A Numerical Simulation Method for Parameter Design of Axisymmetric Jet Plenum

A technology of parameter design and numerical simulation, applied in the field of high-pressure gas lubrication, which can solve the problem of rare jet pressure chamber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0087] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

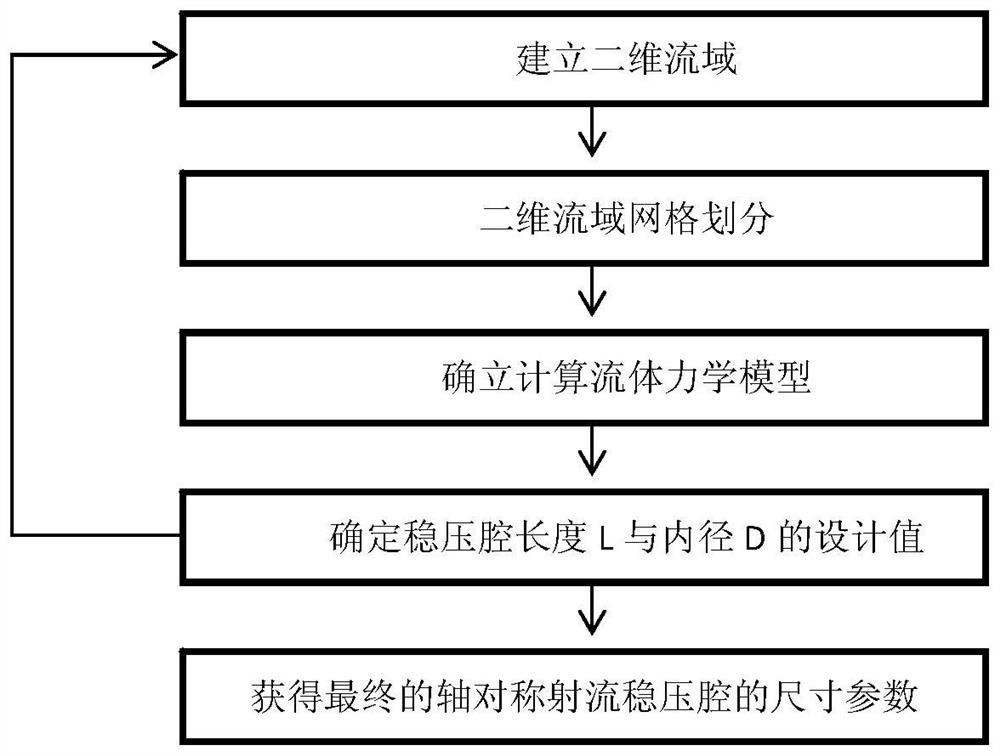

[0088] A numerical simulation method for parameter design of an axisymmetric jet plenum, such as figure 1 As shown, it is mainly realized by the following steps:

