Black photosensitive resin composition

A photosensitive resin and composition technology, applied in optics, optomechanical equipment, photosensitive materials for optomechanical equipment, etc., can solve the problem of insufficient light curing in the depth of the solder resist coating, and it is difficult to reach the depth of the solder resist coating. problems, such as increased light absorption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

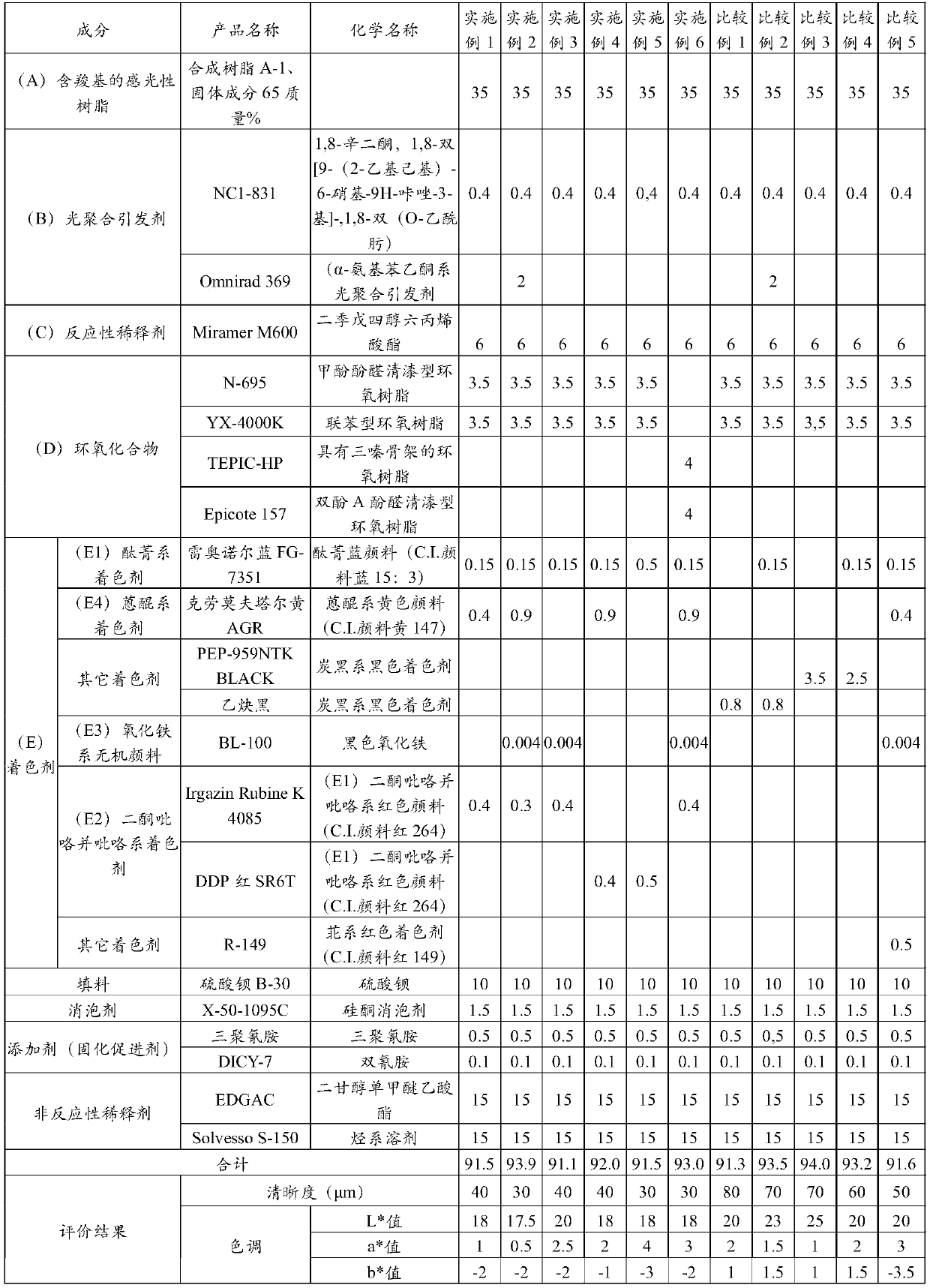

Embodiment 1~6、 comparative example 1~5

[0080] Add the components shown in the following Table 1 according to the ratio shown in the following Table 1, and use a three-roll mill to mix and disperse at room temperature (about 25° C.) to prepare the compounds used in Examples 1 to 6 and Comparative Examples 1 to 5. A black photosensitive resin composition. Unless otherwise specified, the numbers in Table 1 below represent parts by mass. In addition, blank columns in the following Table 1 indicate that they were not added.

[0081] In addition, each component in Table 1 is explained in detail below.

[0082] (A) Carboxyl-containing photosensitive resin

[0083] In 250 parts by mass of carbitol acetate, dissolve 220 parts by mass of cresol novolak type epoxy resin (Sumitomo Chemical Industries, Ltd., ESCN-220, epoxy equivalent weight 220) and 72 parts by mass of acrylic acid, and React under reflux to obtain cresol novolak type epoxy acrylate. Next, add 138.6 parts by mass of hexahydrophthalic anhydride to the obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com