Concentrated cotton removal device of roving frame

A technology of roving frames and cotton troughs, which is applied in the direction of textiles and papermaking, etc., which can solve the problems of large labor and time consumption, accumulation of waste flowers, and poor removal of waste flowers, so as to save labor, improve efficiency, and achieve good cotton removal effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

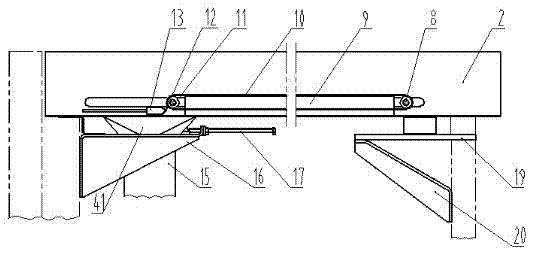

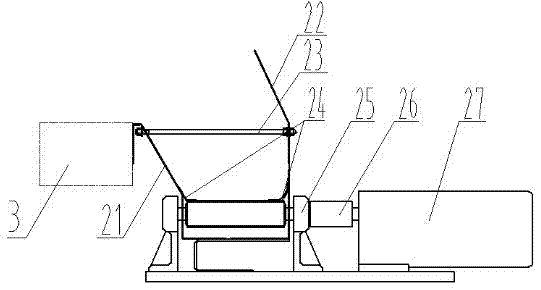

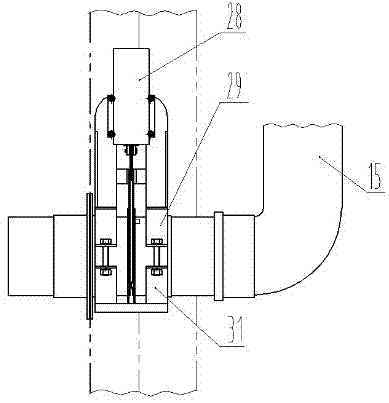

[0021] Example : A centralized cotton removal device for a roving frame, such as figure 1 As shown, it includes a cotton removal tank 2, an endless belt 10, a cleaning scraper 12, a waste flower discharge port 41 and an air duct 15. Cotton removal slot 2 extends along the horizontal direction, from figure 2 It can be seen from the side view that the cotton removal tank 2 is formed by extending upwards from a U-shaped structure at the bottom to form two front and rear side walls 21, 22 inclined in the same direction, wherein the front side wall is fixed on the vehicle surface 3, The rear side wall 22 is higher than the front side wall 21, and the top end of the front side wall 21 is connected to the bottom end of the rear side wall 22 by pins 23, and the rear side wall 22 located above is inclined inwardly so that waste flowers can be blocked in the cotton removal groove 2 within. In the cotton removal tank 2, an endless belt 10 is arranged, and the endless belt 10 is slee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com