One group of double-turbulence loop reactor

A loop reactor and pipe section technology is applied in the field of unit groups of double-disturbance loop reactors, and achieves the effects of overcoming large equipment investment, large economic benefits, and enlarging the scope of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the embodiments shown in the accompanying drawings.

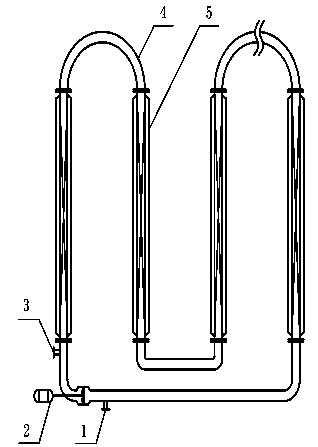

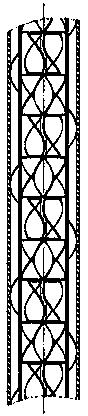

[0021] The double disturbance loop reactor of the present invention comprises a fluid inlet 1, an axial flow circulation pump 2, a fluid outlet 3, an elbow 4, and a jacketed loop reactor pipe section 5, and the inner pipe of the loop reactor pipe section is arranged for static mixing Disturbance element, the flow disturbance element is arranged in the jacket of the pipe section of the loop reactor. The turbulence element in the pipe is a columnar, sheet, curved, ribbon, and helical static mixing element that can play a role in turbulence. The internal disturbance element of the jacket is a spiral plate type, a spoiler column type and a combination thereof.

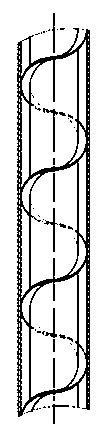

[0022] The inner tube of the jacketed loop reactor section 5 is equipped with a single-tube four-rotation static mixing and disturbing element ( figure 2 ), the helical vane spoiler el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com