Printing press with a washing device for an inking unit

A technology for printing presses and inking, which is used in printing presses, general parts of printing machinery, printing, etc., and can solve problems such as problems with ink replacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

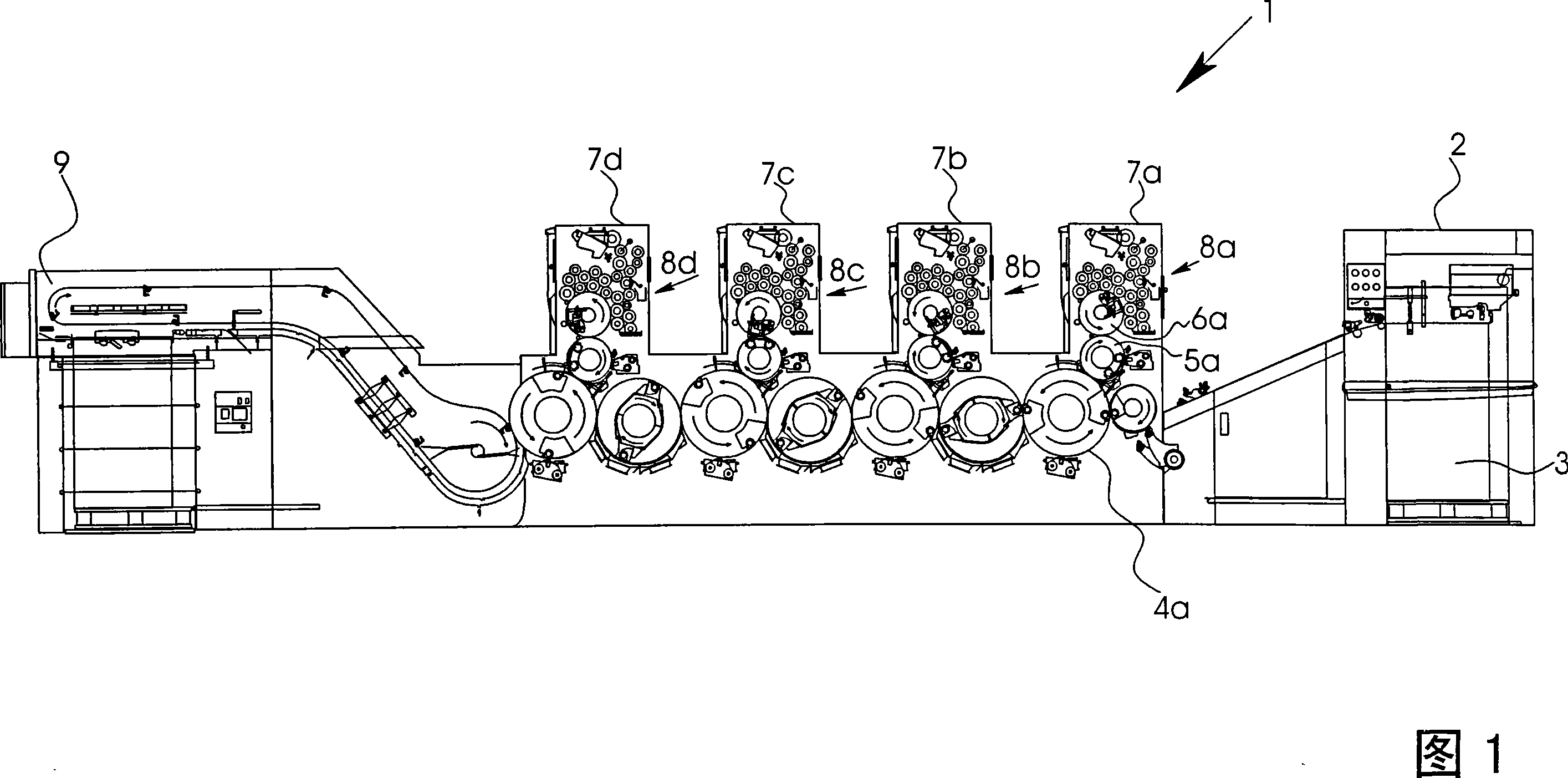

[0038] Figure 1 shows an offset printing press 1 in a tandem configuration with a feeder 2 and four printing units 7a-d for the four primary colors black, yellow, magenta and cyan, on which an unprinted stack 31 is located. device. The delivery 9 of the printing press follows the fourth printing unit 7d. The gripper bridge runs around the delivery with the aid of a chain guide. The gripper bridge picks up the printed sheet and transports it to the sheet stack, where it is deposited.

