A core structure optimization method for plate-fin heat exchanger based on dynamic pixel granularity

A technology of plate-fin heat exchanger and optimization method, which is applied in instruments, special data processing applications, electrical digital data processing, etc., can solve the problems of difficult to meet the requirements of design accuracy, strong local optimization ability, and poor global search ability. , to achieve the effect of improving local search efficiency, enhancing global search capability, and expanding search range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0041] 1.1 Problem Description

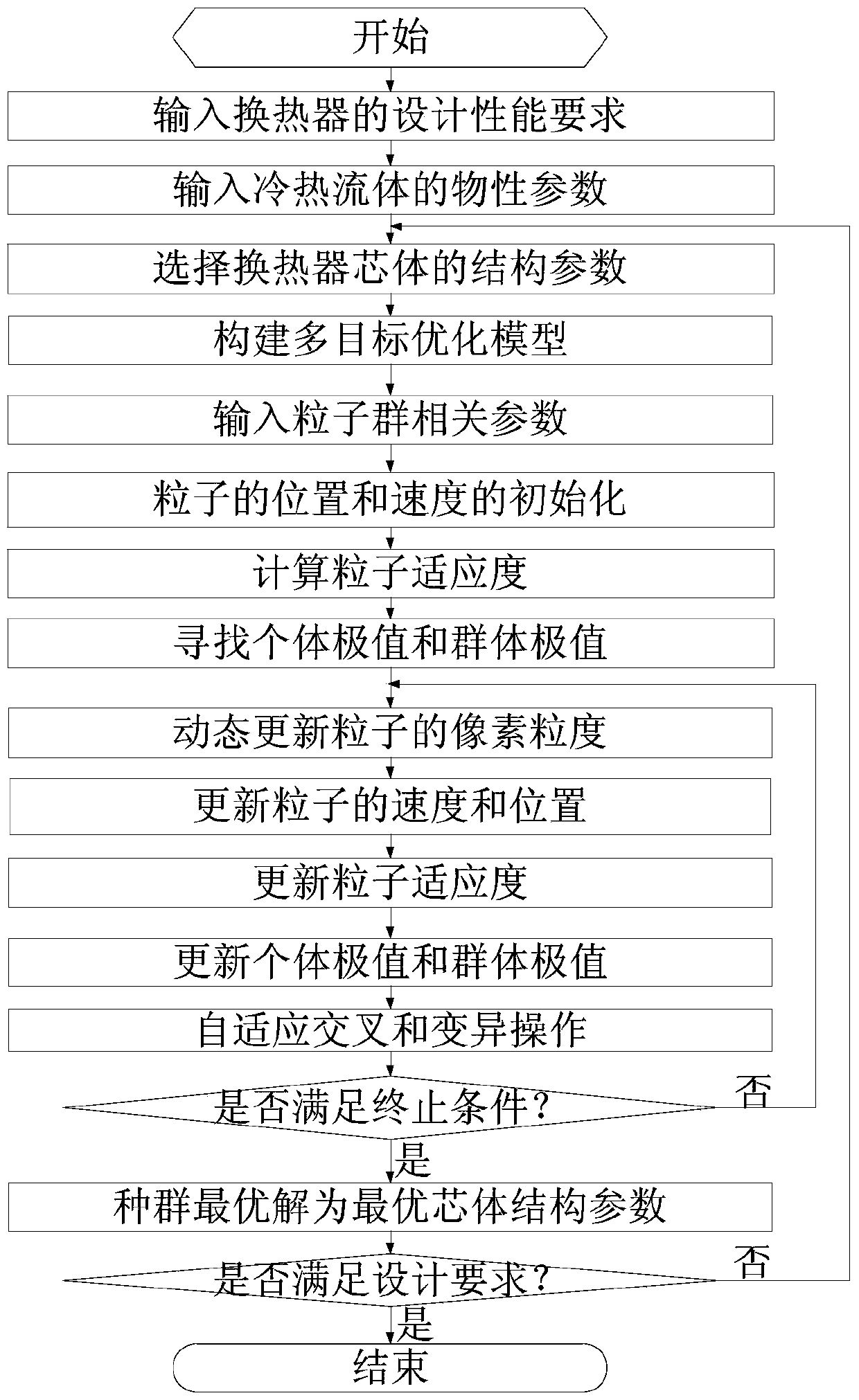

[0042] There are two design requirements for heat exchanger design: one is to reduce the overall size and weight of the heat exchanger as much as possible while meeting the set efficiency and resistance requirements. The other is to make the heat exchanger as efficient as possible given the size and weight requirements of the heat exchanger. The present invention aims at reducing the weight of the core body, and selects the optimization parameters. The overall process of optimizing the core body structure of the plate-fin heat exchanger based on the dynamic pixel granularity of the present invention is as follows: figure 1 shown.

