Composite unit for bone implant, porous support and preparation method

A technology of bone implants and porous scaffolds, which is applied in the fields of bone implants, medical science, prostheses, etc., can solve the problems of less implant design and only consider uniaxial load, so as to shorten the design time, The effect of simple structure and improved resistance to bending deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

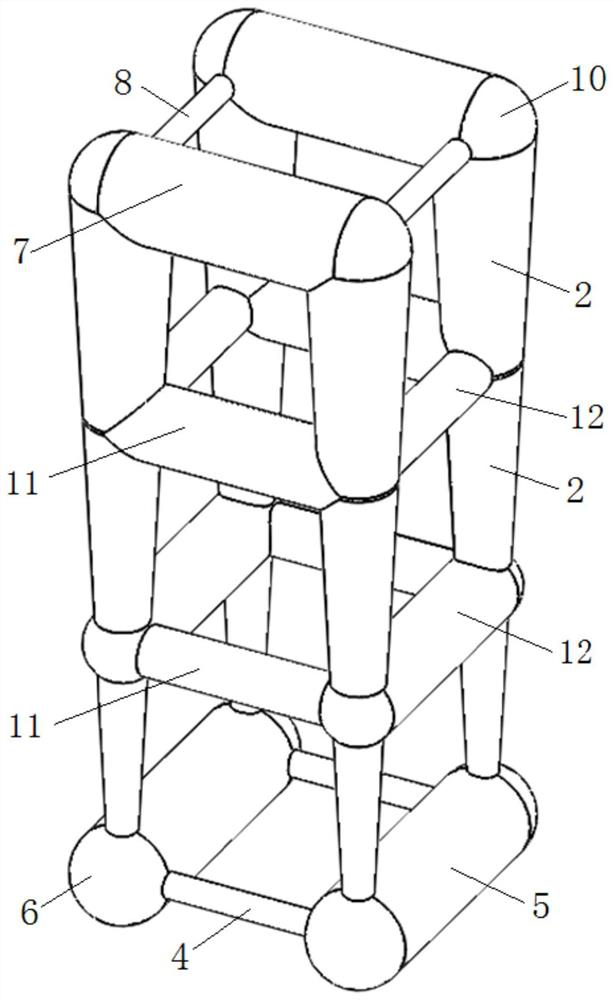

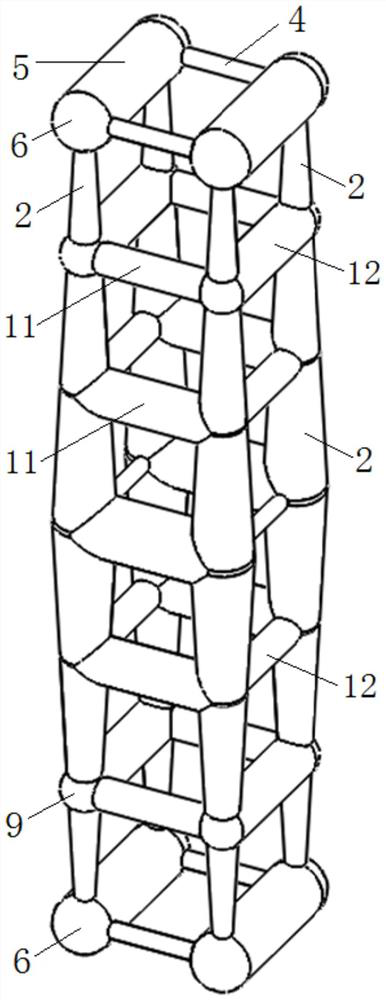

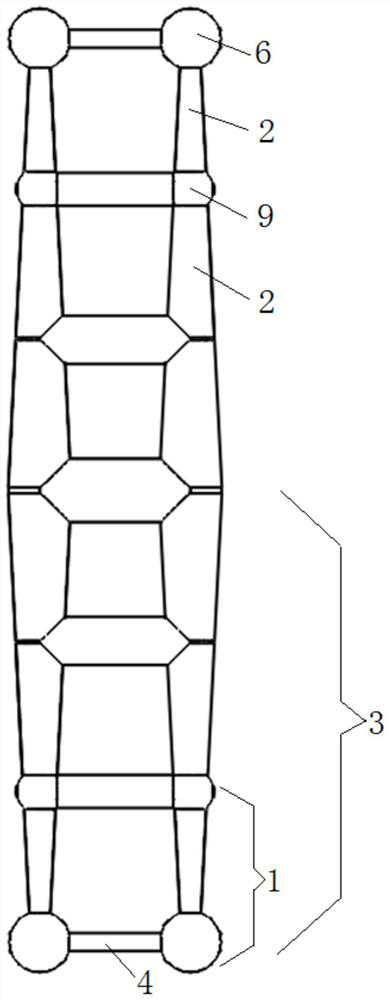

[0033] Such as figure 1 - As shown in 4, a composite unit for bone implants, including several structural units 1, the structural unit 1 includes a first receiving surface, a second receiving surface and a conical connecting rod 2, a plurality of One end of the connecting rod 2 is respectively connected to the first receiving surface, and the other ends of the plurality of connecting rods 2 are respectively connected to the second receiving surface, and the radius of one end surface of the connecting rod 2 is smaller than the radius of the other end surface thereof, The structural units 1 are sequentially merged to form a porous structure 3, that is, the second receiving surface and the first receiving surface of the adjacent structural unit 1 are sequentially merged to form a porous structure 3, and the radius of the two ends of the connecting rod 2 Incrementing along the head end to the tail end of the porous structure 3, the second bearing surfaces at the end ends of the tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com