Method for producing container bottom cross beam

A production method and bottom beam technology are applied in the directions of feeding devices, positioning devices, storage devices, etc., which can solve problems such as unfavorable environmental protection and low production efficiency, and achieve the effects of reducing labor intensity, improving production efficiency, and avoiding noise pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

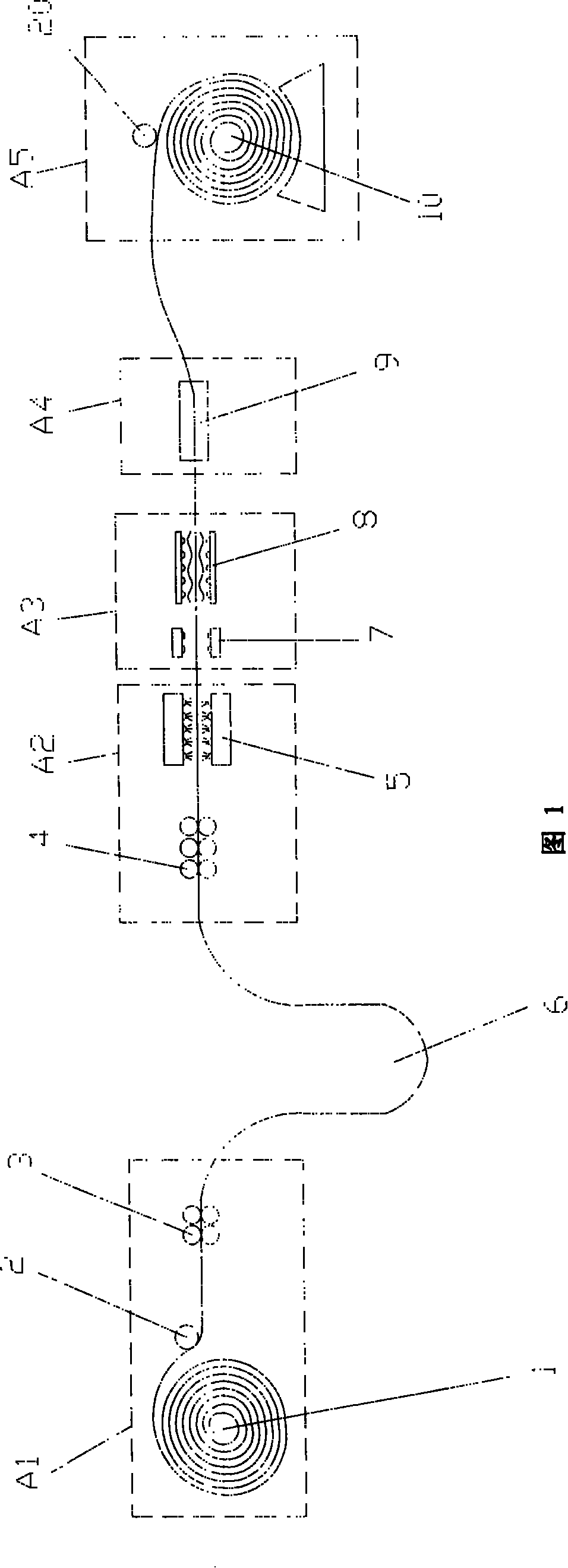

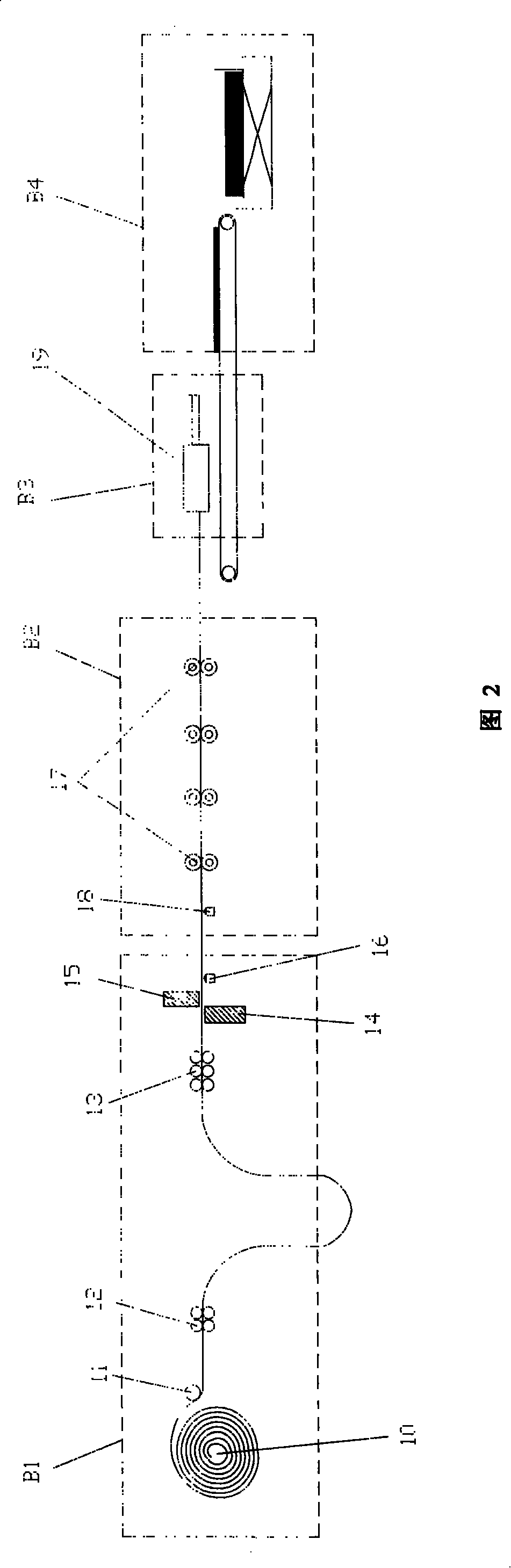

[0035] As shown in Fig. 1 and Fig. 2, in the embodiment of the production method of the container bottom beam of the present invention, it includes a stripping step and a forming step. After the stripping process is completed for the wide coils, multiple rolls of narrow coils are separated, and then each roll of narrow coils is subjected to a forming step to obtain a container bottom beam that meets the requirements.

[0036] As shown in Figure 1, the striping step includes the following steps:

[0037] Uncoiling A1: uncoil the wide coil material (steel coil) 1, press the flat material through the nip roller 2, and then lead out the flat material through the feeding roller 3.

[0038] Sanding A2: The sheet is sent to the leveling machine 4 for leveling, and the leveled sheet is continuously sent to the sanding machine 5 to sand the upper and lower surfaces of the sheet.

[0039] A loop pit 6 is provided between the leveler 4 and the feed roller 3 for absorbing the asynchronou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com