Vacuum emulsifying device for cosmetic production

A technology of vacuum emulsification and cosmetics, applied in mixers with rotating stirring devices, transportation and packaging, chemical instruments and methods, etc., can solve problems such as inconsistent feeding, emulsifier addition, product specification deviation, etc., and achieve the dosage ratio Precise, slowing effect of flow velocity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

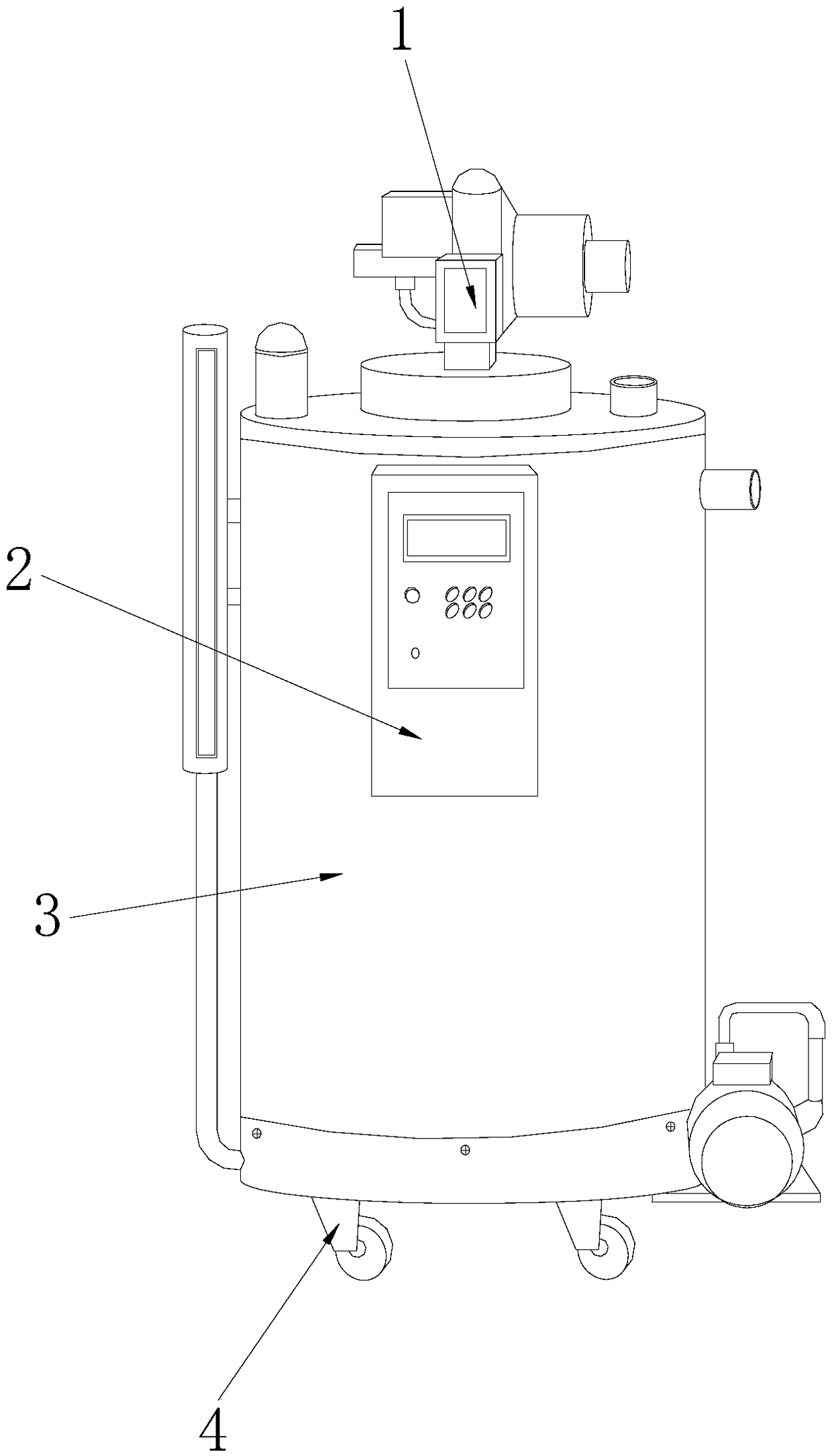

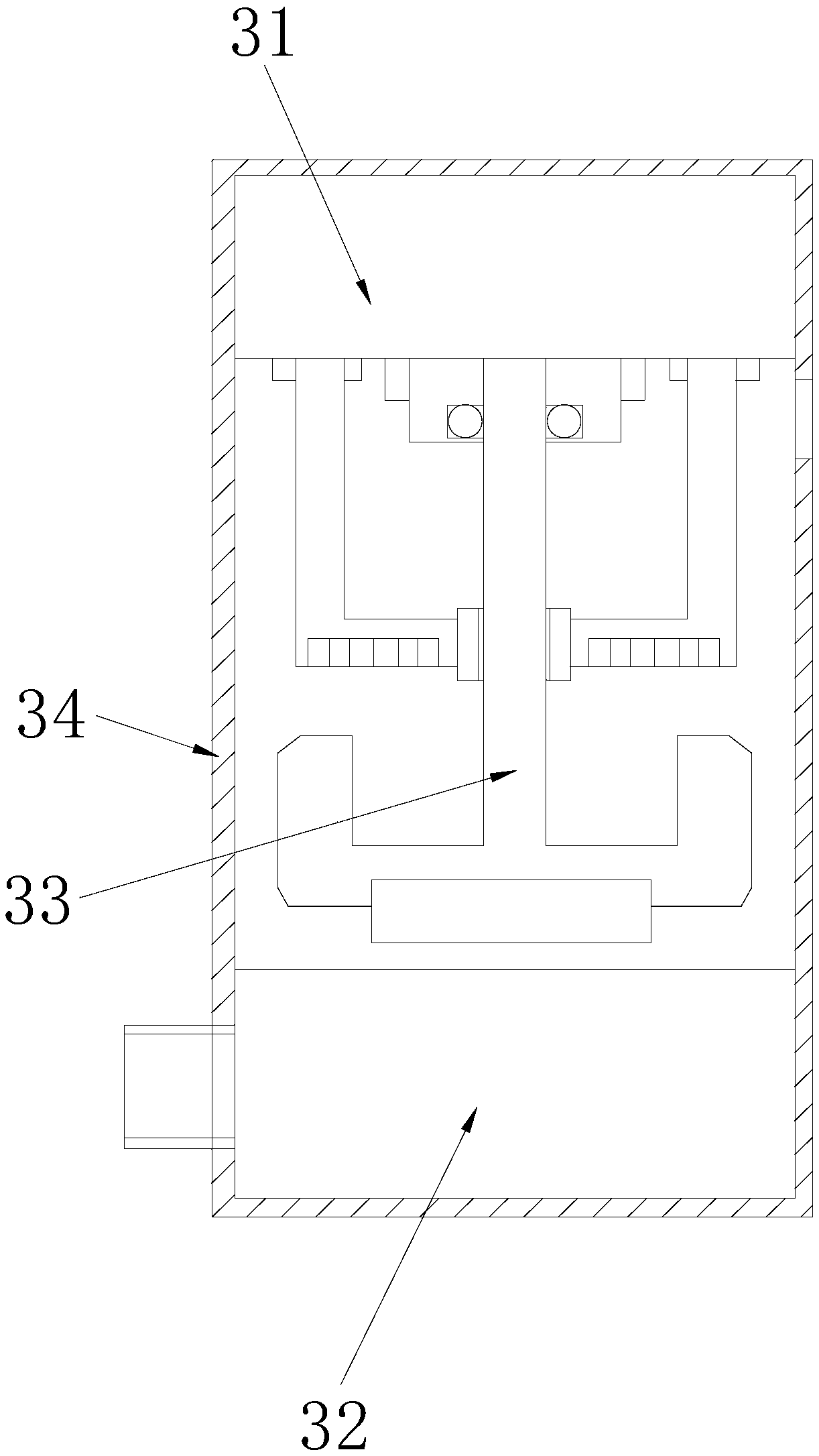

