Parallel pipe liquid-cooling radiator for heat dissipation of high-power IGBT

A high-power, radiator technology, applied in the direction of circuits, electric solid-state devices, semiconductor devices, etc., can solve the problems of device damage, unbalanced heat transfer efficiency, poor heat transfer effect of IGBT devices, etc., to achieve convenient maintenance and prolong conduction and heat conduction Time, the effect of improving heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

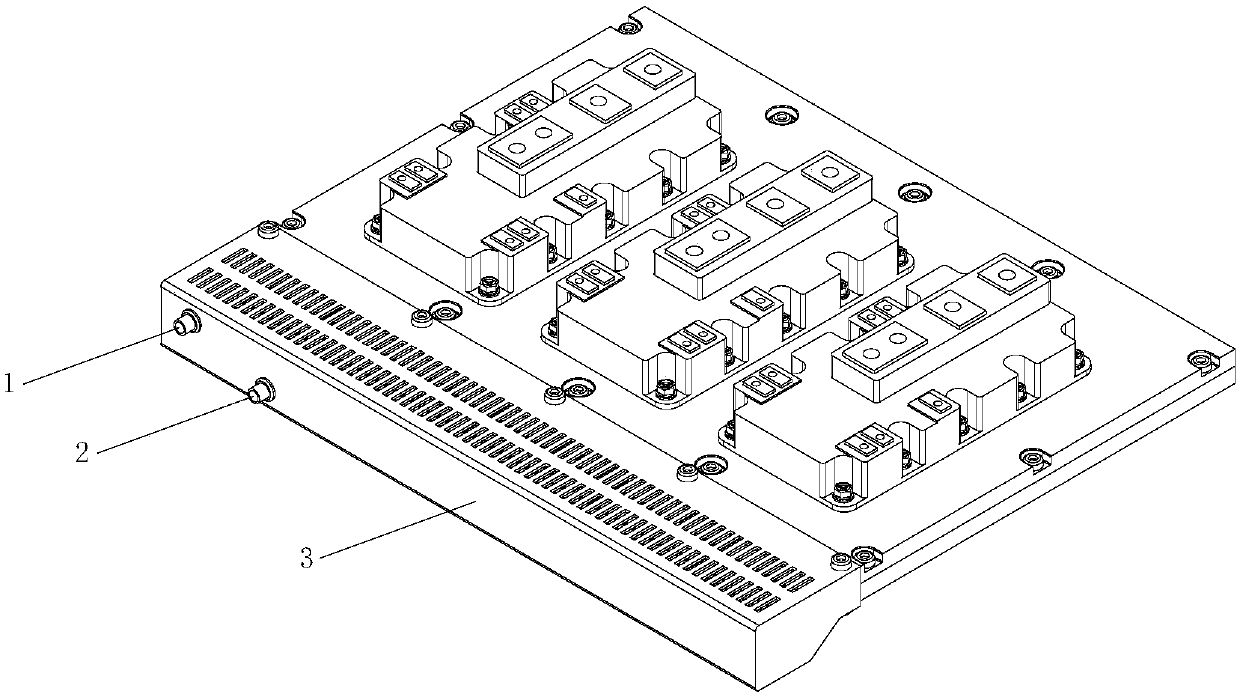

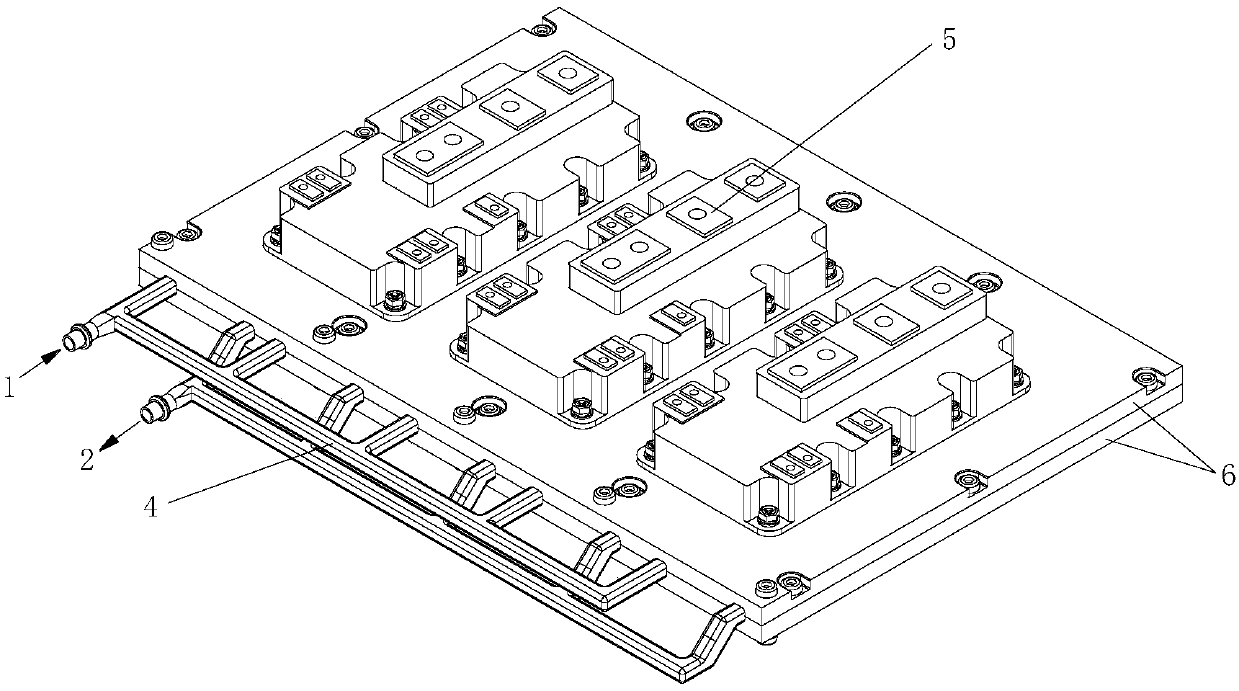

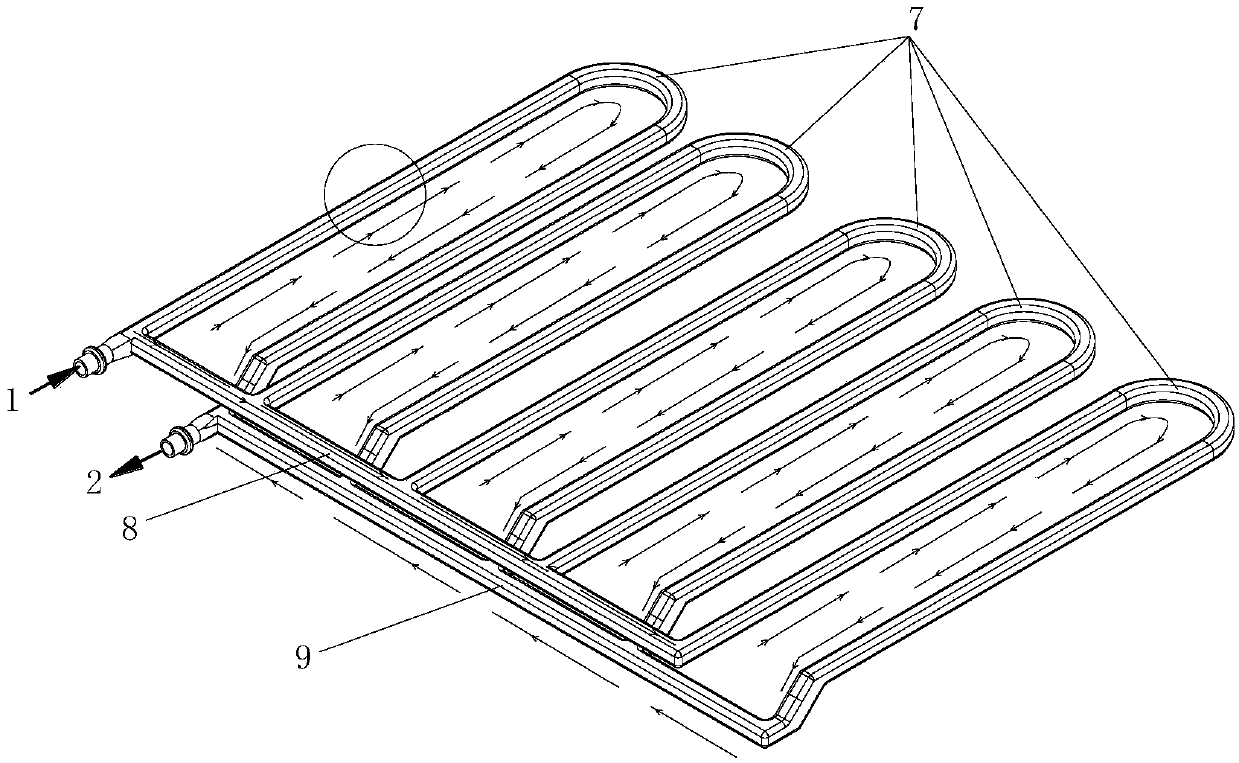

[0029] Such as figure 1 and Figure 5 As shown, a parallel pipeline liquid cooling radiator for high-power IGBT heat dissipation includes two aluminum plates 6 and a composite copper tube 4; the two aluminum plates 6 are stacked, and the composite copper tube 4 is embedded in the laminated aluminum plate In the middle of 6, each aluminum plate 6 is provided with a groove 11 corresponding to the composite copper pipe 4. The structures of the grooves 11 of the two aluminum plates 6 can be completely the same or different, as long as they can accommodate the composite copper tube after being stacked.

[0030] Preferably, the composite copper tube 4 is circular, and the cross section of the groove 11 opened by each aluminum plate 6 is a corresponding semicircle.

[0031] Preferably, the composite copper tube 4 and the two aluminum plates 6 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com