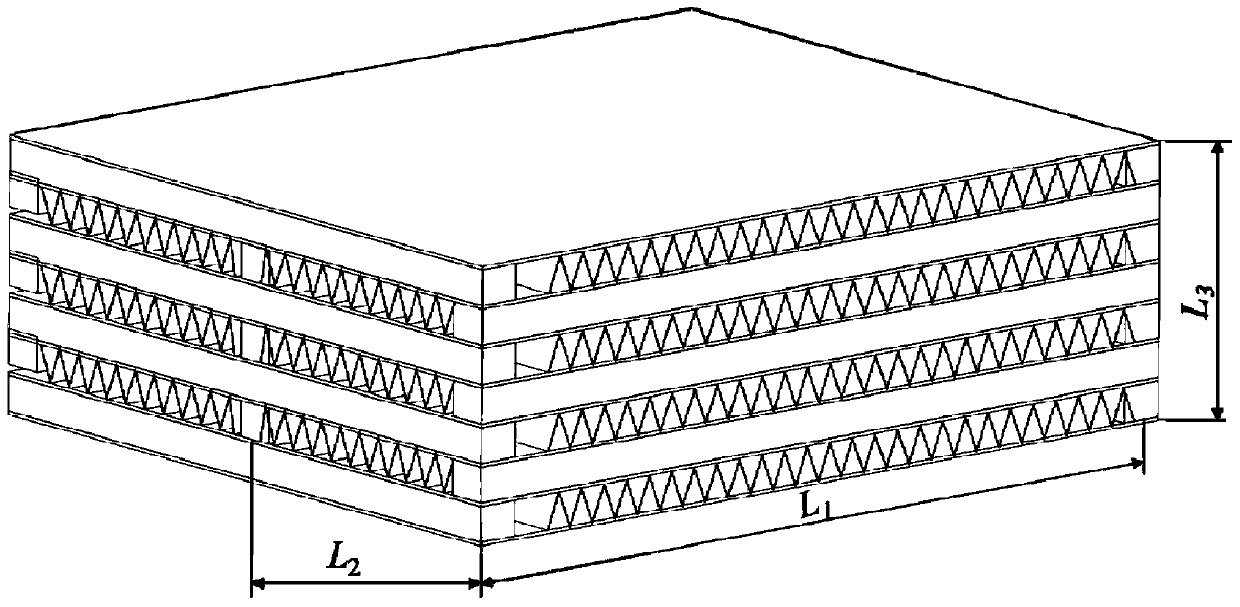

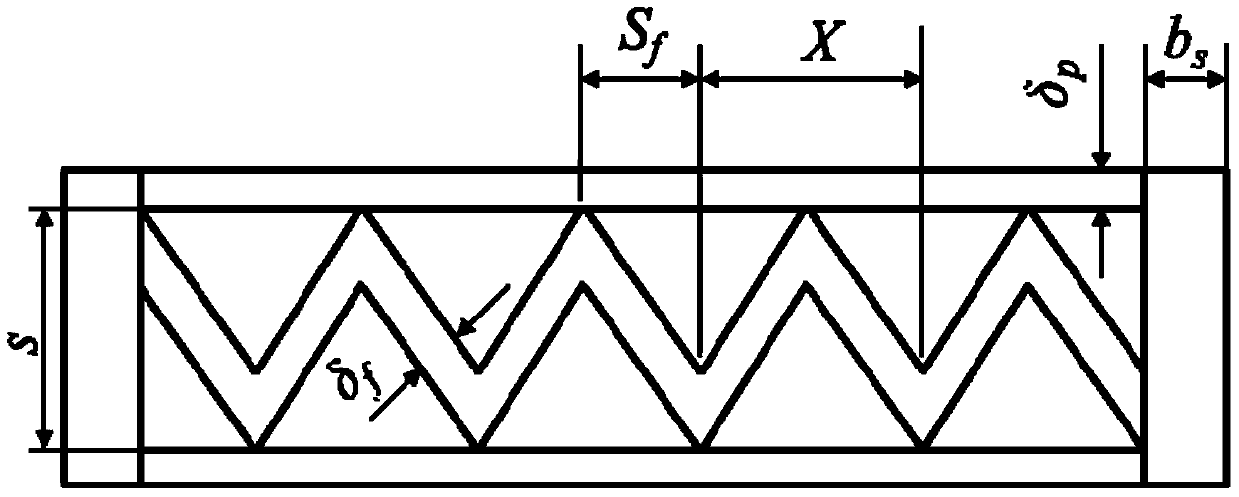

[0043] The plate-fin heat exchanger is composed of plate bundles, heads, connecting pipes and supports, etc., and the part composed of multiple rows of plate bundles is the core. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com