Cleaning device for inner wall of industrial waste barrel in industrial park

A technology for industrial waste and industrial parks, which is applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., and can solve the problems that the residue cannot be cleaned, the cleaning efficiency of the inner wall of the waste barrel is low, and the effect is poor and costly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

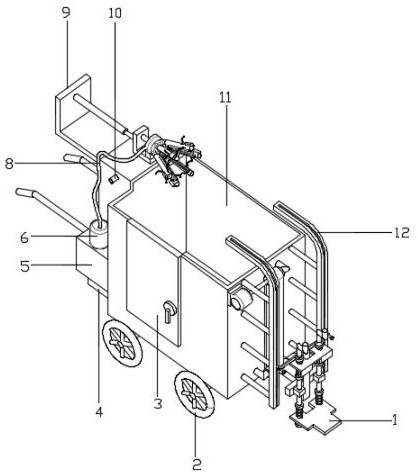

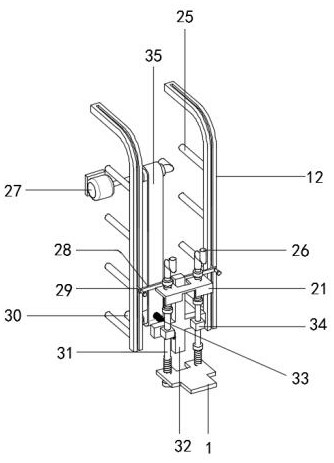

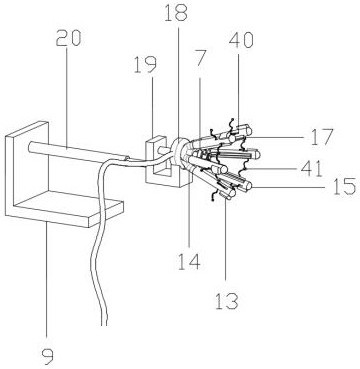

[0031] refer to Figure 1-5 , the cleaning device for the inner wall of the industrial waste barrel in the industrial park, including the water delivery pipe 10, the garbage truck 11 and the cylinder 23, the outer wall of one side of the garbage truck 11 is fixed with a fixed shaft 30 by screws, and the outer wall of the fixed shaft 30 is connected with a transmission through a roller sleeve. Chain 35, and one side outer wall of roller is connected with motor 27 by bolt, and one side outer wall of transmission chain 35 is welded with fixed rod 33, and one end of fixed rod 33 is connected with lifting frame 32 by hinge, and one side of lifting frame 32 is arranged There is a sliding mechanism, one side outer wall of the garbage truck 11 is fixed with a strut 25 by a bolt, one end of the strut 25 is fixed with a slide rail 12 by a bolt, and one side outer wall of the lifting frame 32 is fixed with a base block 34 by a bolt, and the base block 34 The top inner wall of the garbage...

Embodiment 2

[0041] refer to Image 6 , the cleaning device for the inner wall of the industrial waste barrel in the industrial park. Compared with Embodiment 1, the inner wall of the garbage truck 11 is fixed with a filter screen 36 by bolts, and the top of the outer wall of one side of the garbage truck 11 is fixed with a sewage pipe by bolts. 37.

[0042] In the present invention, one side outer wall of the garbage truck 11 is connected with a box door 3 through a hinge, and the top outer wall of the garbage truck 11 is connected with a wheel 2 through a fixed shaft.

[0043] During use, the wheel 2 is used to drive the garbage truck 11 to move its position by pushing the handle, and the sewage generated after washing is filtered by the filter screen 36 and collected at the bottom of the garbage truck 11, and finally the sewage is discharged by opening the sewage pipe 37, and the box door 3 is opened at the same time. Take out the filtered garbage residue,

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com