Stirring device for building decoration paint

A technology of stirring device and coating, which is applied to mixers with rotary stirring devices, accessories of mixers, transportation and packaging, etc., can solve the problems of difficult mixing and mixing of large-particle coating materials, insufficient mixing, and difficult cleaning. , to avoid the existence of large particles or undissolved coatings, and achieve the effect of efficient stirring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

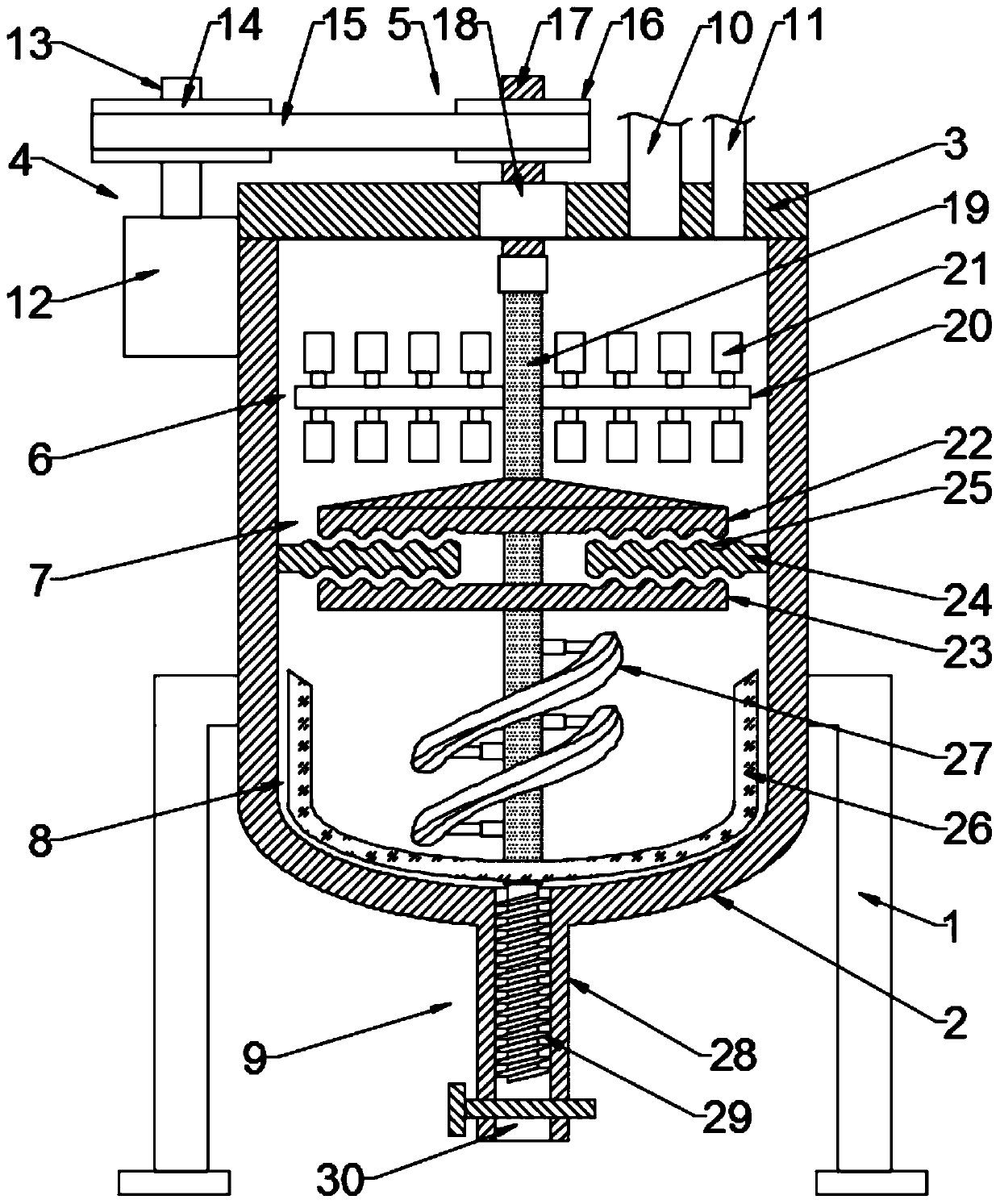

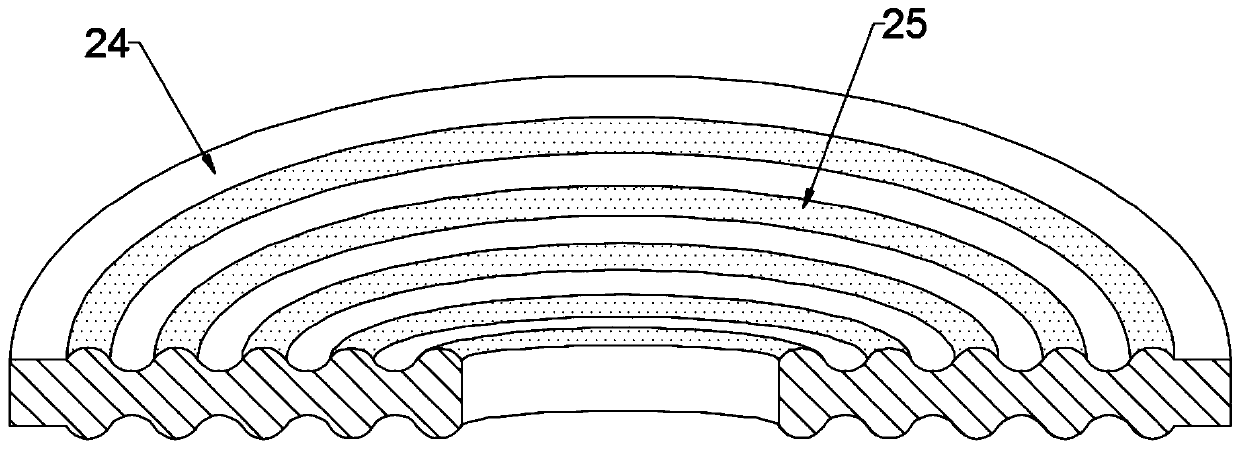

[0025] see Figure 1 ~ Figure 2 , a stirring device for architectural decoration coatings, comprising a mixing barrel 2, a driving mechanism 4, a transmission mechanism 5, a stirring mechanism 6, a grinding mechanism 7, a scraping assembly 8 and an extrusion mechanism 9, and the mixing barrel 2 is fixed on a supporting base 1, a bucket cover 3 is installed on the upper end of the mixing tank 2, and a stirring mechanism 6, a grinding mechanism 7, a scraping assembly 8 and an extrusion mechanism 9 are installed in the mixing bucket 2 from top to bottom, and the top of the mixing bucket 2 is provided with The transmission mechanism 5 is connected to the stirring mechanism 6 , and the transmission mechanism 5 is connected to the driving mechanism 4 .

[0026] see figure 1 and figure 2 As shown, the drive mechanism 4 includes a drive motor 12, a drive shaft 13 and a drive sprocket 14, the drive motor 12 is a servo motor with forward and reverse functions, and the drive motor 12 ...

