Method for manufacturing wiring board having protective film

A manufacturing method and wiring board technology, which are applied in the directions of printed circuit manufacturing, coating of non-metallic protective layers, and secondary processing of printed circuits, can solve the problems of insufficient reduction of voids, complicated manufacturing processes of printed circuit boards, etc., to prevent Effects of voids, improved hiding, and improved photocurability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

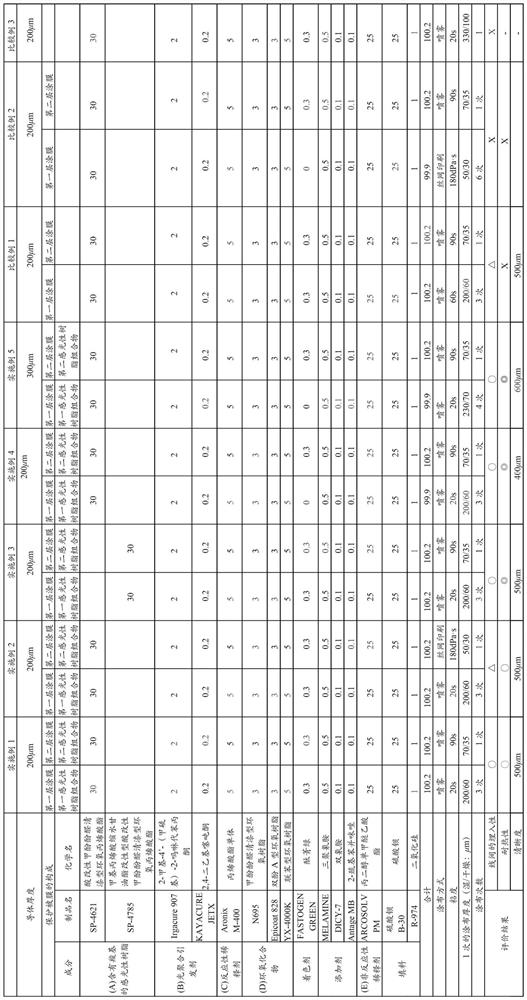

Embodiment 1~5、 comparative example 1~3

[0089] Mix the ingredients shown in the following Table 1 according to the proportions shown in the following Table 1, mix and disperse them at room temperature using triple rolls, and prepare the first photosensitive materials used in Examples 1-5 and Comparative Examples 1-3. Resin composition and the second photosensitive resin composition. Regarding the measurement of the viscosity of the first photosensitive resin composition and the second photosensitive resin composition, when using the Iwata cup to measure the viscosity (in the following Table 1, the unit of viscosity is "s"), when using NK-2 (ANEST IWATA Corporation) to measure rotational viscosity (in the following Table 1, the unit of viscosity is "dPa·s"), a Brookfield B-type viscometer (sample temperature 25° C., rotational speed 50 rpm, Brookfield Corporation) was used. Then, the prepared 1st photosensitive resin composition and the 2nd photosensitive resin composition were apply|coated as follows, and the test b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com