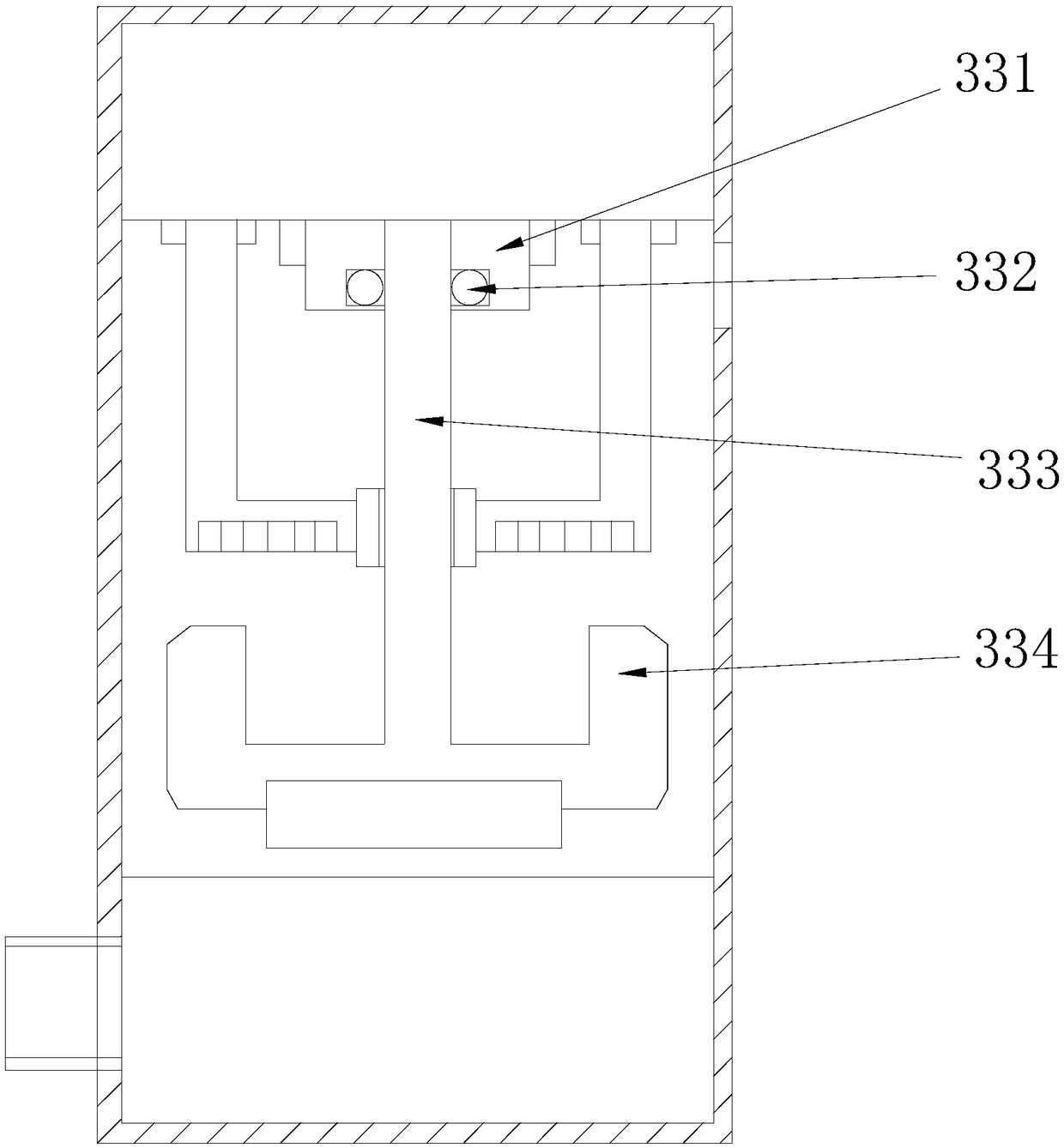

[0027] see Figure 1-Figure 8, the present invention provides a vacuum emulsification device for the production of cosmetics, its structure includes a motor 1, a controller 2, a tank body 3, and a roller 4, the bottom end of the motor 1 is welded to the top end of the tank body 3, and the The controller 2 is arranged at the front end of the tank body 3, and the top end of the roller 4 is welded to the bottom end of the tank body 3. The tank body 3 includes a liquid filling mechanism 31, a liquid discharge mechanism 32, a stirring mechanism 33, and a casing 34. The top of the liquid adding mechanism 31 is welded to the top of the shell 34, the bottom of the liquid discharge mechanism 32 is welded to the bottom of the shell 34, and the top of the stirring mechanism 33 is vertically embedded in the bottom of the liquid adding mechanism 31 In the middle of the end, the stirring mechanism 33 is located directly above the liquid discharge mechanism 32. The liquid addition mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com