Axial embedded blast hole of reinforced concrete beam and blasting demolition method

A technology of reinforced concrete beams and blastholes, which is applied in blasting, building maintenance, construction, etc., can solve the problems of blasting blockage and blasting network connection operation, heavy workload, multiple detonators and blocking materials, and easy misoperation, etc., to achieve improvement Effect of blasting and fragmentation, reduction of consumption of explosives and detonators, effect of reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The width×height×length of the reinforced concrete beam is 0.4m×0.6m×4m, and the PVC pipe with a diameter of 30 mm is embedded as the embedded blast hole, which is arranged on the longitudinal center axis of the beam, the length is 4 m, and the two ends are open in the beam End cross section. Emulsion explosives have a diameter of 25mm and a length of 0.2m, with a discontinuous charge structure and 0.2m spacing.

[0039] According to the above-mentioned axial embedded blast hole and blast hole charge structure, the construction process of the present invention is:

[0040] 1) Destroy the concrete protective layer, find the PVC embedded pipe, and clean the pipe with compressed air;

[0041] 2) Bind the drug pack on the detonating cord discontinuously at 0.2m intervals, and then send it into the embedded pipe;

[0042] 3) Detonate the detonating cord.

Embodiment 2

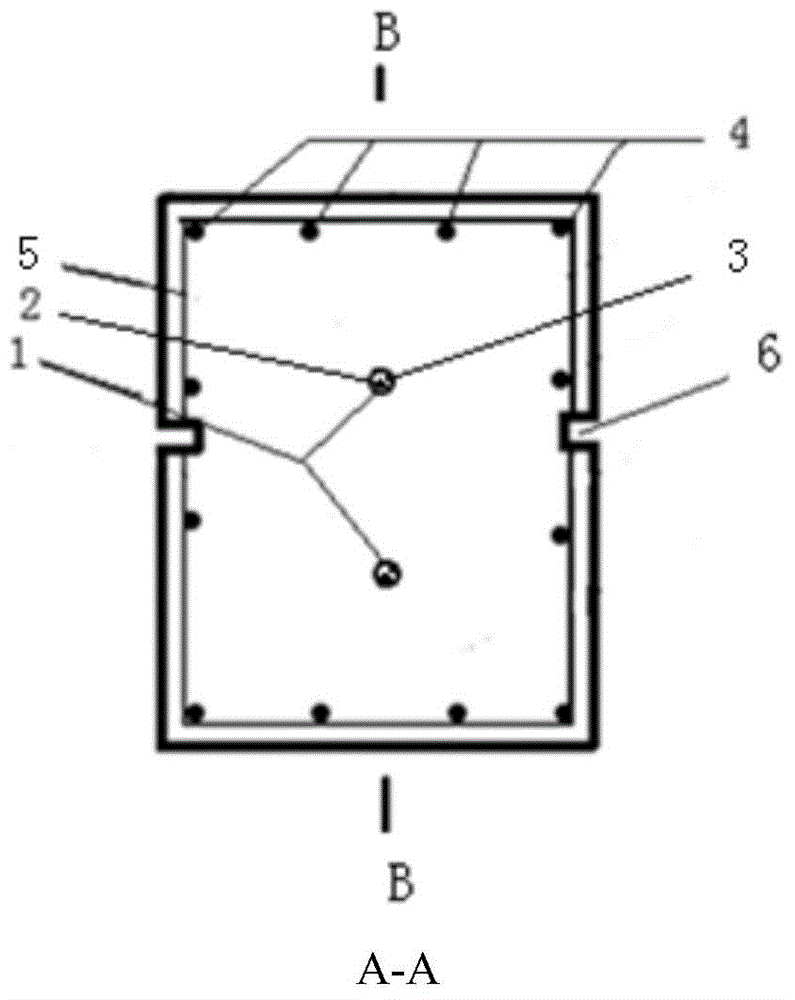

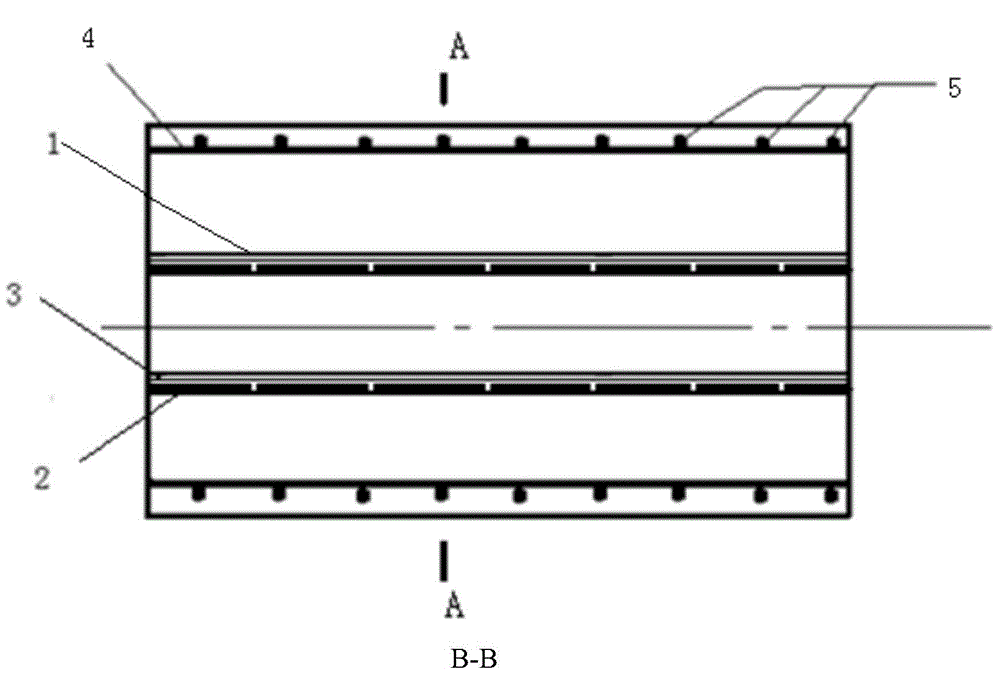

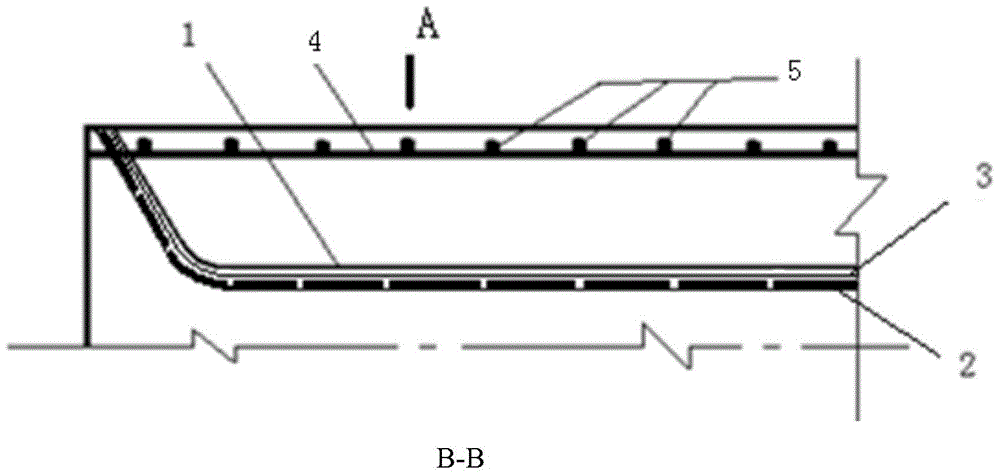

