Vertical shaft stirrer

A mixer and vertical shaft technology, applied in the field of mixing equipment and vertical shaft mixers, can solve the problems that the materials in the tank cannot be fully mixed, the effect of mixing and mixing is affected, and the material utilization is insufficient, so as to achieve high practicability and market competitiveness. Mixing efficiency and mixing uniformity, the effect of low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

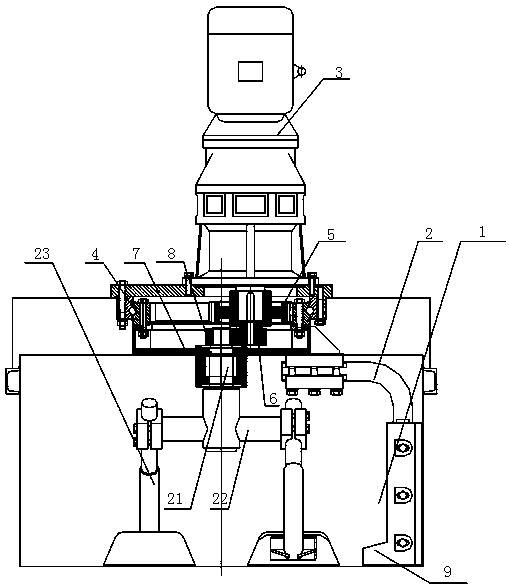

[0030] Such as figure 1 As shown, this embodiment provides a vertical shaft mixer, which mainly overcomes the problems of low mixing efficiency in the prior art, uneven mixing of materials and easy accumulation on the inner wall of the tank. The vertical shaft mixer mainly includes a power mechanism 3, a stirring tank Tank body 1, stirring arm, slewing bearing, scraping arm 2 and other parts.

[0031] Power mechanism, the general power mechanism is composed of a motor and a reducer. On this basis, the output shaft of the power mechanism is the output shaft of the reducer. In addition, the power mechanism can also use other power systems such as geared motors and hydraulic motors. It belongs to the existing mature technology, so this embodiment will not repeat it. The power mechanism has an output shaft, and in this embodiment, a duplex gear is sleeved on the output shaft. The term "dual gear" refers to a gear with two gears superimposed and connected as one structure. For th...

Embodiment 2

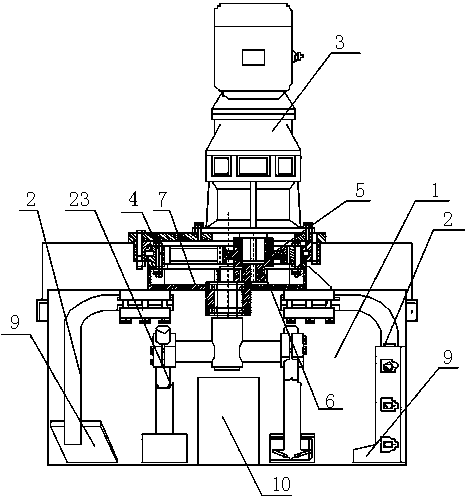

[0042] Such as figure 2 As shown, the differences between this embodiment and Embodiment 1 are: 1. The number of scraping arms is two; The steel pipe is used to prevent materials from accumulating in the central area of the stirring tank body 1 .

Embodiment 3

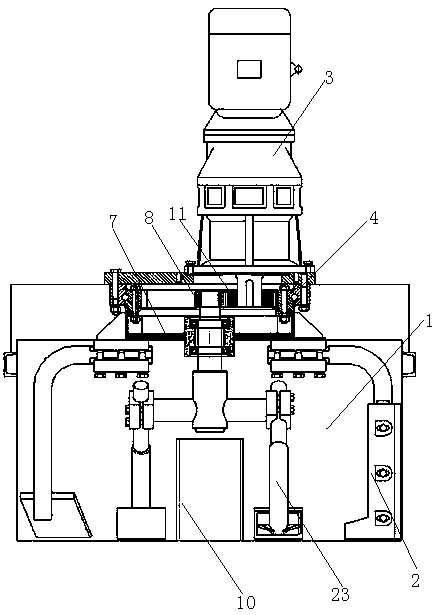

[0044] Such as image 3 , 4 As shown, the difference between this embodiment and Embodiments 1 and 2 is that the gear linkage mechanism includes an output tooth 11 sleeved on the output shaft of the power mechanism 3, and the right end of the output tooth 11 is connected to the inner ring of the inner ring of the slewing bearing 4. Teeth mesh, and its left end meshes with meshing gear 8. On the basis of the above structure, the connecting turntable 7 is in the shape of an inner hollow disc, with an opening at its upper end, and a connecting plate for connecting with the inner ring of the slewing bearing on the edge of the upper end; the connecting shaft of the stirring arm passes through the connecting The turntable extends into the inner ring of the slewing support, and the meshing gear 8 sleeved on the end of the connecting shaft meshes with the output teeth 11 in the inner ring of the slewing support.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com