VOC waste gas efficient purifying furnace with electric heating wires conveniently replaced

A heating wire and purification furnace technology, applied in incinerators, lighting and heating equipment, combustion methods, etc., can solve the problems of insufficient combustion, short exhaust gas residence time, and large material loss, so as to prolong life and improve purification. effect, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

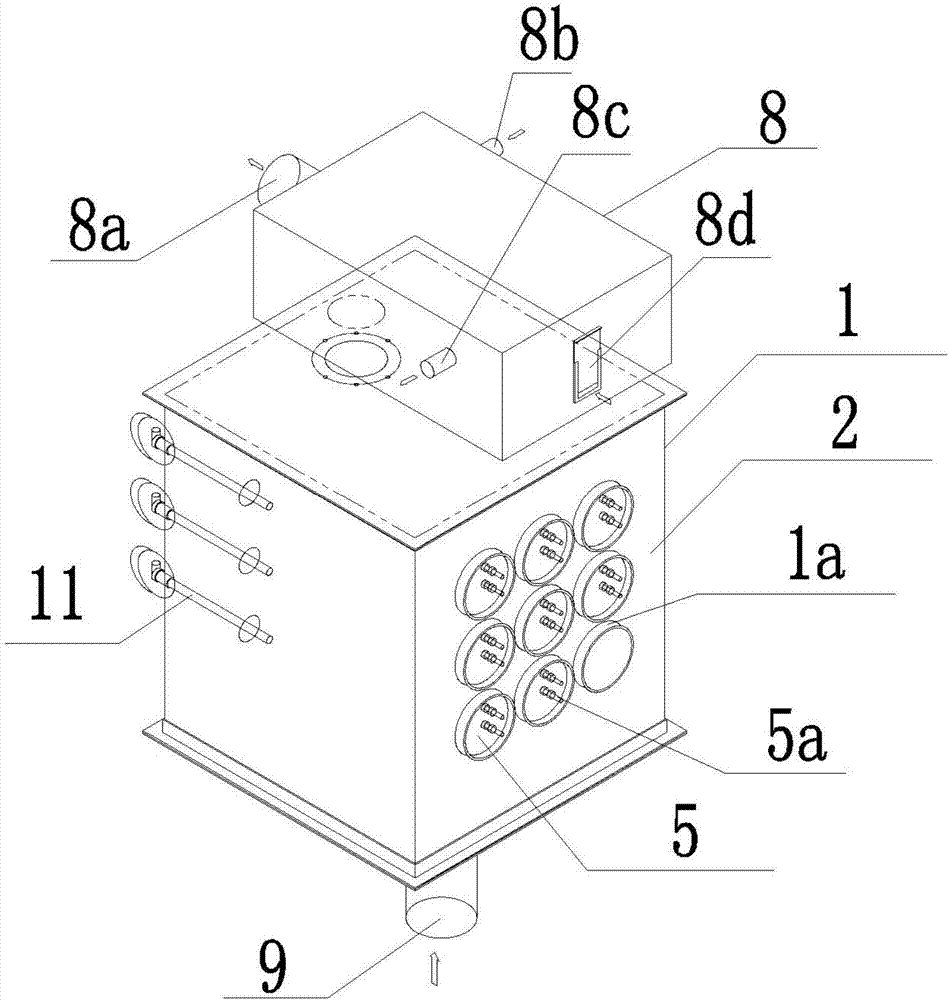

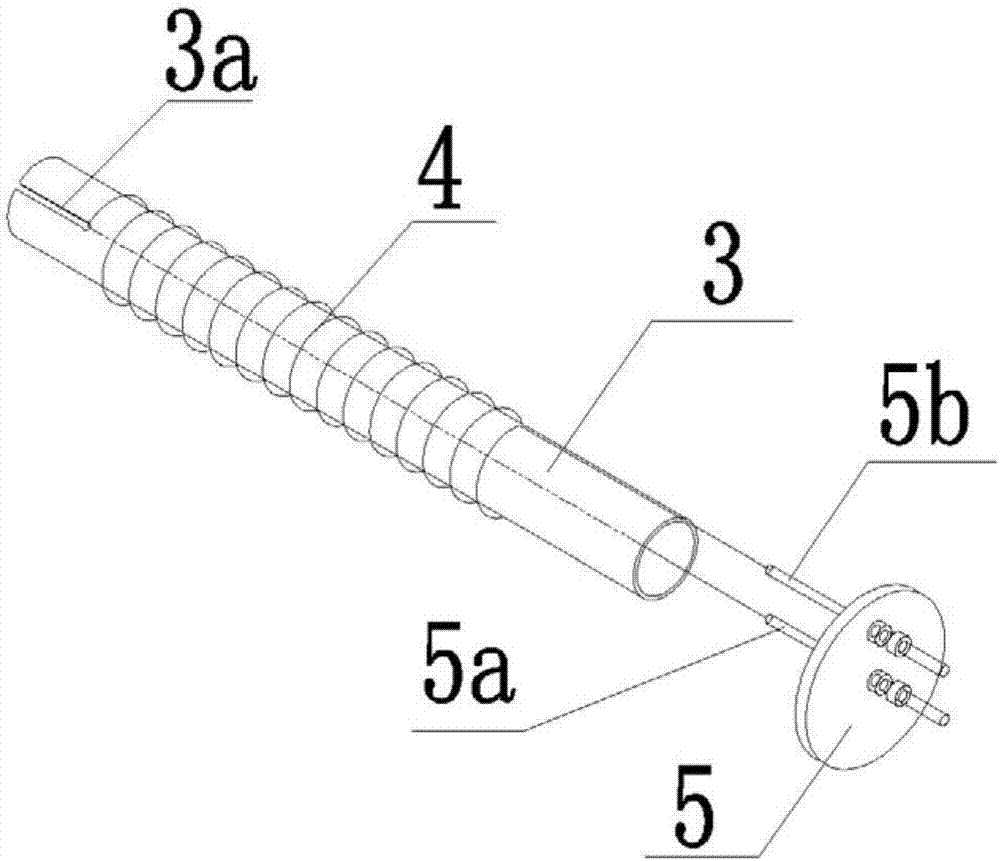

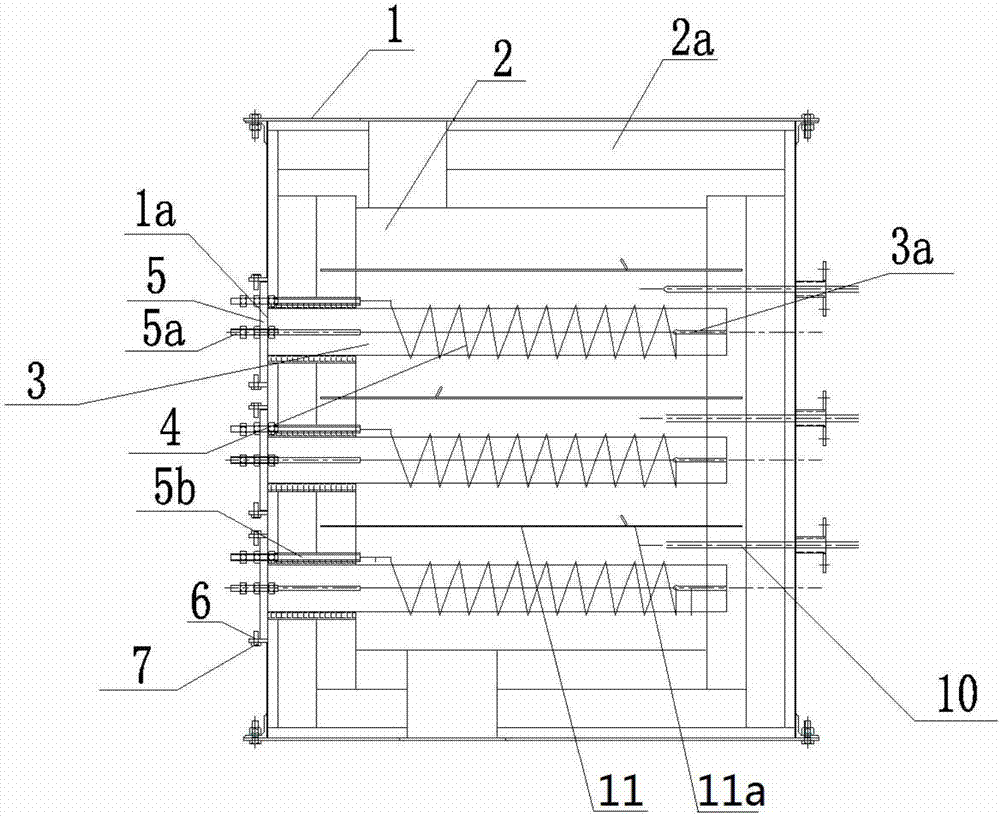

[0027] combine figure 1 , figure 2 and image 3 Shown is a specific embodiment of a VOC waste gas high-efficiency purification furnace that facilitates the replacement of heating wires according to the present invention. The furnace 2 also includes a heating assembly arranged in the furnace 2 and a driving power source electrically connected to the heating assembly. A condenser 8 with an air outlet 8a is arranged on the top of the furnace body, and an air inlet 9 is arranged at the bottom, and the condenser 8 is also respectively provided with a water inlet pipe 8b, a water outlet pipe 8c and an air inlet 8d; The side wall of the shell 1 is provided with nine assembling holes 1a distributed at intervals, and each assembling hole 1a is equiangularly distributed around the assembling hole 1a in the center of the side wall of the furnace shell 1, and is divided into three rows. Three in each row; further, a heating assembly is inserted into each assembly hole 1a, and a cerami...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com