[0044] The width × height × length of the reinforced concrete beam is 0.6 m × 0.9 m × 6.5 m, and both ends of the beam are not visible. Two PVC pipes with a diameter of 30mm are pre-embedded and arranged in the longitudinal direction of the beam as a pre-embedded blast hole. The middle section is parallel to the longitudinal axis of the beam, and the ends are bent upward and open on the upper surface near the end of the beam. The distance between the two blast holes is 0.3m and the distance between the left and right sides of the beam is 0.3m; the upper blasthole is 0.3m from the upper surface of the beam, and the lower blasthole is 0.3m from the lower surface of the beam. The discontinuous charge is adopted, the diameter of the emulsification drug roll is 25mm, the length of the drug roll is 0.2m, and the interval is 0.2m.

[0045] According to the above-mentioned axial embedded blast hole and blast hole charge structure, the construction process of the present invention is:...

Embodiment 3

[0050] The width × height × length of the reinforced concrete beam is 1.4m×2.1 m×6m. Two PVC pipes with a diameter of 32mm are embedded in the longitudinal direction of the beam as embedded blast holes, parallel to the beam axis, and open on the cross section of the beam end. The distance between the two blast holes is 0.7m and the distance between the left and right sides of the beam is 0.7 m; the upper blasthole is 0.7m from the upper surface of the beam, and the lower blasthole is 0.7m from the lower surface of the beam. The continuous charge structure is adopted, and the hole is blocked by gun mud. Adopting a 28mm diameter water gel explosive charging tube with a length of 0.2m.

[0051] According to the above-mentioned axial embedded blast hole and blast hole charge structure, the construction process of the present invention is:

[0052] 1) Destroy the concrete protective layer, find the PVC embedded pipe, and clean the pipe with compressed air;

[0053] 2) Use w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com