Exhaust system mixer

An exhaust system and mixer technology, applied in the direction of exhaust devices, machines/engines, mechanical equipment, etc., can solve the problems of reducing the overall flow rate of the gas, reducing the exhaust effect of the exhaust system, and different, so as to improve the flow speed, The effect of improving the use value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

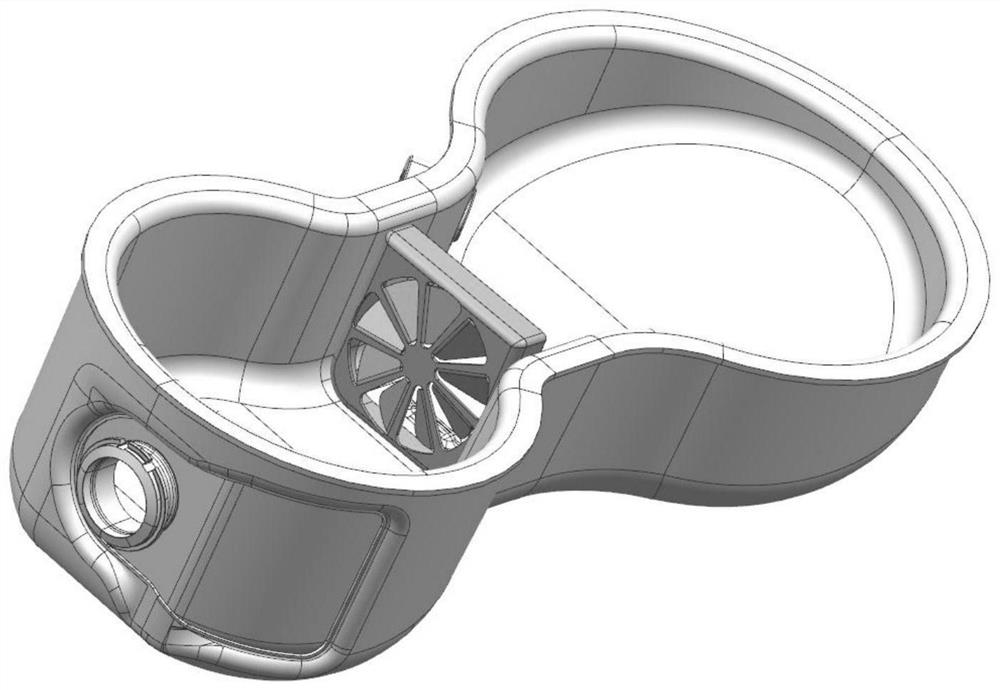

[0030] Such as figure 1 As shown, the exhaust system mixer of the present invention includes a casing 1, and the inner walls of both sides of the casing 1 in the middle are fixedly connected with the same mounting bracket 9, and the inner wall of the mounting frame 9 is fixedly connected with a fan-shaped mixer body 4, and the mounting frame 9 The outer wall close to the fan-shaped mixer body 4 is fixedly connected with the flow limiting frame 10, the outer wall of one side of the shell 1 is provided with an air intake hole, and the inner wall of the air intake hole is fixedly connected with the air intake pipe 2, and the outer wall of the other side of the shell 1 is opened with a exhaust hole, and the inner wall of the exhaust hole is fixedly connected with an exhaust pipe 6.

[0031] In this embodiment, the fan-shaped mixer body 4 is used to replace the square mixer, and the gas entering the housing 1 through the air inlet pipe 2 enters the other side of the mounting frame ...

