LED-UV ink for high-speed double-sided printing and preparation method thereof

A LED-UV, double-sided printing technology, applied in the field of ink, can solve the problems of high energy consumption, long curing time, low printing efficiency, etc., and achieve high film forming hardness, fast curing reaction, wear resistance and adhesion high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] A LED-UV ink for high-speed double-sided printing, prepared from the following raw materials in parts by weight:

[0049]

[0050]

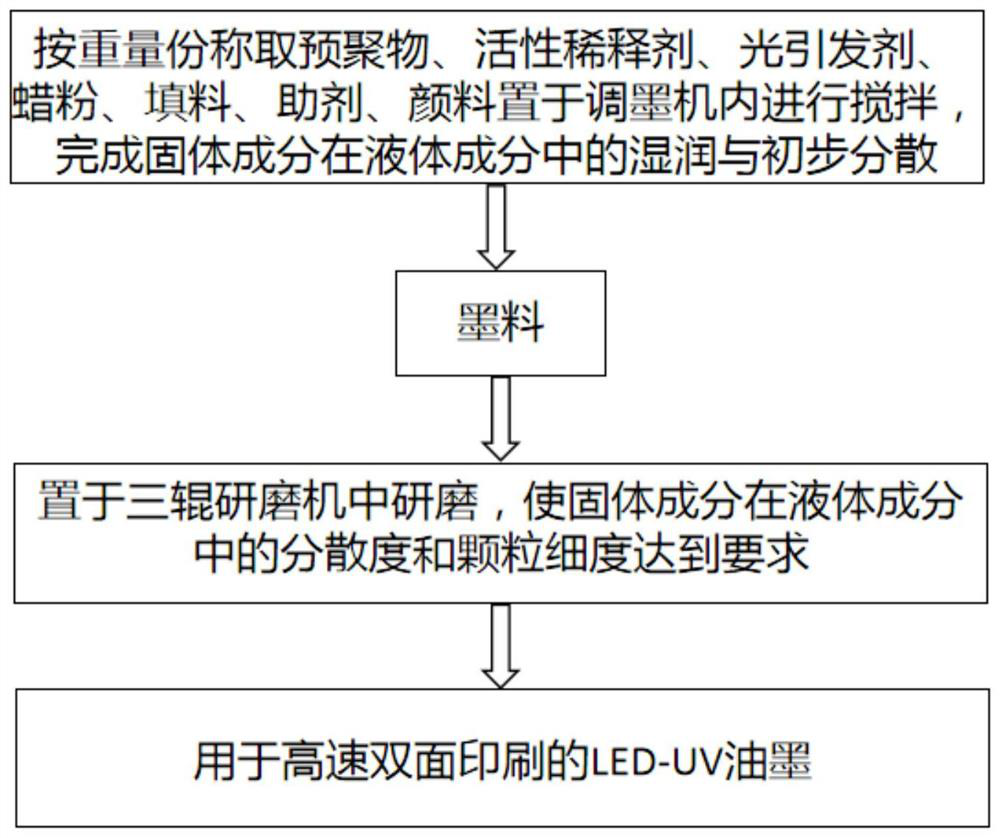

[0051] The preparation method comprises the following steps:

[0052] (1) Weigh the prepolymer, reactive diluent, photoinitiator, wax powder, filler, auxiliary agent, and pigment by weight and place them in the ink mixer for stirring to complete the wetting and preliminary dispersion of the solid components in the liquid components , get the ink;

[0053](2) Put the ink material obtained in step (1) into a three-roller grinder and grind it under light-shielding conditions until the fineness of the ink reaches below 10 μm to obtain the LED-UV for high-speed double-sided printing ink.

Embodiment 2

[0055] A LED-UV ink for high-speed double-sided printing, prepared from the following raw materials in parts by weight:

[0056]

[0057]

[0058] The preparation method is the same as in Example 1.

Embodiment 3

[0060] A LED-UV ink for high-speed double-sided printing, prepared from the following raw materials in parts by weight:

[0061]

[0062]

[0063] The preparation method is the same as in Example 1.

[0064] In embodiment 1-3, polyurethane acrylate adopts aliphatic polyurethane acrylate Laromer UA9033 (Germany BASF); Polyester acrylate adopts polyester acrylate Laromer LR 9004 (Germany BASF); Polytetrafluoroethylene wax powder adopts polytetrafluoroethylene Ethylene wax micropowder PTFE-0101 (Nanjing Tianshi New Material Technology Co., Ltd.); polyamide wax powder adopts micronized polyamide wax powder Crayvallac LV (France Arkema); ultrafine calcium carbonate adopts nano calcium carbonate (particle size 20nm, Shanghai Naiou Nano Technology Co., Ltd.); the wetting and dispersing agent adopts modified polyether wetting and dispersing agent TEGO Dispers 650 (Evonik Tego); the leveling agent adopts polyether modified polysiloxane leveling agent BYK -UV 3500 (Bick, Germany)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com