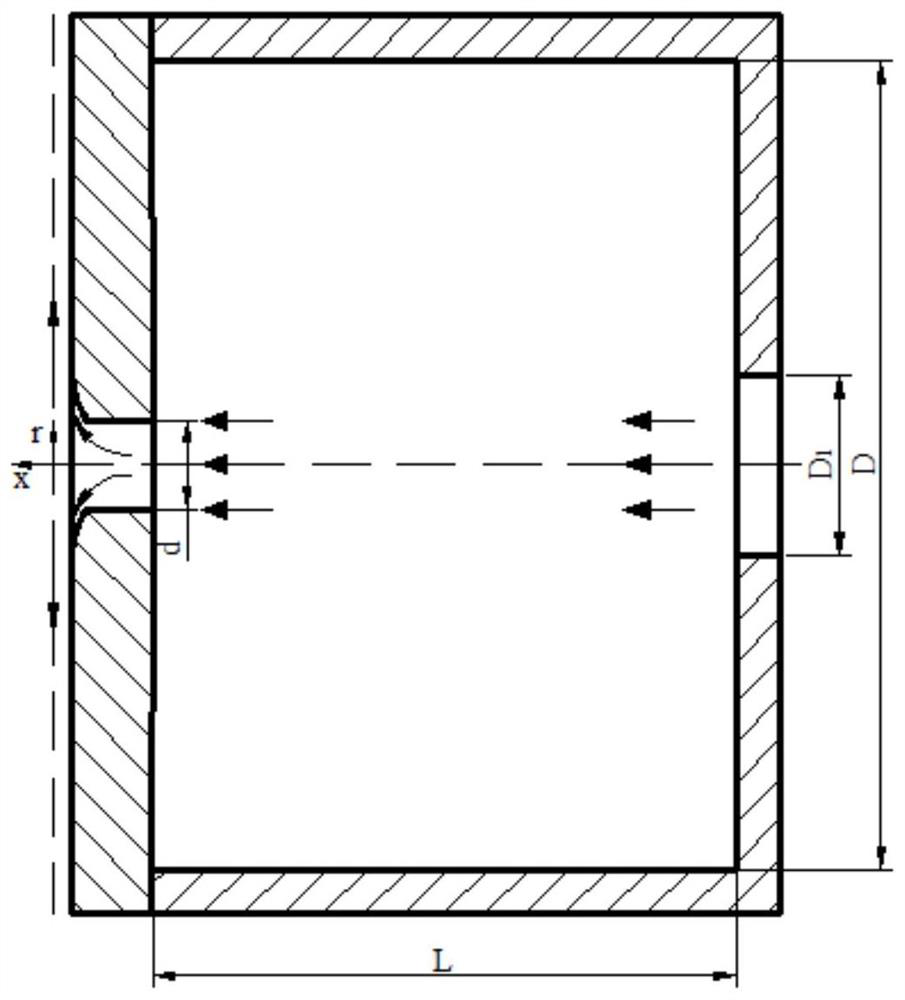

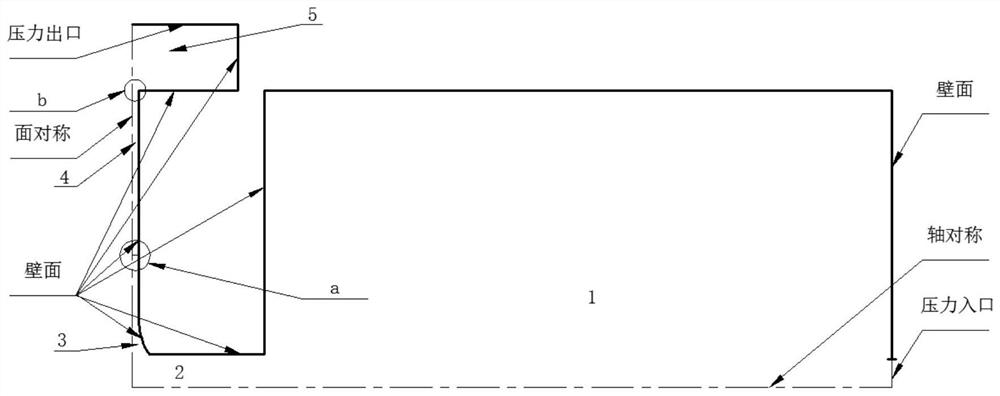

[0089] Step 1: Build a Physical Model

[0090] Such as figure 2 As shown, drawing the geometric model of the axisymmetric jet plenum needs to determine four dimensional parameters: the length of the plenum, the inner diameter of the plenum, and the diameter of the inlet of the plenum D. 1 And the outlet diameter of the plenum chamber d. The axisymmetric jet flow stabilizing chamber is used in conjunction with the high-pressure disc gas bearing with double symmetrical shrinkage sections. The design mass flow rate of the bearing is q max (The maximum mass flow q that can pass max ) and the outlet diameter d of the plenum chamber (that is, the diameter of the beari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com