[0039]Each of the four printing units 7 a - d has an impression cylinder 4 , a blanket cylinder 5 and a printing form cylinder 6 , on which the respective printing form is tensioned. The printing plates are inked by means of inking units 8a-d, which will be described in more detail below.

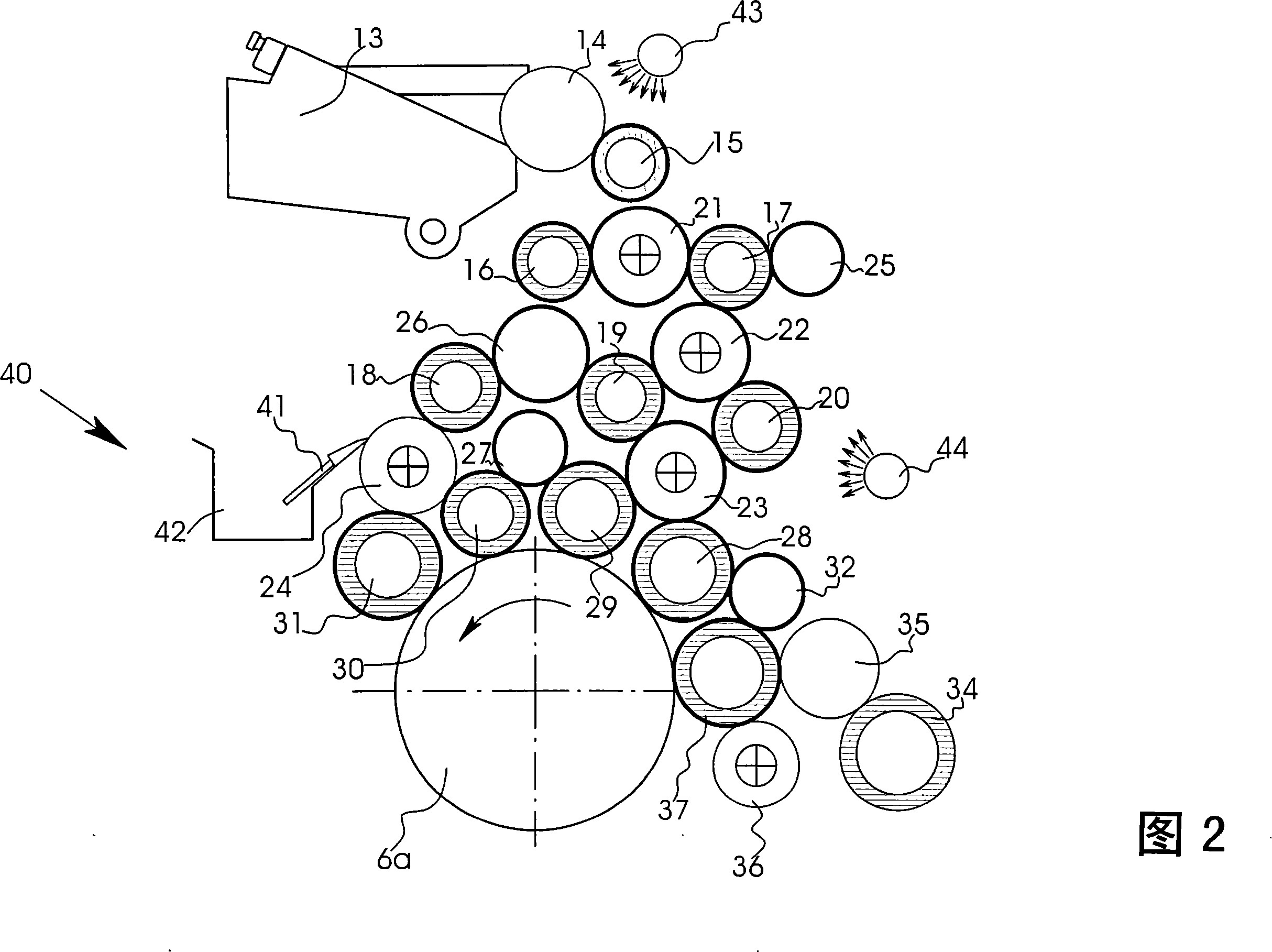

