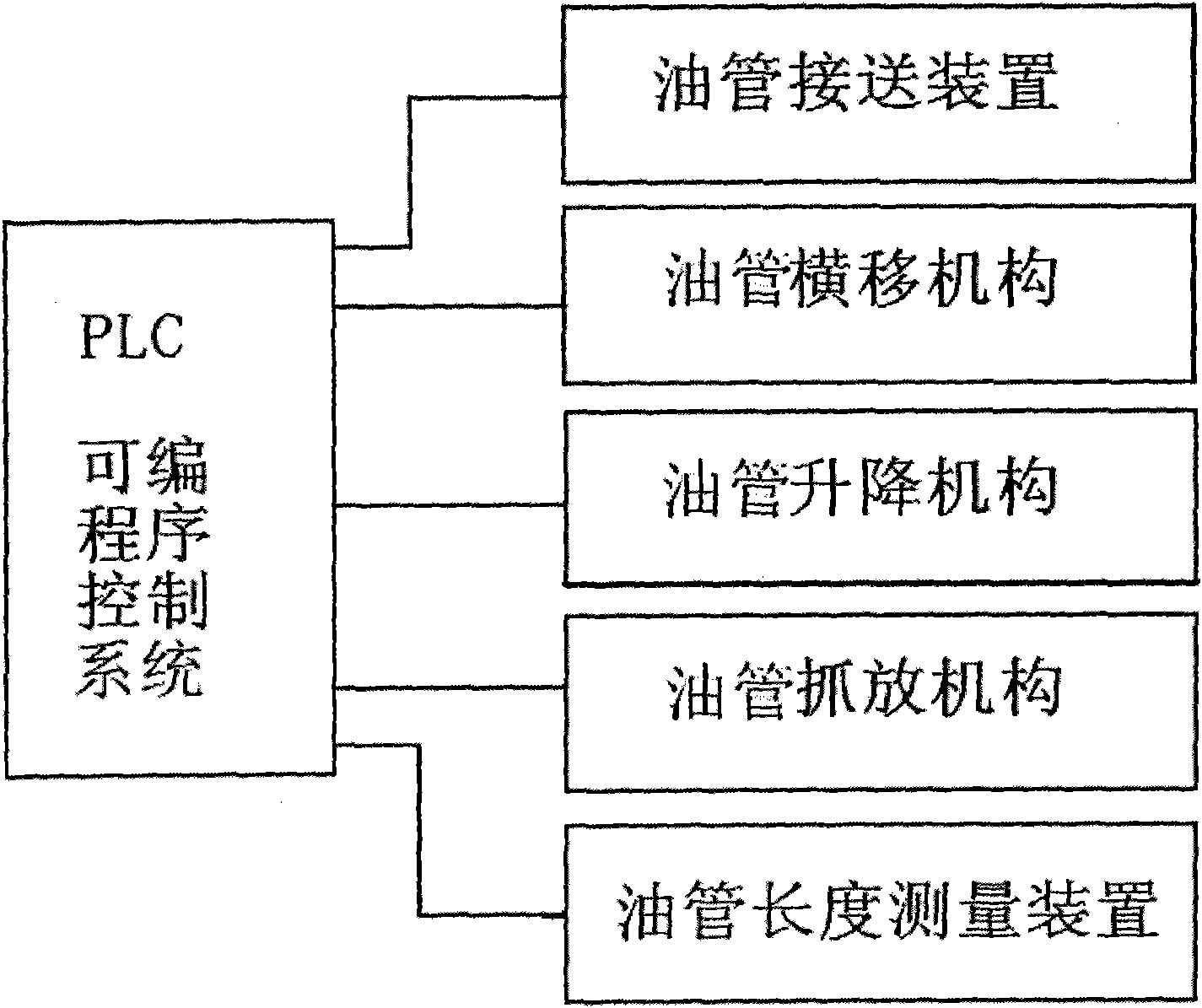

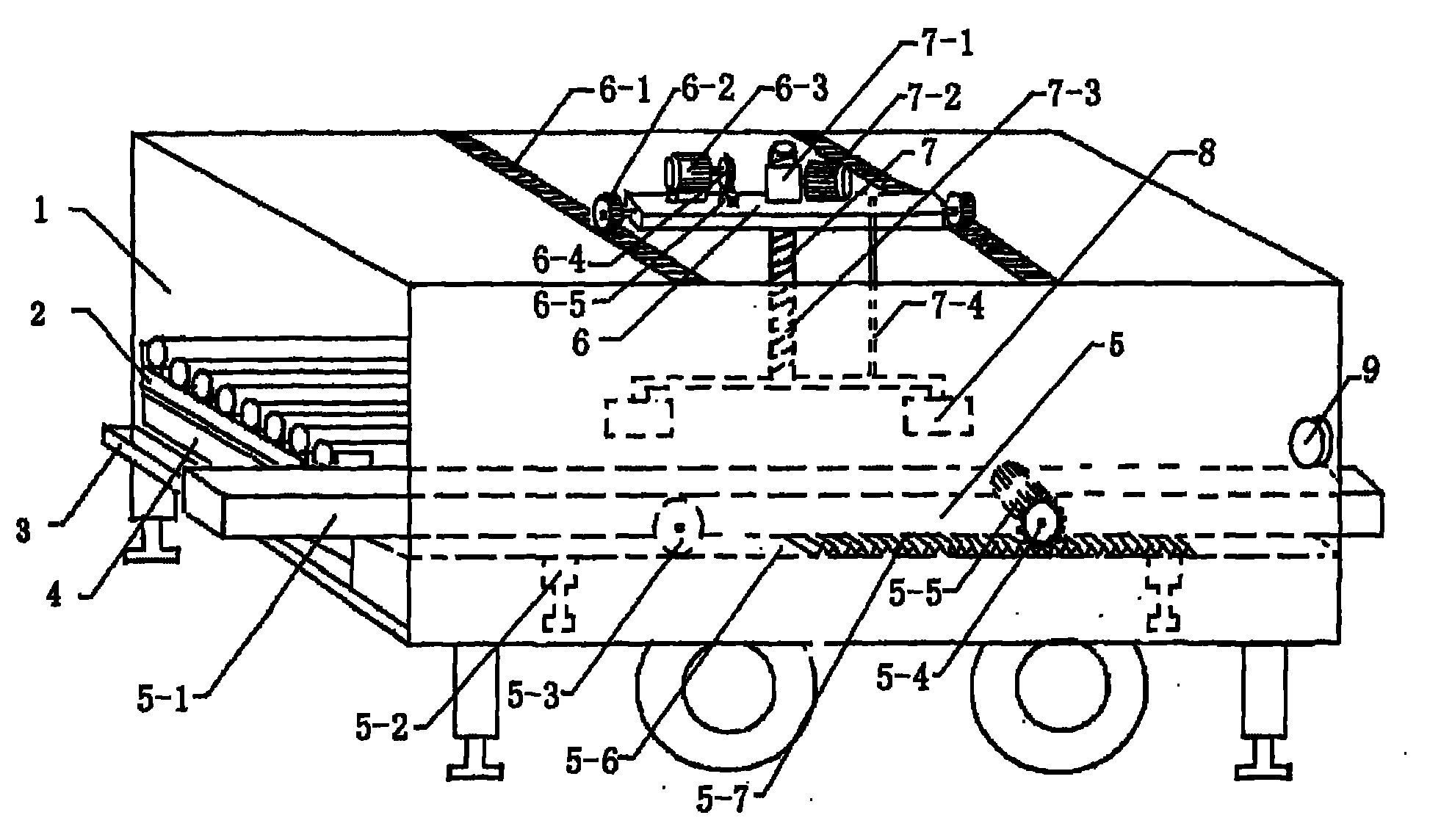

[0018] Such as figure 1 , 2 As shown, the operation mobile tubing box is a kind of oil and water well operation storage pipe device, which includes a tubing box 1, a tubing support 2, a trailer chassis 3, a sewage tank 4, a tubing pick-up device 5, a mobile platform 5-1, Lifting hydraulic cylinder 5-2, mobile platform driven wheel 5-3, gear 5-4, motor 5-5, bottom plate 5-6, rack 5-7, oil pipe traverse mechanism 6, traverse rack 6-1, Traversing gear 6-2, traverse motor 6-3, driving gear 6-4, driven gear 6-5, oil pipe lifting mechanism 7, lifting turbine 7-1, lifting motor 7-2, lifting worm 7-3 , guide rod 7-4, oil pipe pick-and-place mechanism 8, oil pipe length measuring device and PLC (programmable logic controller) system 9.

[0019] The oil pipe box is set as a rectangle, and is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com