Slide limiting differential mechanism with asymmetric structure

A technology of limited-slip differential and asymmetric structure, which is applied in the direction of differential transmission, belt/chain/gear, mechanical equipment, etc., and can solve the problems of difficult surface strengthening treatment, inconvenient processing, high manufacturing cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

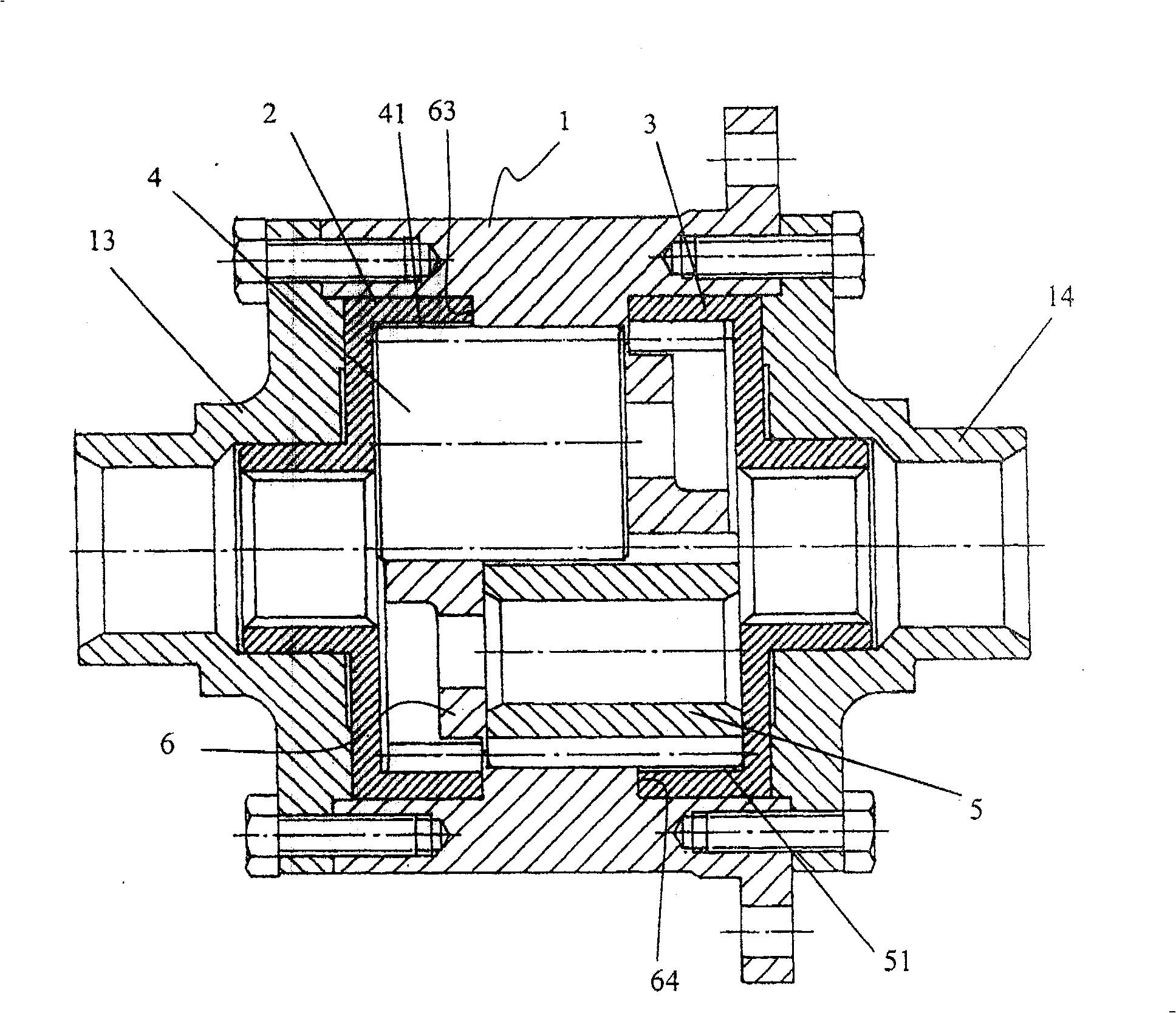

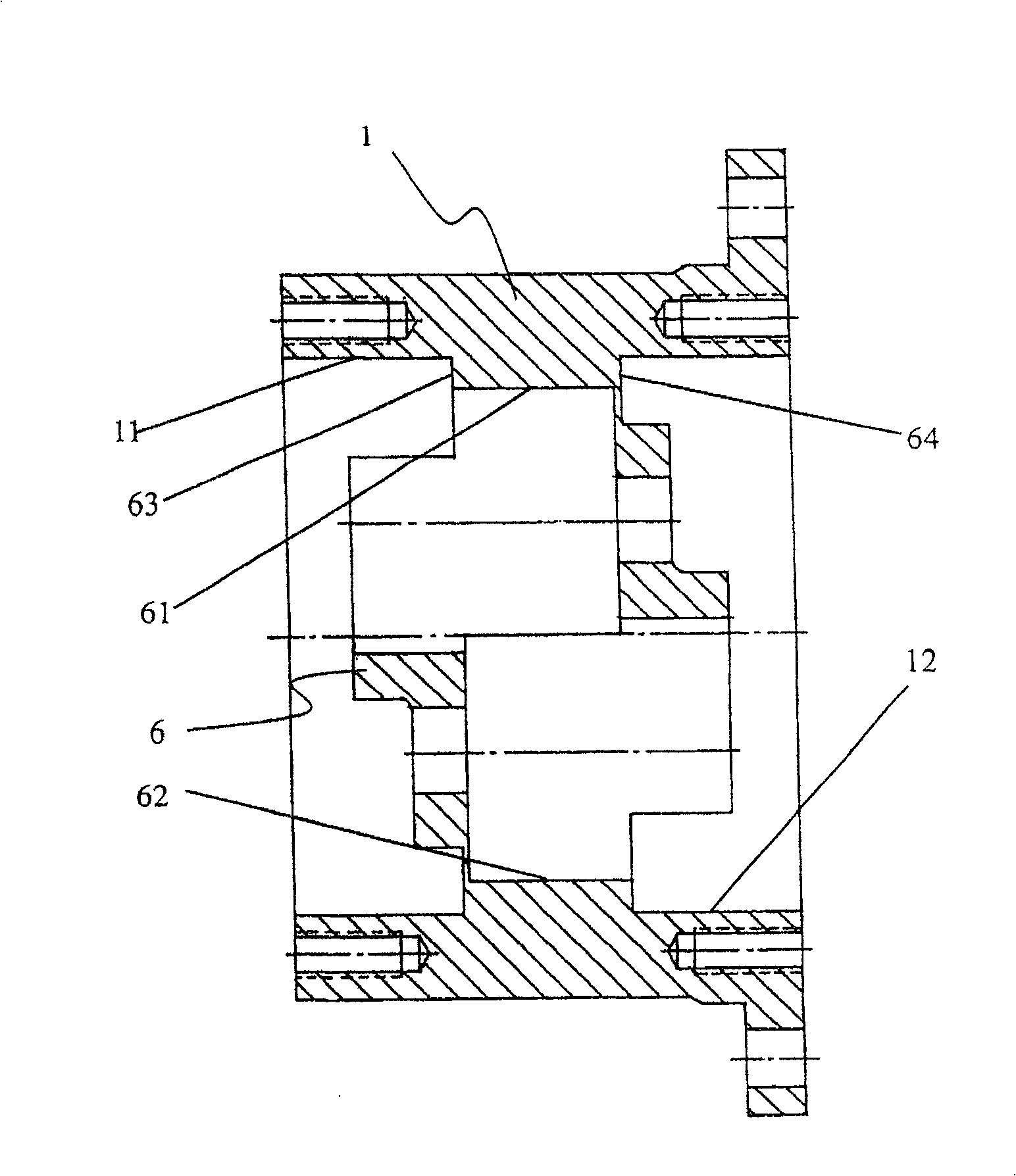

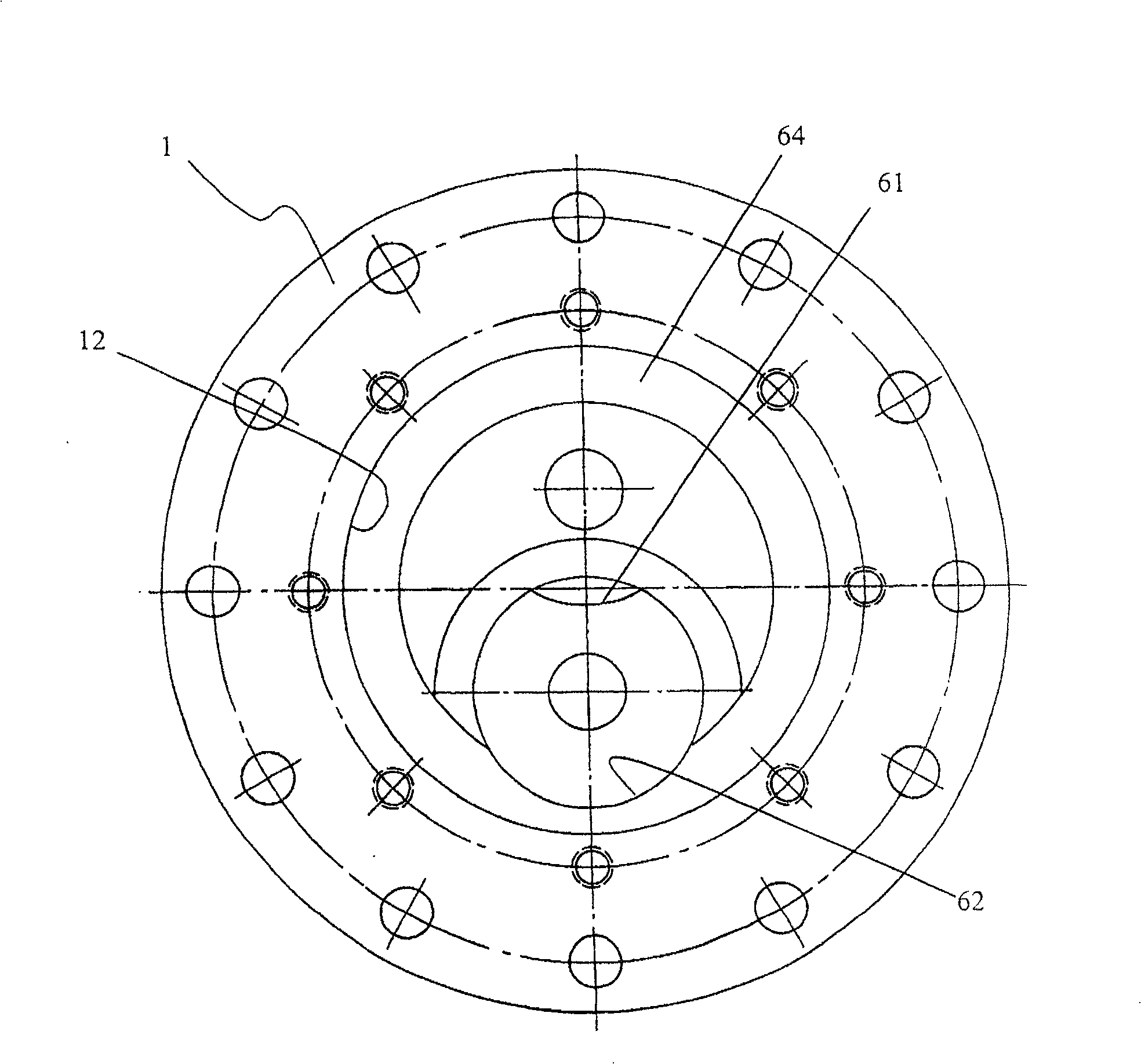

[0035] like Figure 1-7 As shown, the present invention is applicable to the asymmetric structure limited-slip differential between the drive wheel and the drive axle, which includes a differential case 1 and is fixed in the differential case 1 to the planetary gear 4 and 5 planetary carrier 6 which transmits the input torque and maintains its position;

[0036] A first side internal gear 2 and a second side internal gear 3, which are arranged at the first end and the second end in the differential case 1, as two power output ends of the differential;

[0037] A first-side planetary gear 4 and a second-side planetary gear 5 are provided on the planetary carrier 6 inside the differential case 1 and meshed with each other, wherein the first-side internal gear 2 is only connected to the first-side The planetary gear 4 is meshed, and the second-side internal gear 3 is only meshed with the second-side planetary gear 5;

[0038] A first inner hole 61 is formed on the planet carrie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com