Card edge connector and manufacturing method thereof

A card edge connector and manufacturing method technology, applied in the direction of contact manufacturing, connection, contact parts, etc., can solve the problem that the oxide layer is not easy to be scraped off, affects the effect of scraping and electrical connection, and the chips are easy to accumulate on the metal. Problems such as the surface of contacts and terminals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0106] The terminal structure of the card edge connector provided by the present invention can be widely used in various connectors with transmission terminals, and because the combinations of terminals are too numerous to enumerate, the manufacturing method of the card edge connector provided by the present invention It can be implemented according to various connectors, so it is not repeated here, and only preferred embodiments are listed for specific description.

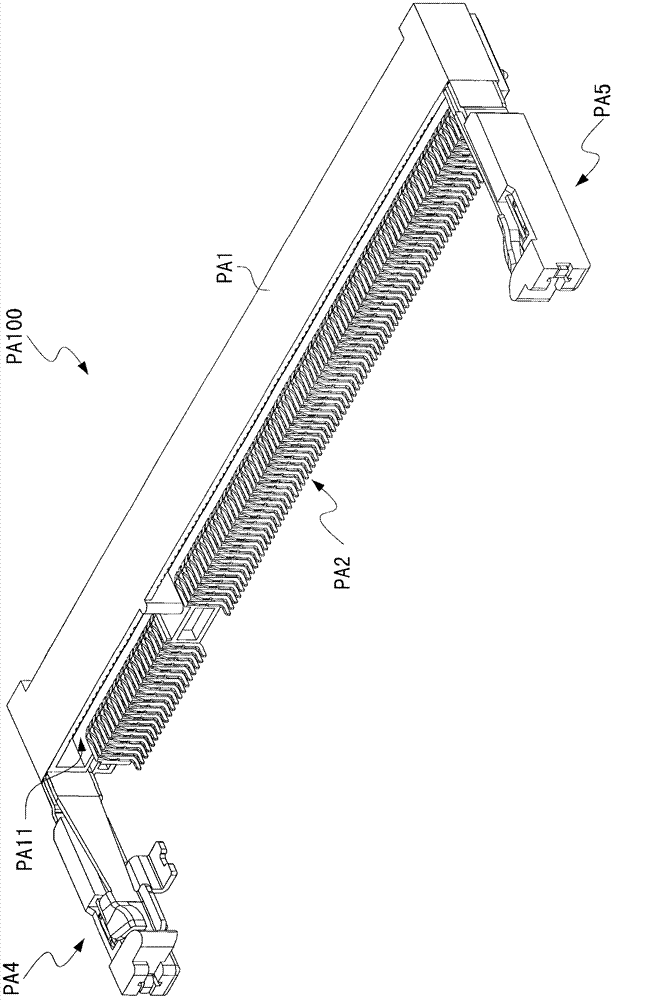

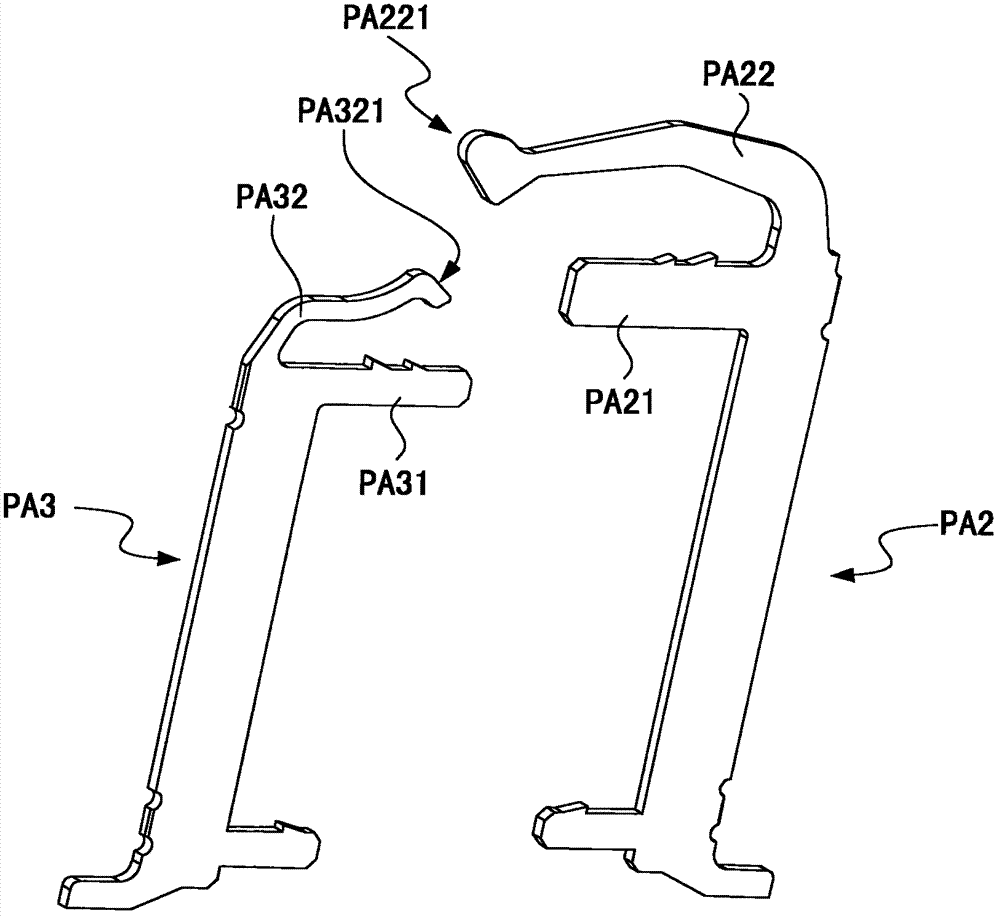

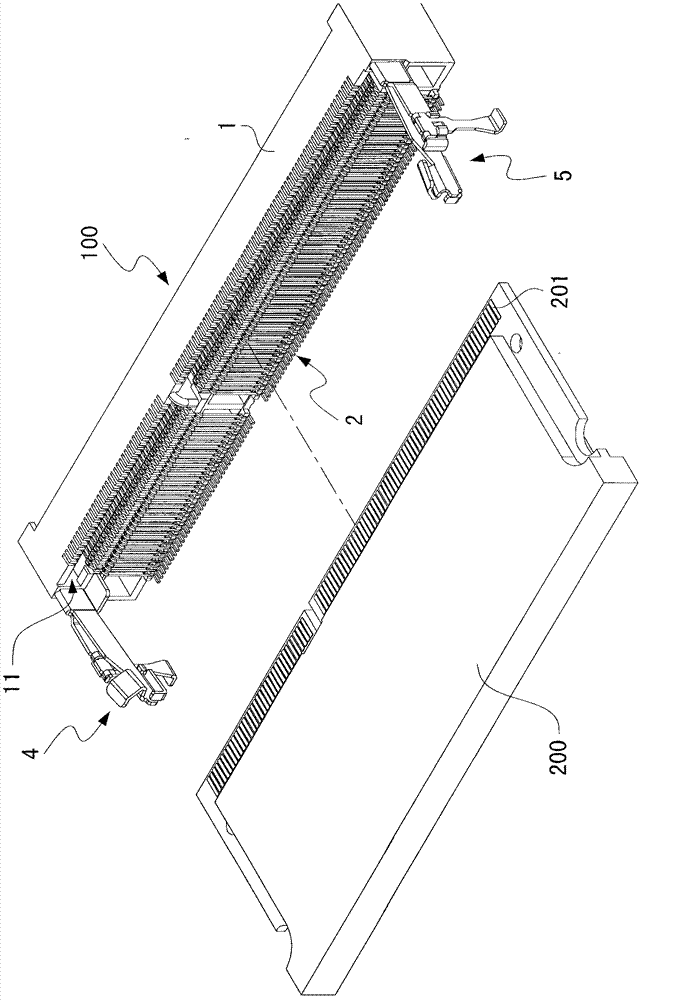

[0107] see image 3 and Figure 4 , image 3 A schematic perspective view showing a card edge connector according to a preferred embodiment of the present invention; Figure 4 A three-dimensional exploded schematic diagram showing a preferred embodiment of the card edge connector of the present invention. As shown in the figure, a card edge connector 100 includes an insulating body 1 , a plurality of first terminals 2 , a plurality of second terminals 3 and two clamping arms 4 , 5 .

[0108] The insulating bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com