Method for shaping container bottom cross beam and preparing method

A production method and a molding method technology, which are applied in the directions of feeding devices, positioning devices, storage devices, etc., can solve problems such as low production efficiency, and achieve the effects of improving production efficiency, reducing production costs, and reducing labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

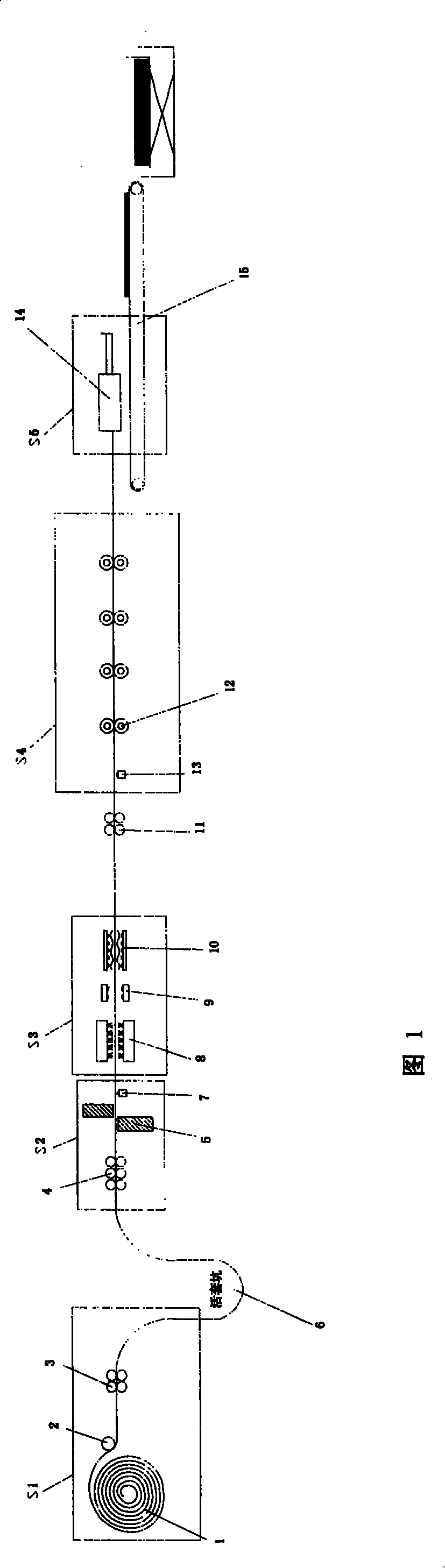

[0036] As shown in Figure 1, in the embodiment of the production method of the container bottom beam of the present invention, comprise the following steps:

[0037] Uncoiling S1: Uncoil the coil material 1 that meets the width requirements, press the flat material through the nip roller 2, and then lead out the material through the feeding roller 3. The coil 1 can be divided into narrow coils by a slitting machine. The width of the roll material 1 can be divided into strips according to the requirements of the actual container.

[0038] Pretreatment S2: Introduce the blank to the pretreatment equipment for pretreatment. The pretreatment includes roughly leveling the uncoiled sheet through the leveler 4; cutting the initial section of the sheet through the cutting machine 5; when the two coils are connected, welding, Steps such as connecting two rolls of coil material. In this embodiment, the sheet material is driven by the feeding roller 3 into the leveling machine 4 for l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com