Embodiment 2

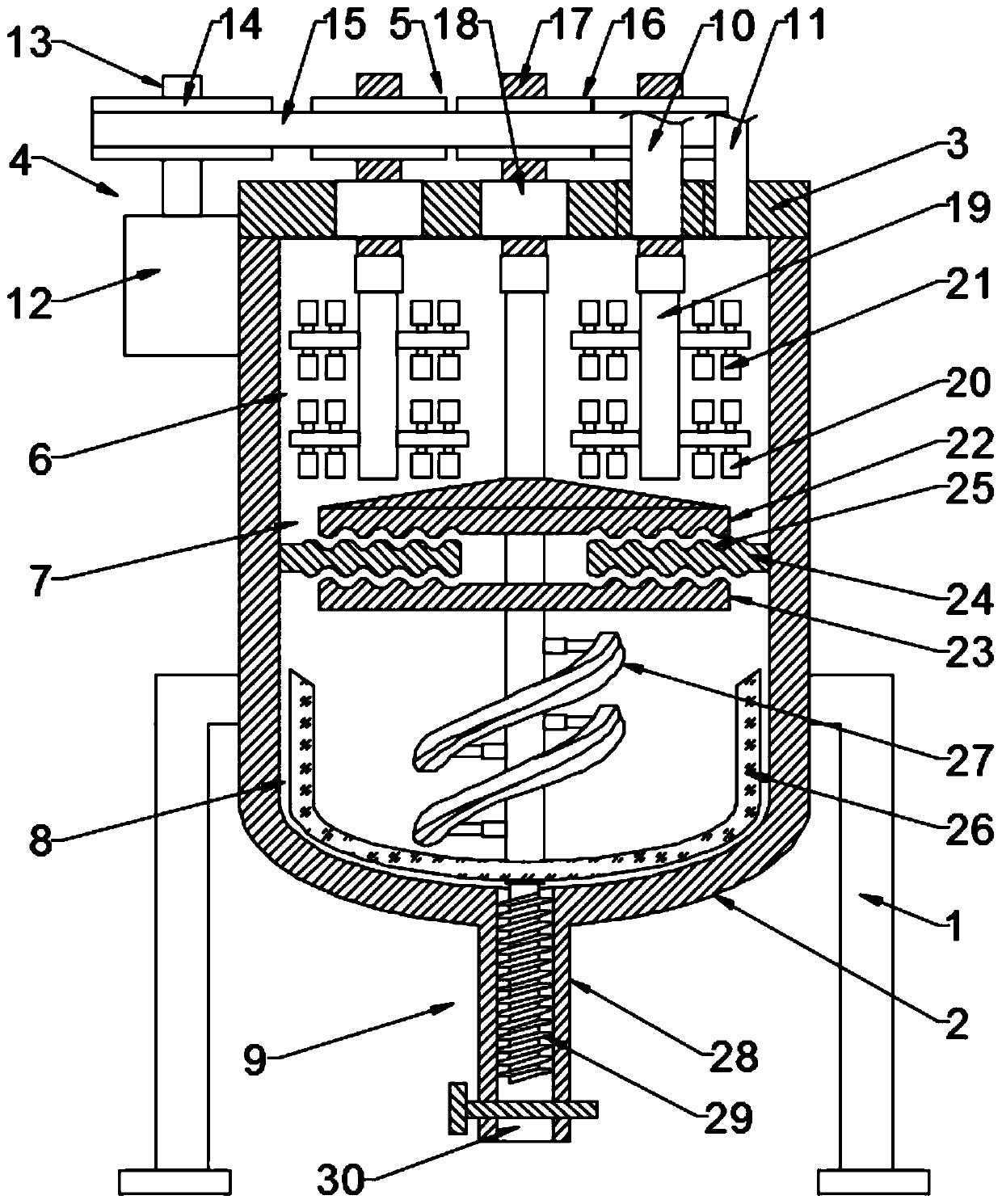

[0035] A stirring device for building decoration coatings, comprising a stirring barrel 2, a driving mechanism 4, a transmission mechanism 5, a stirring mechanism 6, a grinding mechanism 7, a scraping assembly 8 and an extrusion mechanism 9, the stirring barrel 2 is fixed on a support base 1 On the upper end of the mixing barrel 2, a barrel cover 3 is installed, and the stirring barrel 2 is installed with a stirring mechanism 6, a grinding mechanism 7, a scraping assembly 8 and an extrusion mechanism 9 from top to bottom, and the top of the mixing barrel 2 is provided with a transmission The mechanism 5 and the transmission mechanism 5 are connected to the stirring mechanism 6 , and the transmission mechanism 5 is connected to the driving mechanism 4 .

[0036] Described drive mechanism 4 comprises drive motor 12, drive shaft 13 and drive sprocket 14, and drive motor 12 is the servomotor with forward and reverse function, and drive motor 12 is installed on the motor seat of mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com