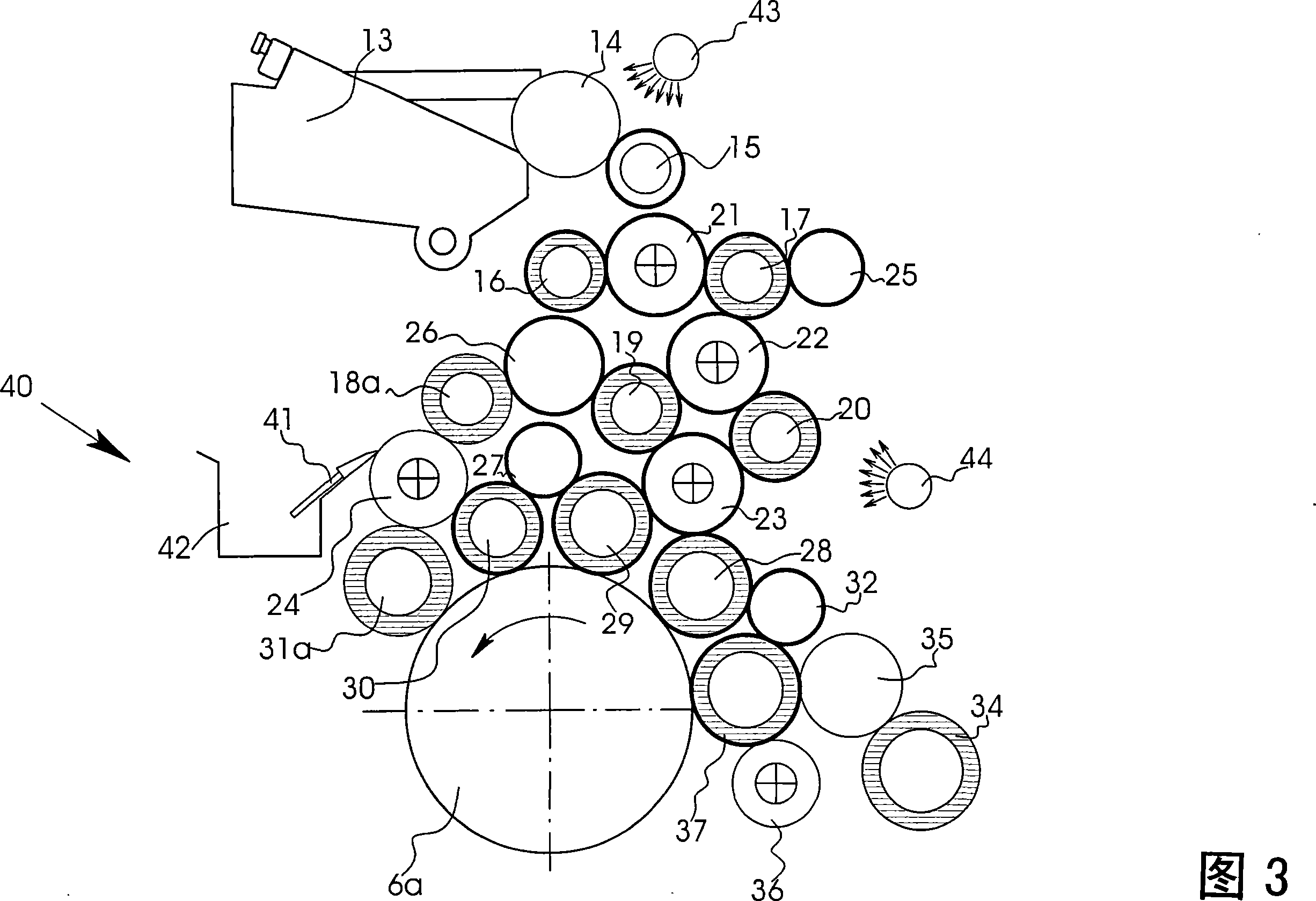

[0040] The inking unit shown in Figure 2 consists of a knife cartridge 13, an ink fountain roller 14, four inking rollers 28, 29, 30 and 31 and a series of further rollers 15 to 27, through which the inking...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com