Embodiment 2

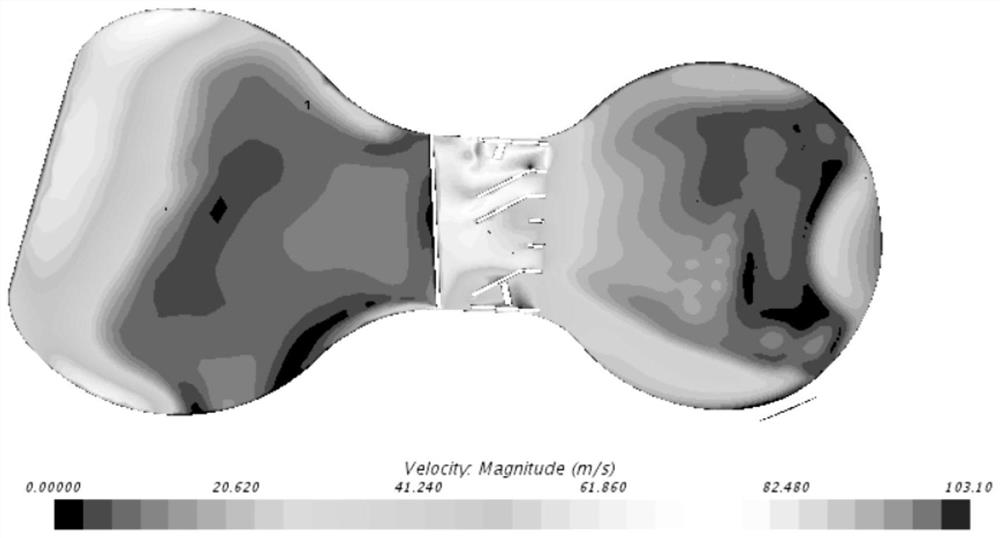

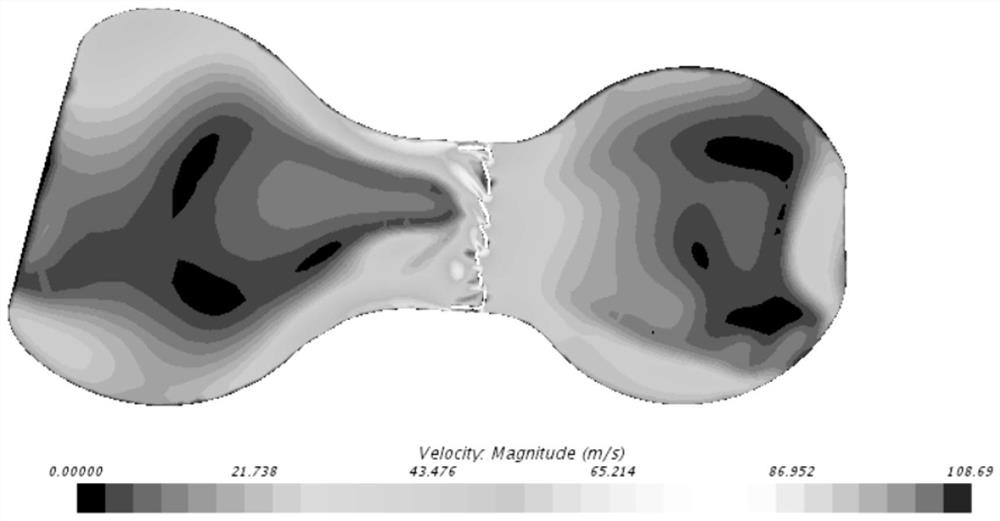

[0034] Such as Figure 4 to Figure 8 As shown, this embodiment is an improvement of Embodiment 1. On the basis of Embodiment 1, this embodiment adds a flow guide assembly, an equal distribution assembly, and a preliminary purification assembly in the housing 1, so that the incoming air flow first passes through the guide flow assembly, and then pass through the equal distribution assembly, so that the gas flowing to the fan mixer body 4 passes through each fan blade on the fan mixer body 4 evenly, and the existence of the fan blade makes the gas flow through the fan mixer body 4 , the gas flows out at an oblique angle, so that there is a dislocation impact with the airflow at the other end of the fan-shaped mixer body 4, avoiding a direct impact that causes a greatly reduced flow rate, thereby increasing the gas flow rate and improving the use value of the fan-shaped mixer body 4

[0035] refer to Figure 4 and Figure 5 , the guide assembly includes a tapered guide rod 11, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com